Etching solution composition

A technology of composition and etching solution, applied in the direction of instruments, electrical components, circuits, etc., can solve the problems of low heat resistance of photoresist, melting and deformation of photoresist, and achieve improved stability and uniformity. Sex, the effect of suppressing unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

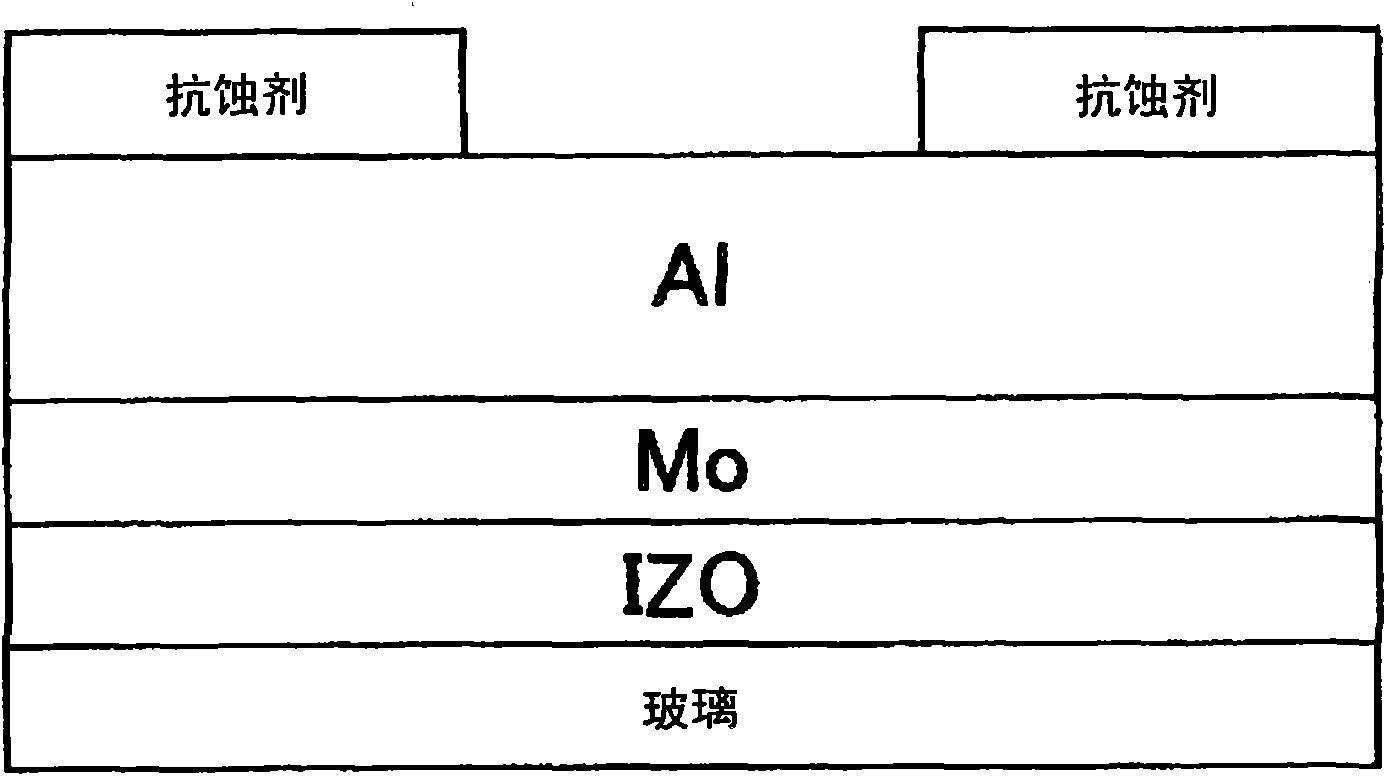

[0109] 48.3 g of ammonia water (29% by weight), 9.7 g of hydrogen peroxide water (31% by weight), and 142 g of water were added to a 200 ml beaker to prepare an etching solution consisting of 200 g of an aqueous solution of 7% by weight of ammonia and 1.5% by weight of hydrogen peroxide. combination.

[0110] (Evaluation experiment 1)

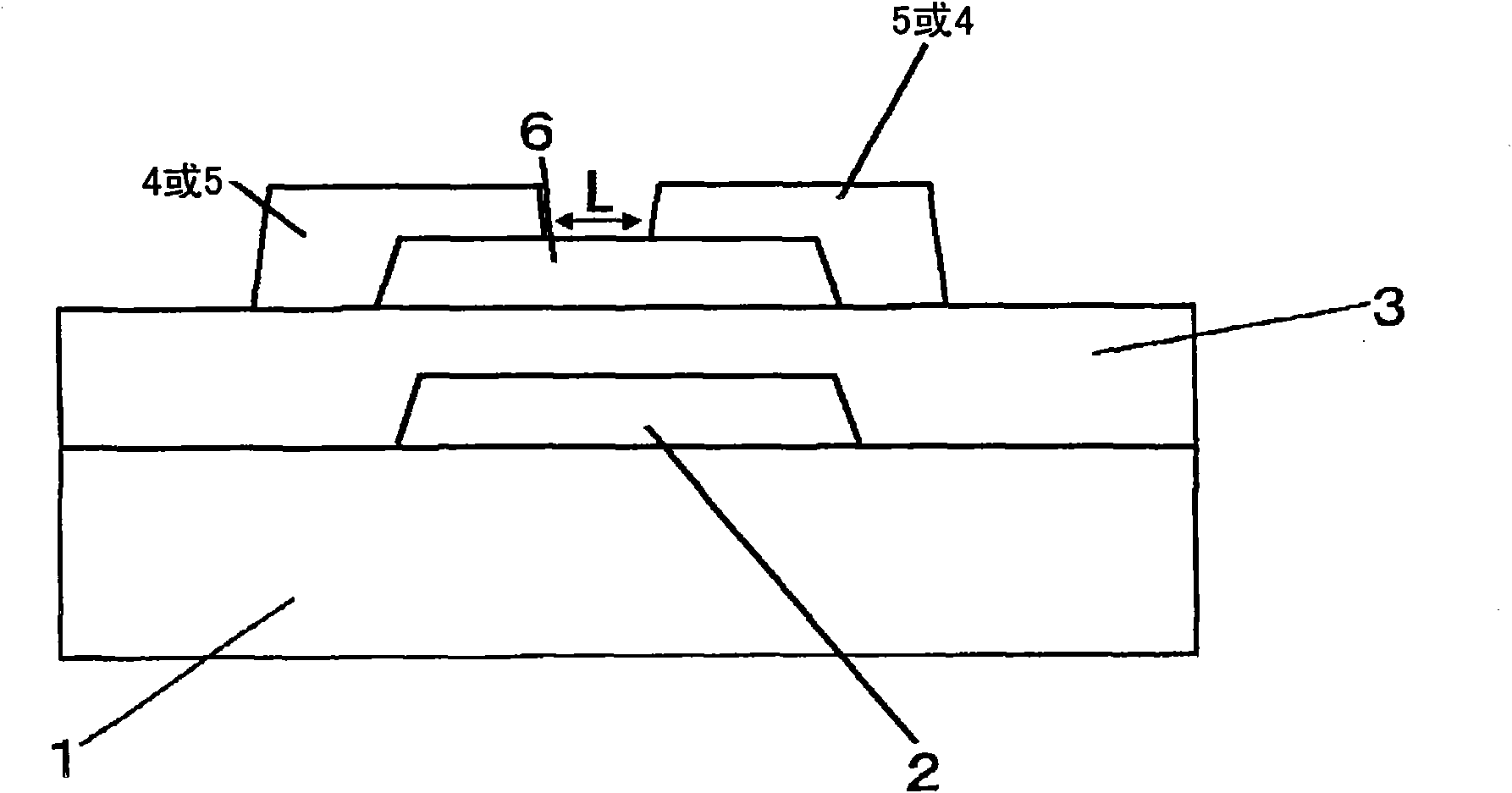

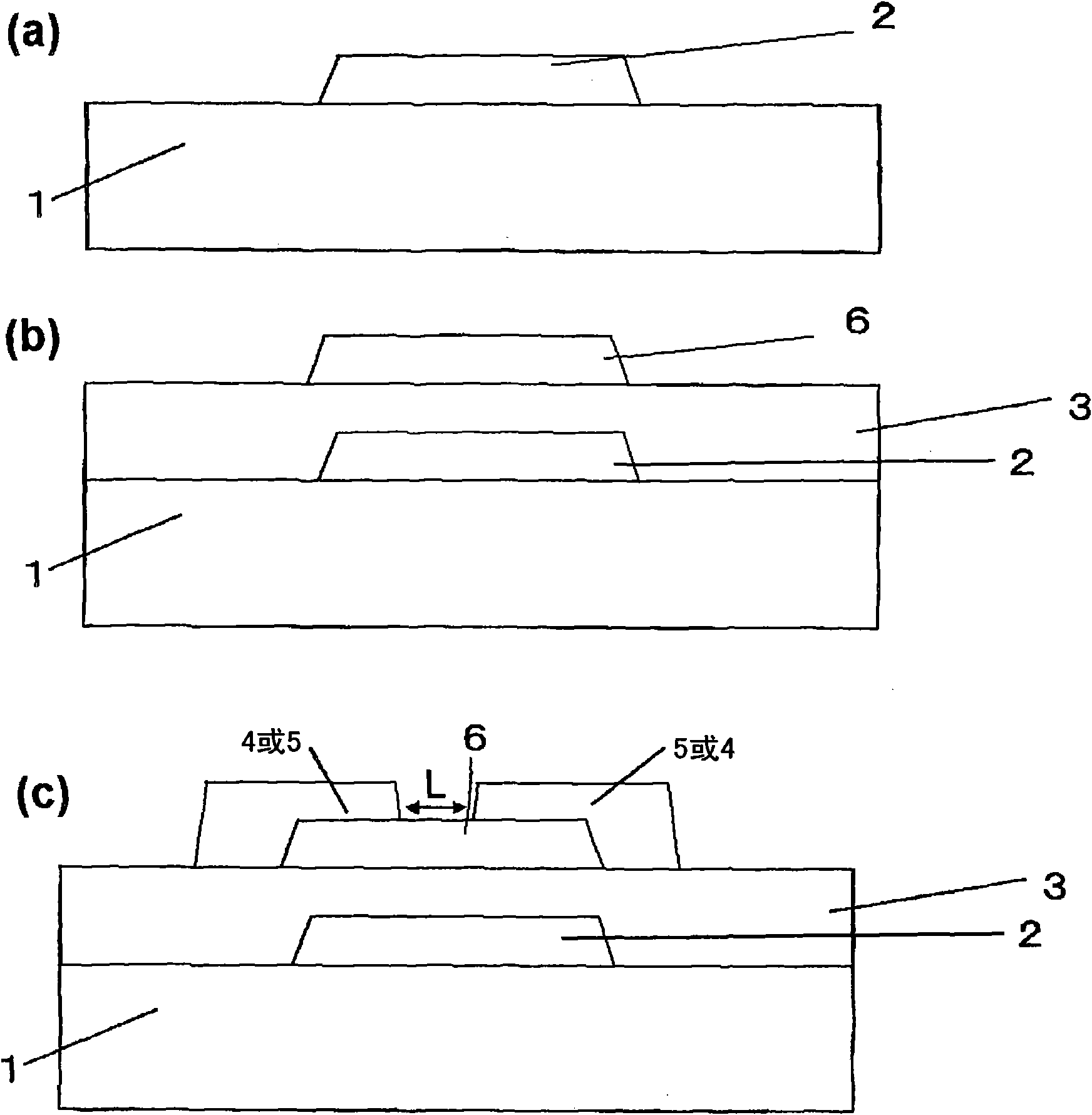

[0111] In the prepared alkaline etchant composition, submerged into the patterned positive resist / Al / Mo / IZO The etching rate of the Al / Mo laminated film was obtained by visually measuring the appropriate etching time of the Al / Mo laminated film on a substrate made of glass. The results are shown in Table 1.

Embodiment 2~15

[0113] An etching solution composition was prepared in the same manner as in Example 1 except that the concentrations of ammonia and hydrogen peroxide were the concentrations shown in Table 1. Evaluation experiment 1 was performed on the prepared etching solution composition in the same manner as in Example 1, and the etching rate of the Al / Mo laminated film was calculated. The results are shown in Table 1.

[0114] Table 1

[0115]

Embodiment 16

[0125] The etching liquid composition shown in Table 4 was prepared similarly to Example 1 except having added ammonia and water so that ammonia might become 7 weight%.

[0126] Table 4

[0127] etchant

Ammonia (wt%)

Hydrogen peroxide (weight%)

Water (wt%)

Example 16

7

0

93

40

[0128] (Evaluation experiment 3)

[0129] The etching rate of Al, Cu, IZO, p-ITO or α-ITO film with the etching solution composition of Example 16 shown in Example 1 and Table 4 was measured. The results are shown in Table 5. In addition, the etching selectivity is shown in Table 6.

[0130] table 5

[0131]

[0132] Table 6

[0133] etchant

Al and IZO

selection ratio

Al and p-ITO

selection ratio

Al and α-ITO

selection ratio

Cu and IZO

selection ratio

Cu and p-ITO

selection ratio

Cu and α-ITO

selection ratio

Example 1

33.3∶1

10.3∶1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com