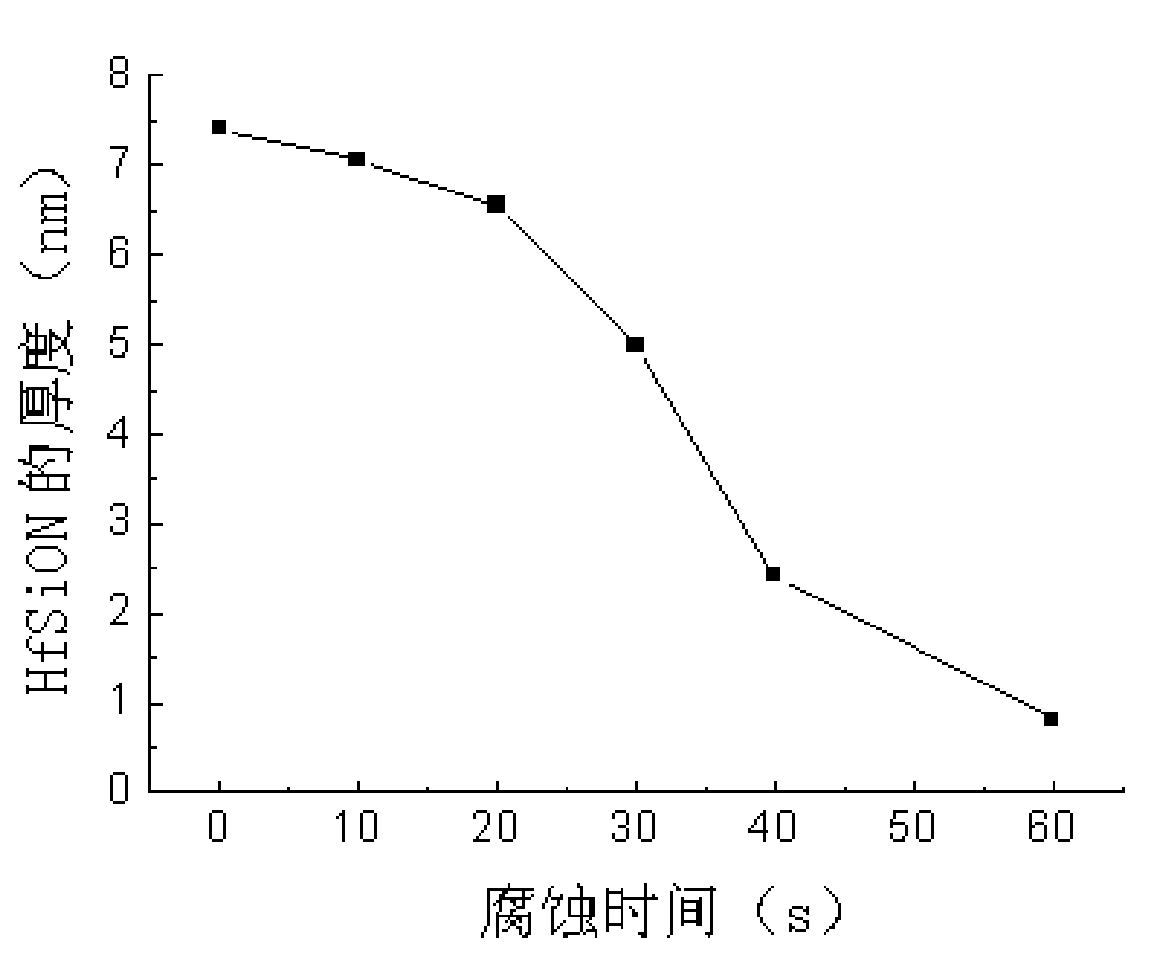

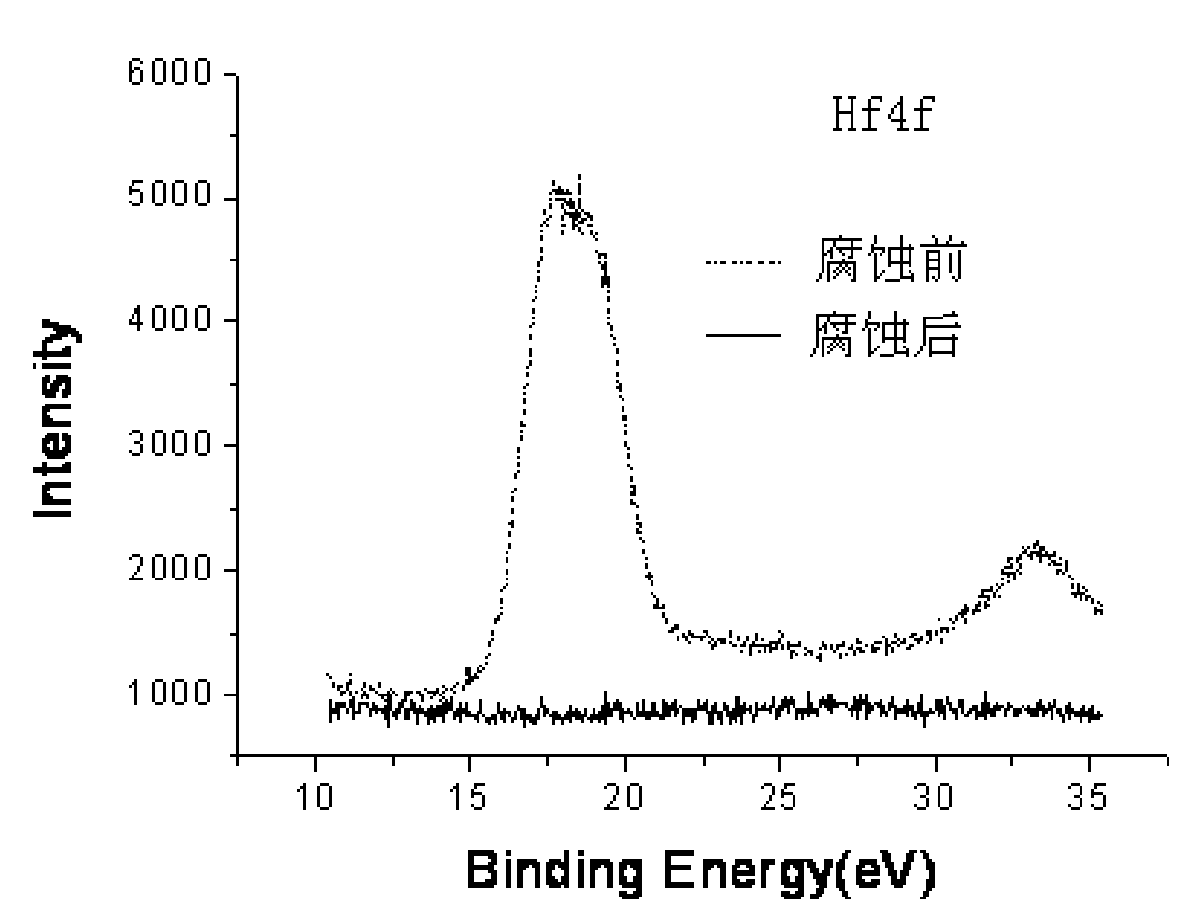

Corrosive agent and corrosion method of HfSiON high-K gate dielectric material

A gate dielectric and etchant technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of poor volatility of etching products, decreased device driving ability, and field oxide layer consumption, etc., to improve the corrosion rate and the selection ratio. , to achieve the effect of selective removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] In this embodiment 1, the etchant of the HfSiON high-K gate dielectric material includes 0.23%-4.06% hydrofluoric acid and 95.94%-99.77% water by weight percentage. In this embodiment, the concentration of the hydrofluoric acid is 40%, and the density is 1.13g / cm 3 .

Embodiment 2

[0031] In Embodiment 2, the etchant of the HfSiON high-K gate dielectric material includes 0.19%-4.24% hydrofluoric acid, 4.32%-54.57% inorganic acid and 41.19%-95.49% water by weight percentage. The inorganic acid includes one or more of hydrochloric acid, sulfuric acid and phosphoric acid, preferably, the inorganic acid is hydrochloric acid. In this embodiment, the concentration of the hydrofluoric acid is 40%, and the density is 1.13g / cm 3 ; The concentration of the hydrochloric acid is 37.5%, and the relative density is 1.18g / cm 3 ; The concentration of the sulfuric acid is 96%, and the relative density is 1.84g / cm 3 ; The concentration of the phosphoric acid is 85%, and the relative density is 1.84g / cm 3 .

[0032]When the inorganic acid is hydrochloric acid, the corrosive agent includes 0.22%-4.24% hydrofluoric acid, 4.32%-12.44% hydrochloric acid and 83.32%-95.46% water by weight percentage. When the inorganic acid is sulfuric acid, the corrosive agent includes 0.2%...

Embodiment 3

[0034] In this embodiment 3, the etchant of the HfSiON high-K gate dielectric material includes 0.22% to 4.83% of hydrofluoric acid, 5.31% to 58.14% of inorganic acid and 37.03% to 94.47% of organic solvent by weight percentage . The inorganic acid includes one or more of hydrochloric acid, sulfuric acid and phosphoric acid, preferably, the inorganic acid is hydrochloric acid. The organic solvent includes one or both of absolute ethanol and isopropanol, preferably, the organic solvent is absolute ethanol. In this embodiment, the concentration of the hydrofluoric acid is 40%, and the density is 1.13g / cm 3 ; The concentration of the hydrochloric acid is 37.5%, and the relative density is 1.18g / cm 3 ; The concentration of the sulfuric acid is 96%, and the relative density is 1.84g / cm 3 ; The concentration of the phosphoric acid is 85%, and the relative density is 1.84g / cm 3 .

[0035] When the inorganic acid is hydrochloric acid and the organic solvent is absolute ethanol, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com