Method for manufacturing crushing wall or rolling mortar wall pouring system of cone crusher during sand-coated casting of inner/outer metal molds

A cone crusher and metal mold sand coating technology, which is applied in the direction of manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve the problems of high cost, extensive molding methods, high labor intensity, etc. Inclusions and pores, strong erosion resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Manufacture Broken Wall Gating System

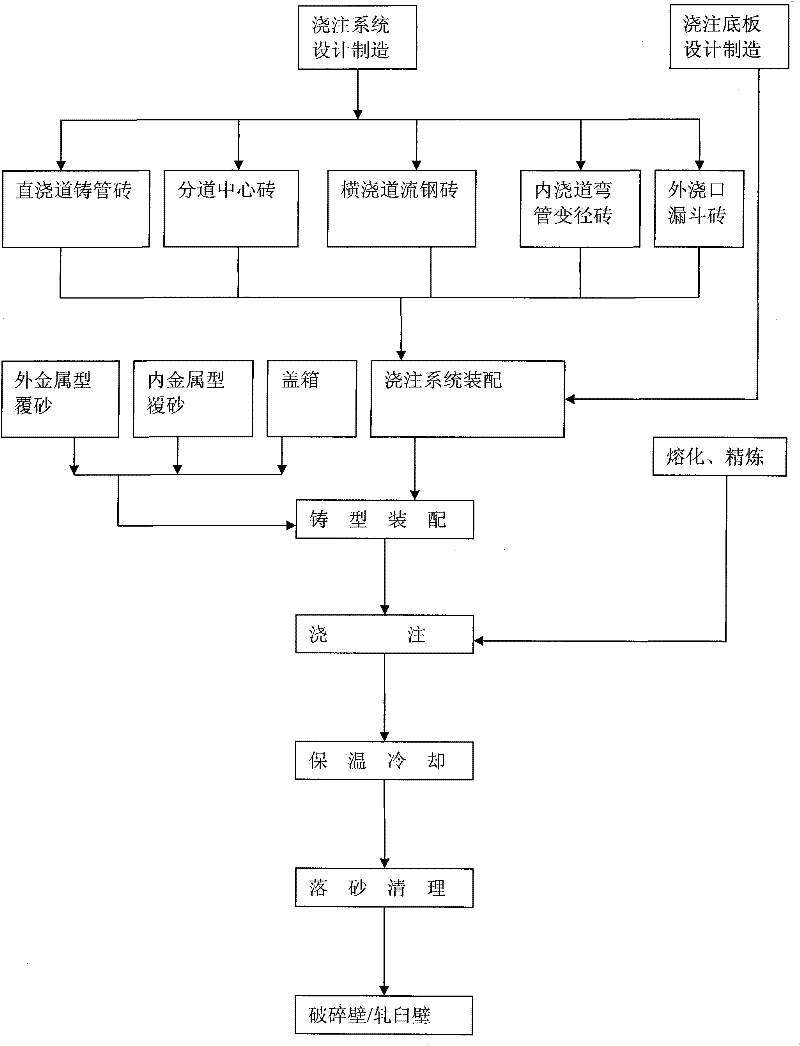

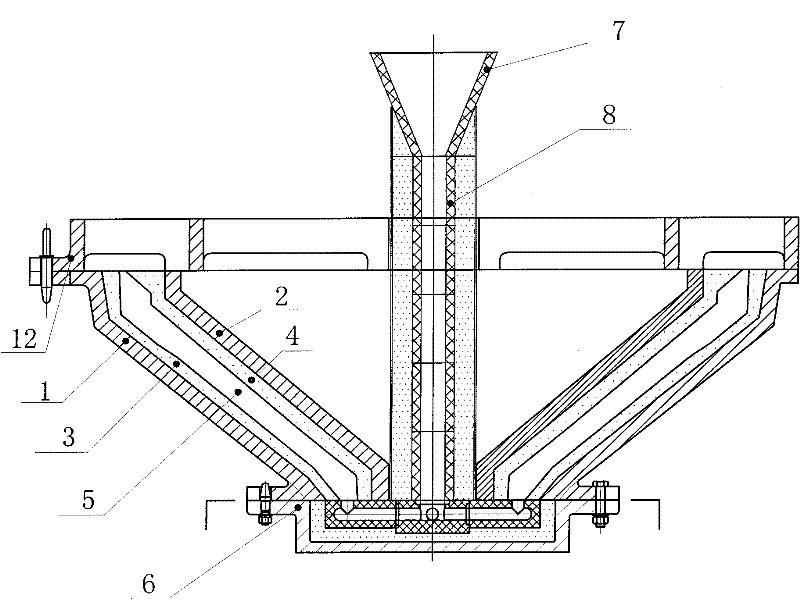

[0049] refer to figure 1 , 2 , 3, 6, its manufacture method step is as follows:

[0050] 1. Design and manufacture Each unit of the pouring system for broken wall castings:

[0051] (1) Choose the hole diameter D=40mm of the bottom injection ladle casting mouth brick;

[0052] (2) Design and manufacture sprue cast pipe brick 8 sprue hole diameter d = 70mm, wall thickness 25mm, material is refractory clay;

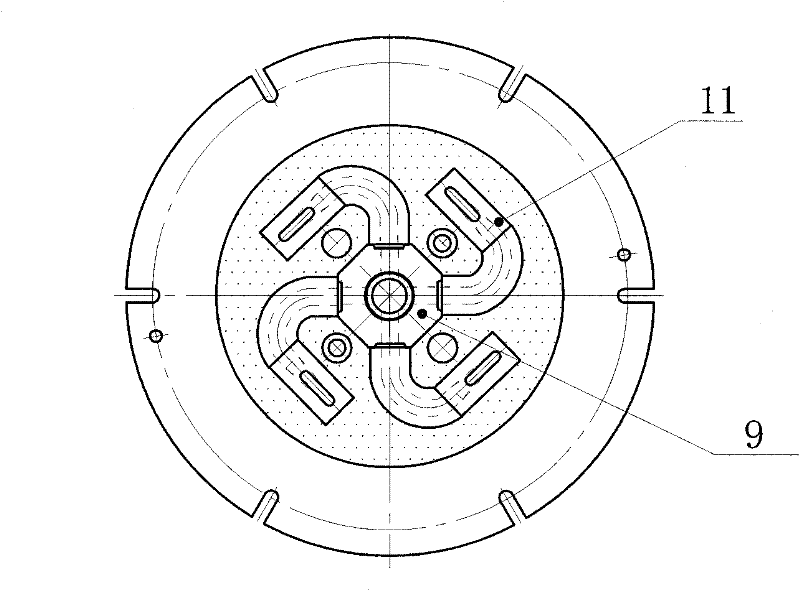

[0053] (3) Design and manufacture the four-hole lane-dividing central brick 9, the four-hole lane-dividing hole diameter d=35mm, the central hole diameter D=70mm, and the material is the same as the sprue;

[0054] (4) Design and manufacture the inner sprue elbow reducing brick 11, the size of which is The material is the same as the sprue brick;

[0055] (5) Design and manufacture the outer sprue funnel brick 7, the diameter of the funnel hole d=70mm, matching with the sprue cast pipe brick 8 boxes;

[0056...

Embodiment 2

[0067] Example 2 Manufacture Rolling Mortar Wall Casting System

[0068] refer to figure 1 , 4 , 5, and 7, respectively assemble four runner flow steel bricks 10, after the positioning is correct, fill and scrape the gaps on both sides of the flow steel bricks with dry sand, and the rest of the steps are the same as in Example 1.

Embodiment 3

[0069] Example 3 Manufacture Broken Wall Gating System

[0070] refer to figure 1 , 8 , 9, 12, its manufacture method step is as follows:

[0071] 1. Design and manufacture Each unit of the pouring system for broken wall castings:

[0072] (1) Choose the bottom pouring ladle casting mouth brick aperture D = 50mm;

[0073] (2) Design and manufacture the sprue cast pipe brick 8, the sprue hole diameter d=70mm, the wall thickness 25mm, and the material is refractory clay;

[0074] (3) Design and manufacture the six-hole lane-dividing central brick 9, the diameter of the central hole d=70mm, the diameter of the six-way lane d=40mm, and the material is the same as that of the sprue cast pipe brick;

[0075] (4) Design and manufacture the inner sprue elbow reducing brick 11, the size of which is The material is the same as the sprue cast pipe brick 8;

[0076] (5) Design and manufacture the outer sprue funnel brick 7, the diameter of the funnel hole is 70 mm, which matche...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| flame retardant | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com