Method of extracting GaCl from carbonaceous mudstone

A carbonaceous mudstone and gallium chloride technology, applied in the field of gallium metal extraction, can solve the problems of unsuitable extraction and achieve the effects of low production cost, short and novel process flow, and easy operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

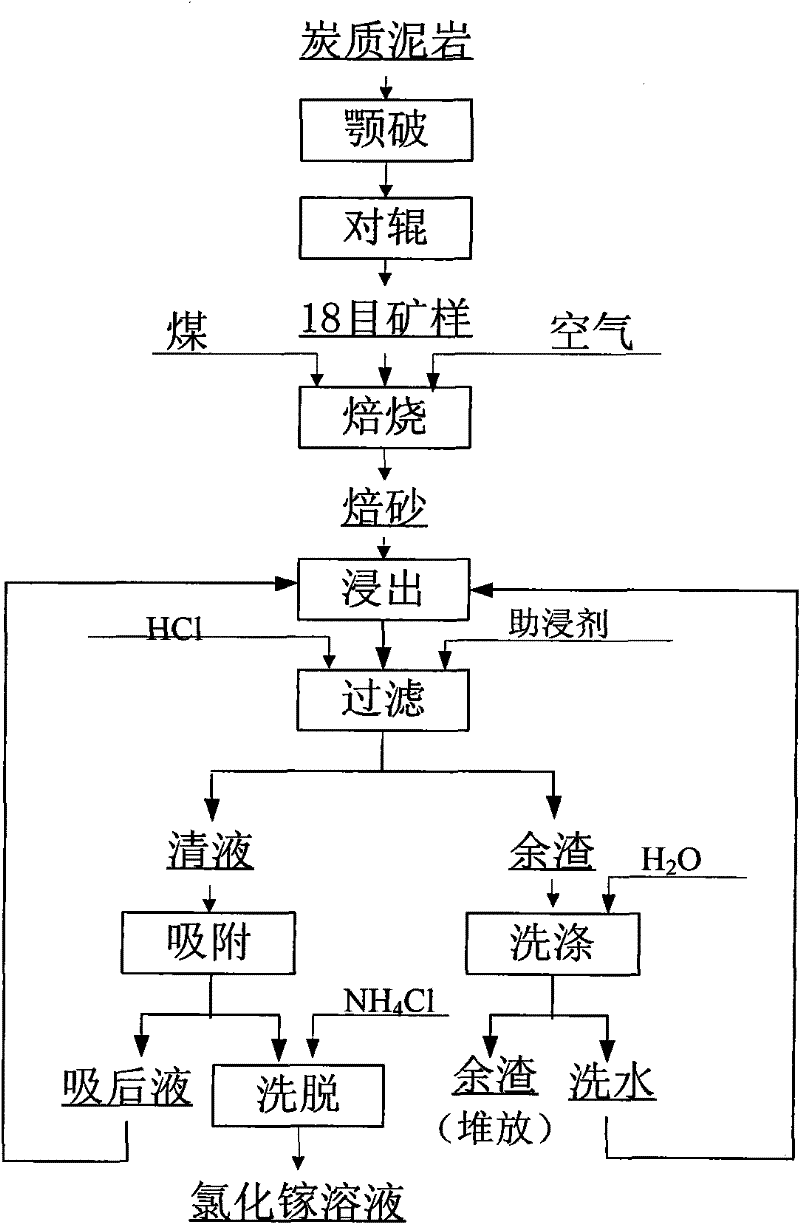

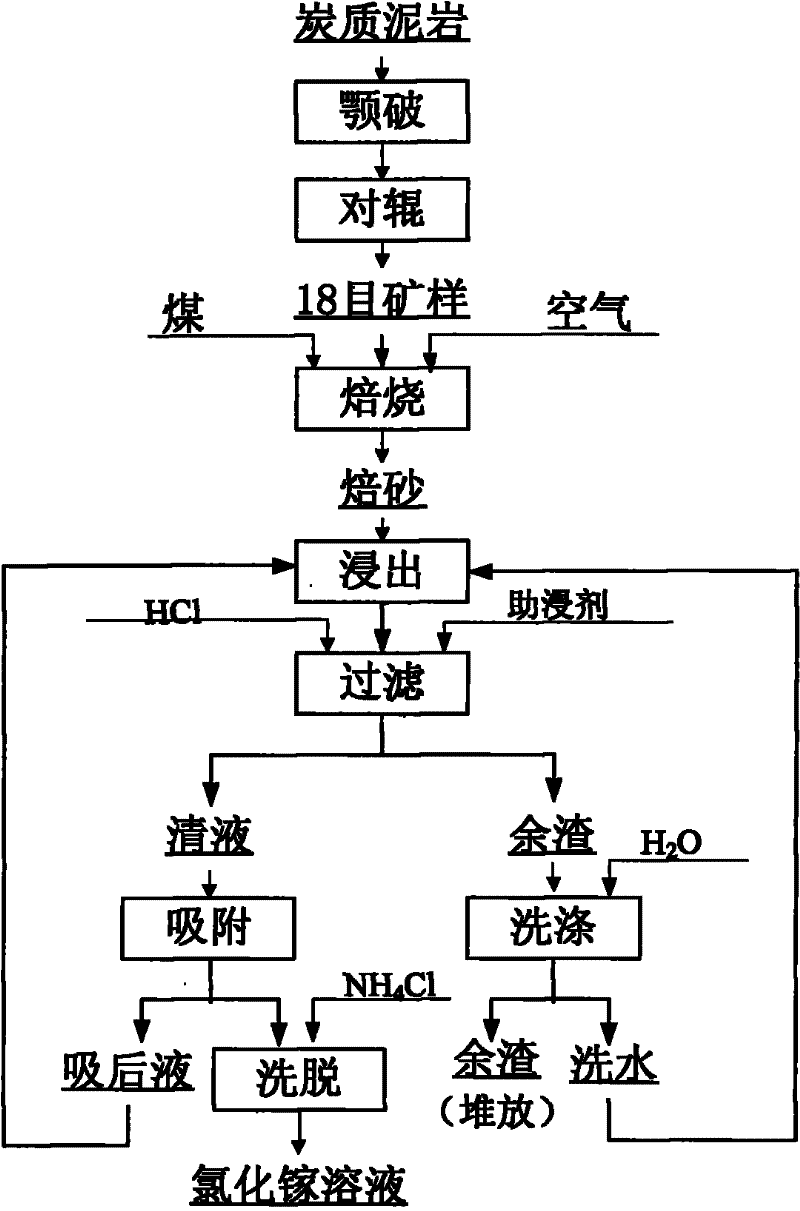

Method used

Image

Examples

Embodiment 1

[0030] 1) Carbonaceous mudstone is crushed to -18 mesh and made into mineral powder;

[0031] 2) Weigh 25.0 g of carbonaceous mudstone powder and roast it at 650°C for 2.0 hours to obtain calcined sand;

[0032] 3) Add 75ml of 5-10mol / L HCl and 5ml of leaching aid to the calcined sand for acid leaching. The leaching temperature is 95°C, the leaching time is 2.0h, the amount of leaching slag obtained after acid leaching is 12.0g, the analysis result shows that the gallium content is 0.00028%, and the calculated gallium leaching rate is 96.37%;

[0033] 4) The material after the leaching reaction is subjected to solid-liquid separation through a suction filter. The filter residue is washed with acidified water and piled up for construction materials or mine landfill. After washing, the water is returned for leaching and recycling. The supernatant liquid is eluted after adsorption, and the water after absorption is returned for use in the leachate.

[0034] 5) Collect 2L of le...

Embodiment 2

[0036] 1) Carbonaceous mudstone is crushed to -18 mesh and made into mineral powder;

[0037] 2) Weigh 25.0 g of carbonaceous mudstone mineral powder, and roast at 550° C. for 2.0 h to obtain calcined sand;

[0038] 3) Add 35ml of 8mol / L HCl and 5ml of leaching aid to the calcined sand, add water until the liquid-solid volume ratio is 4:1 and stir, then carry out acid leaching. The leaching temperature is 90°C, the leaching time is 2..5h, the amount of leaching slag obtained after acid leaching is 12.1g, the analysis result shows that the gallium content is 0.00032%, and the calculated gallium leaching rate is 95.57%;

[0039] 4) The material after the leaching reaction is subjected to solid-liquid separation through a suction filter. The filter residue is washed with acidified water and piled up for construction materials or mine landfill; the washed water is returned to leaching for recycling. The supernatant liquid is eluted after adsorption, and the water after absorptio...

Embodiment 3

[0042] 1) Carbonaceous mudstone is crushed to -18 mesh and made into mineral powder;

[0043] 2) Weigh 25.0 g of carbonaceous mudstone powder and roast it at 500°C for 1.5 hours to obtain calcined sand;

[0044]3) Add 35ml of 6.5mol / L HCl and 6ml of leaching aid to the calcined sand, add water until the volume ratio of liquid to solid is 2:1 and stir, then carry out acid leaching. The leaching temperature is 85°C, the leaching time is 2..5h, the amount of leaching slag obtained after acid leaching is 11.8g, the analysis result shows that the gallium content is 0.00019%, and the calculated gallium leaching rate is 97.55%;

[0045] 4) The material after the leaching reaction is subjected to solid-liquid separation through a suction filter. The filter residue is washed with acidified water and stacked for construction materials or mine landfill, and the washed water is returned to the leachate for recycling. The supernatant liquid is eluted after adsorption, and the water after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com