TFT-LCD array substrate and making method thereof

An array substrate and substrate technology, applied in the field of TFT-LCD array substrate and its manufacturing, can solve the problems of increased charging time, increased load of thin film transistors, and reduced charging capacity of thin film transistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0062] The technical solutions of the present invention will be described in further detail below with reference to the accompanying drawings and embodiments.

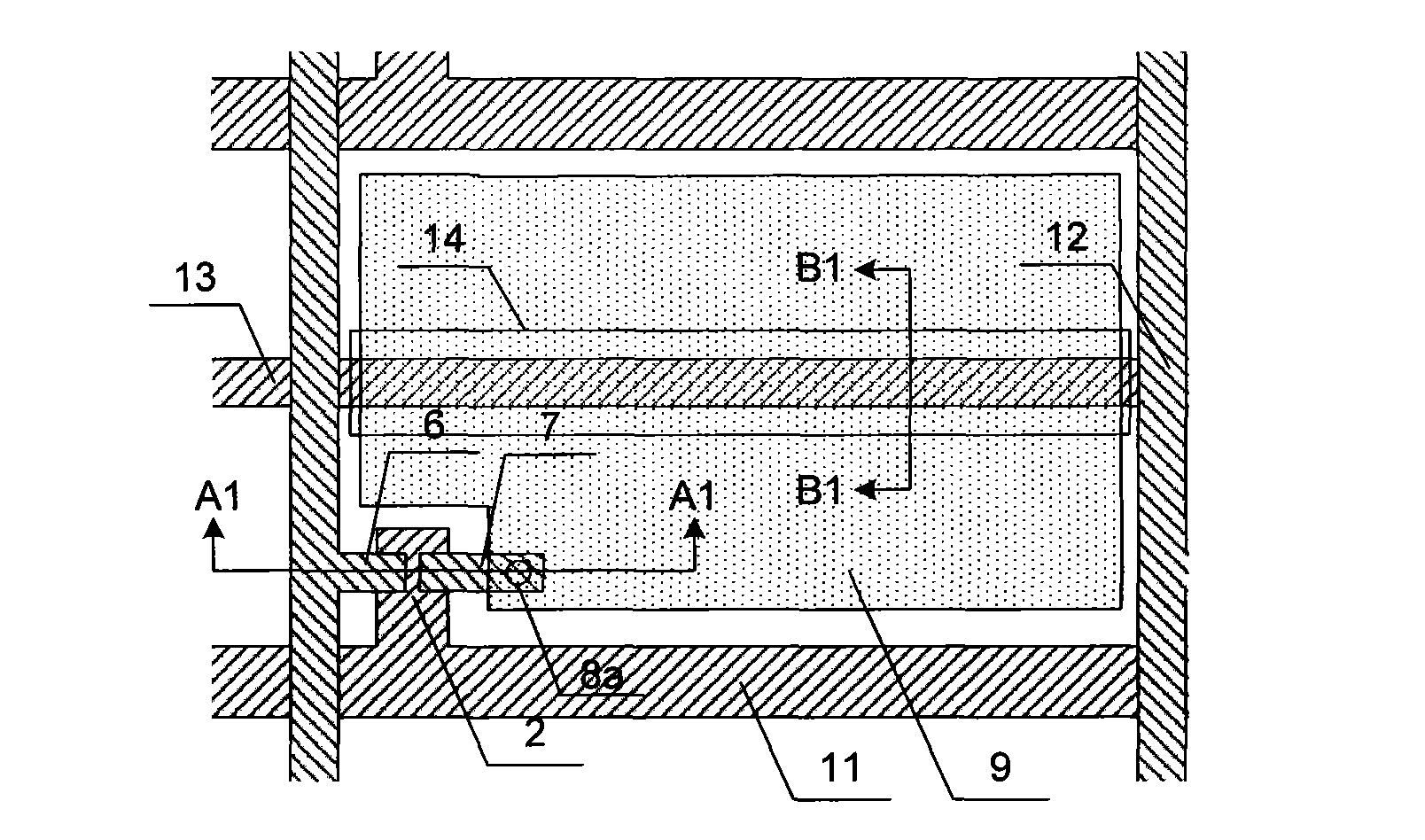

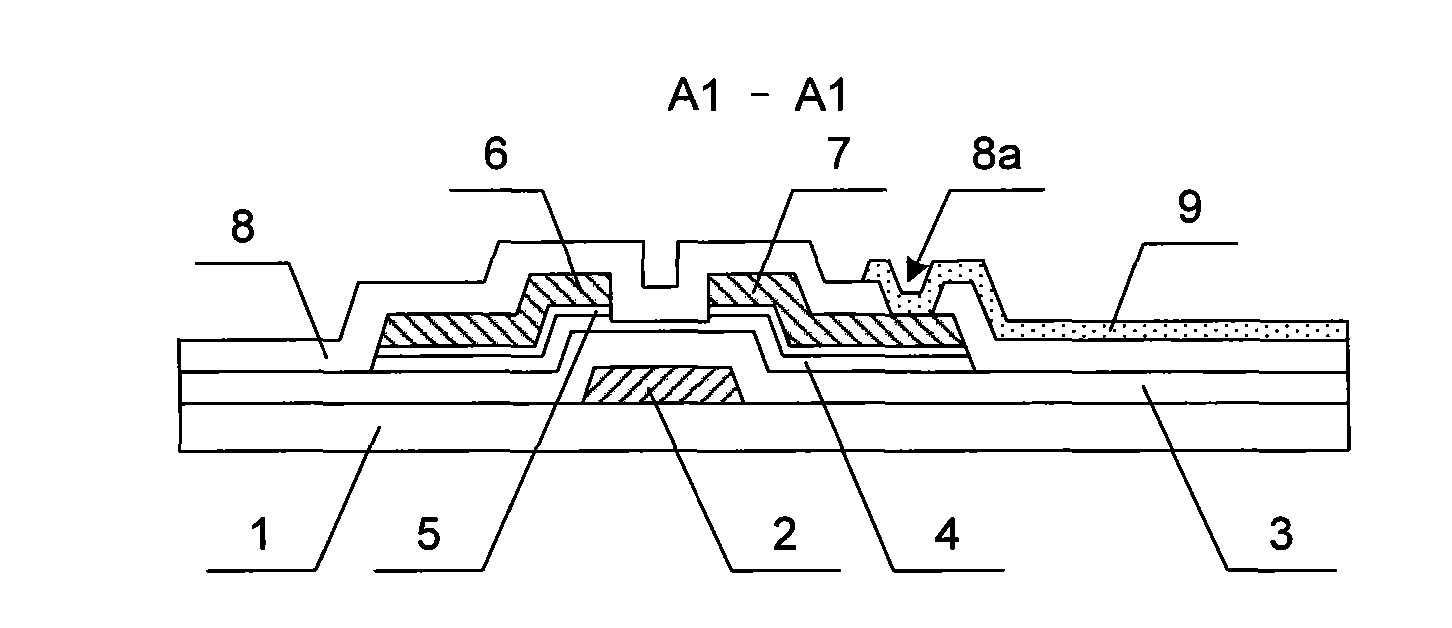

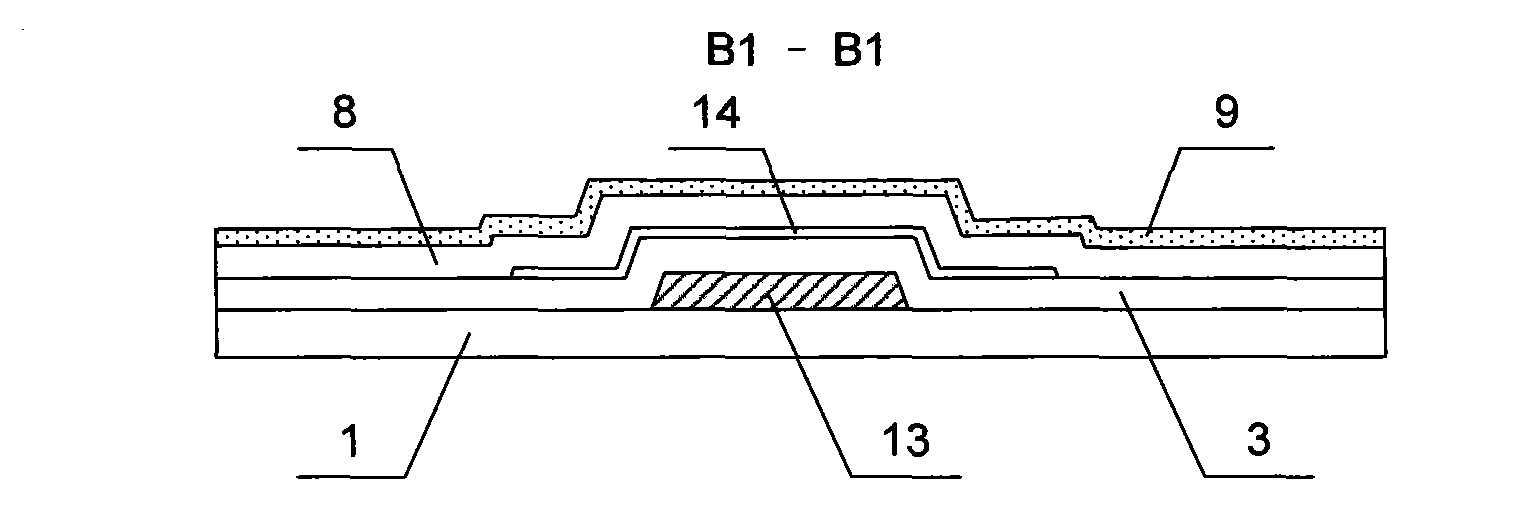

[0063] figure 1 It is a plan view of the first embodiment of the TFT-LCD array substrate of the present invention, reflecting the structure of a pixel unit, figure 2 for figure 1 The cross-sectional view of A1-A1 in the middle, image 3 for figure 1 Sectional view of B1-B1 direction in the middle. Such as Figure 1 ~ Figure 3 As shown, the TFT-LCD array substrate of this embodiment is a structure formed by four patterning processes. The main structure includes gate lines 11, data lines 12, common electrode lines 13, pixel electrodes 9 and thin film formed on the substrate 1. Transistors, gate lines 11 and data lines 12 perpendicular to each other define a pixel area, thin film transistors and pixel electrodes 9 are formed in the pixel area, gate lines 11 are used to provide turn-on signals to the thin film transi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com