CMP slurry and a polishing method using the same

一种浆料、抛光磨的技术,应用在化学仪器和方法、含研磨剂的抛光组合物、电气元件等方向,能够解决凹陷、器件性质劣化、器件性能和可靠性不利影响等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

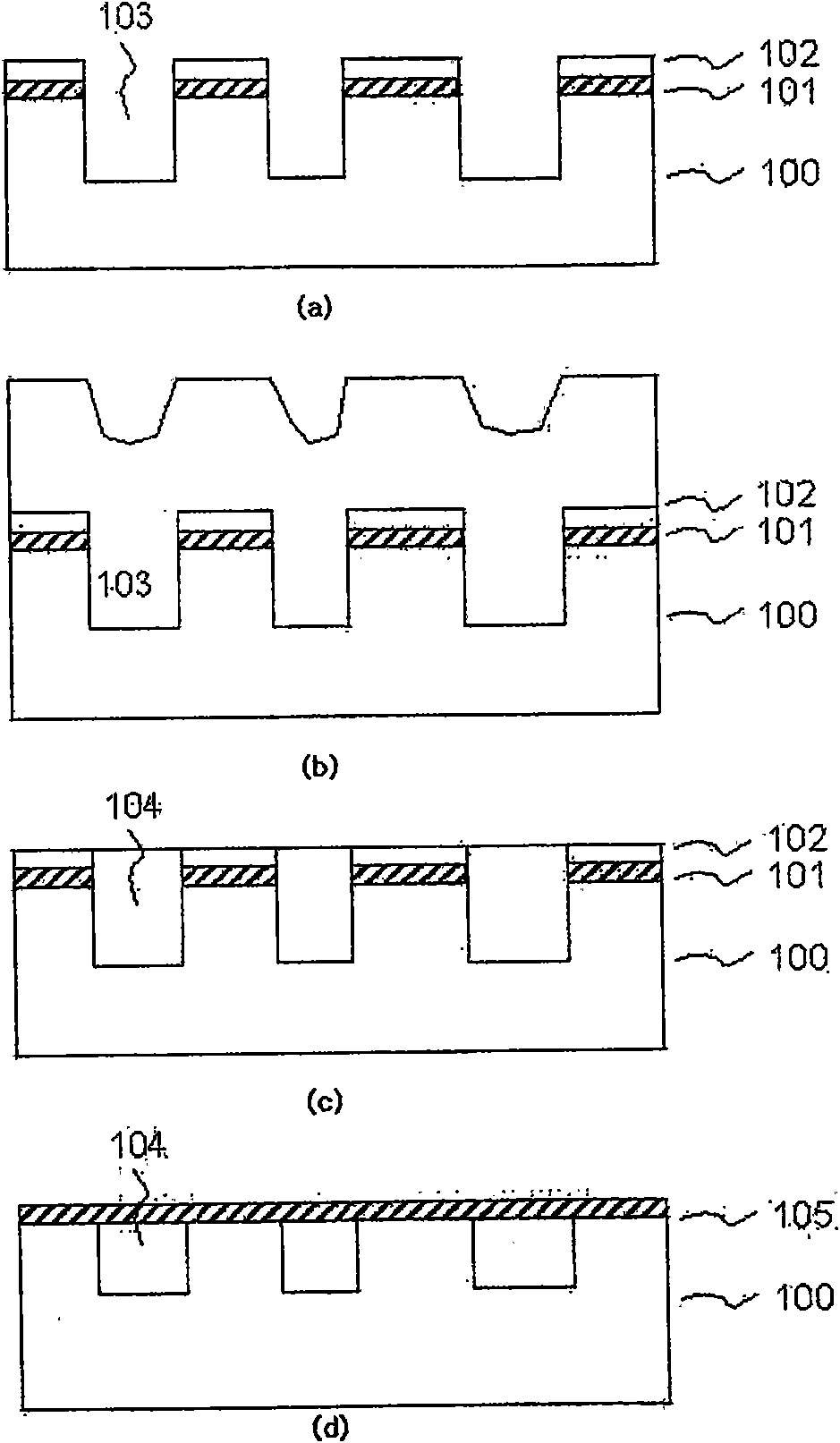

Method used

Image

Examples

Embodiment 1

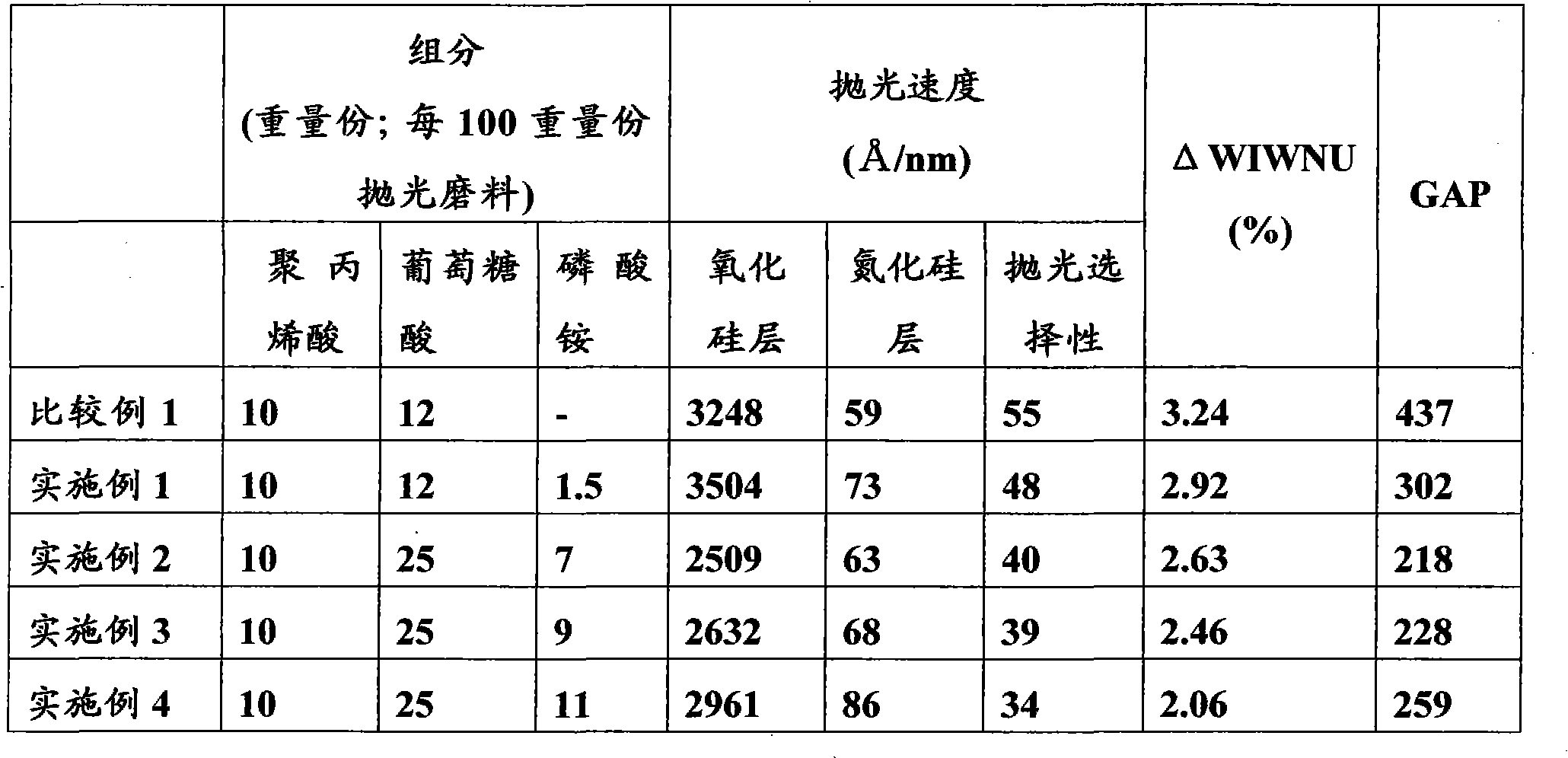

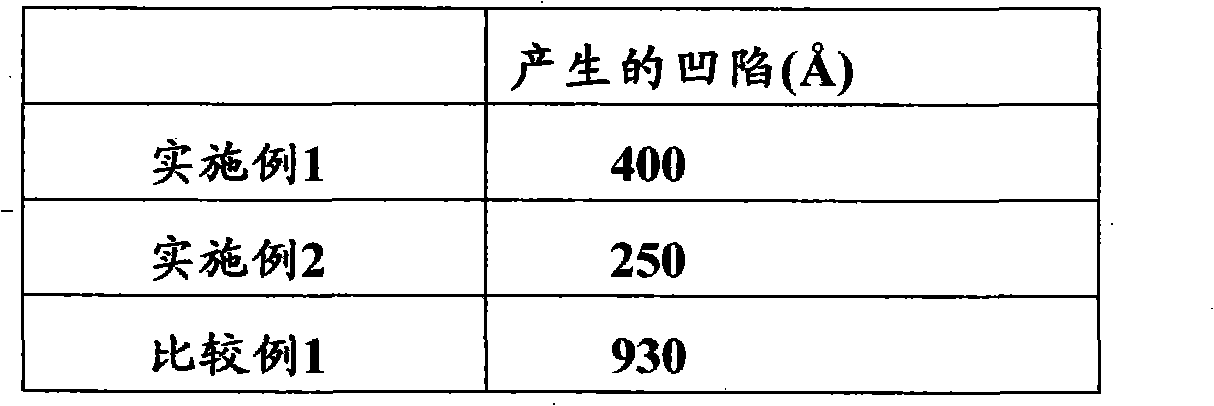

[0058] By combining cerium oxide as a polishing abrasive, polyacrylic acid (Mw.: 7,000) as a linear anionic polymer, gluconic acid as a compound containing hydroxyl and / or carboxyl groups, and ammonium phosphate ((NH 4 ) 2 HPO 4 ) was added to pure water and mixed to prepare a CMP slurry.

[0059] Here, 5 parts by weight of polishing abrasive is added per 100 parts by weight of CMP slurry, 10 parts by weight of linear anionic polymer is added for every 100 parts by weight of cerium oxide polishing abrasive, and 25 parts by weight is added for every 100 parts by weight of cerium oxide polishing abrasive. 1.5 parts by weight of compound containing hydroxyl group and / or carboxyl group, and 1.5 parts by weight of compound containing phosphoric acid group for every 100 parts by weight of cerium oxide polishing abrasive.

Embodiment 2-4

[0061] The CMP slurry was prepared in substantially the same manner as in Example 1, except that the content of compounds containing hydroxyl and / or carboxyl groups and the content of compounds containing phosphoric acid groups were changed as shown in Table 1 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight-average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com