Method and apparatus for purifying argon, and method and apparatus for purifying object gas

A refining method and refining device technology, applied in the direction of separation methods, inert gas compounds, chemical instruments and methods, etc., can solve problems such as taking a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

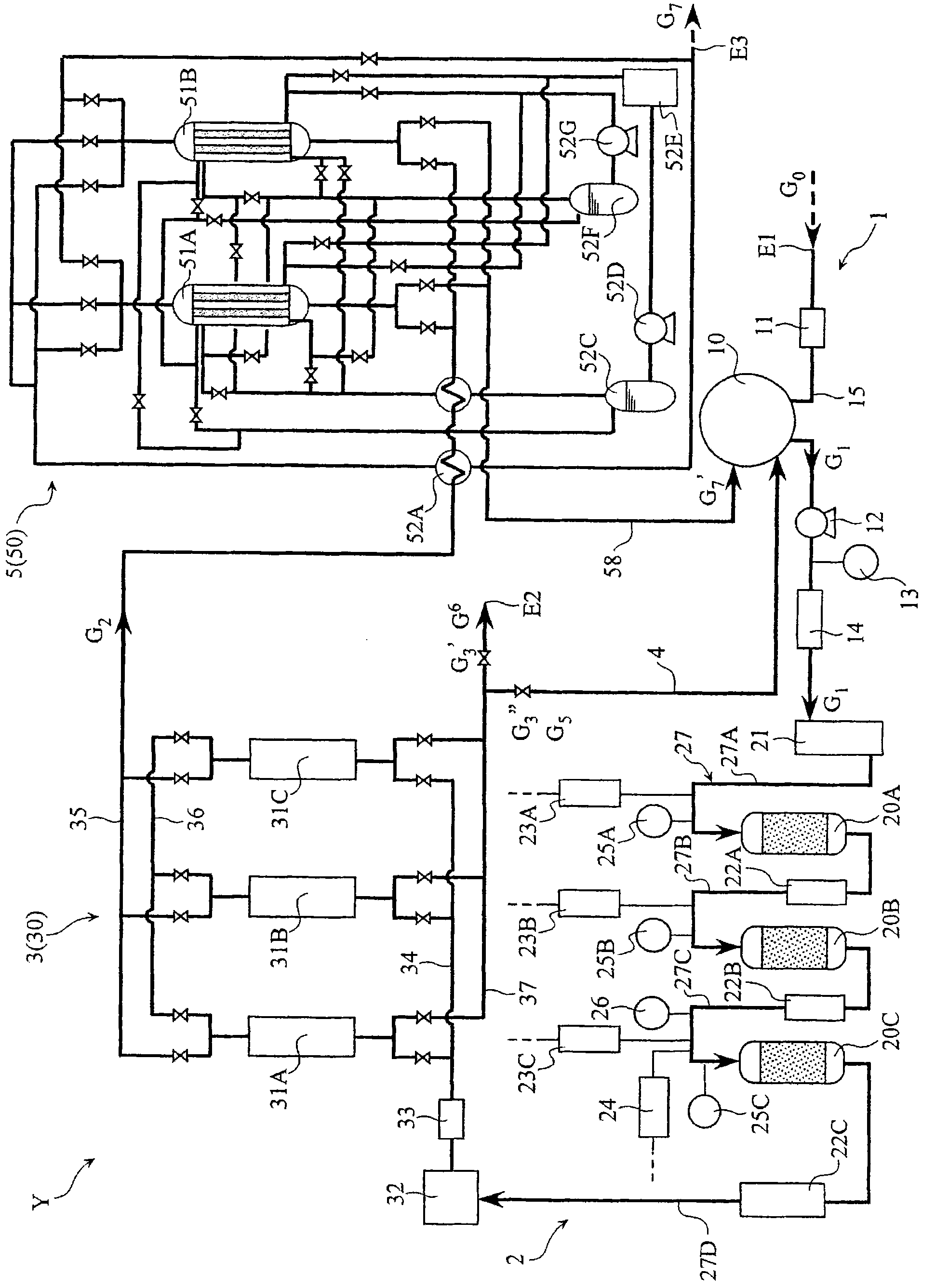

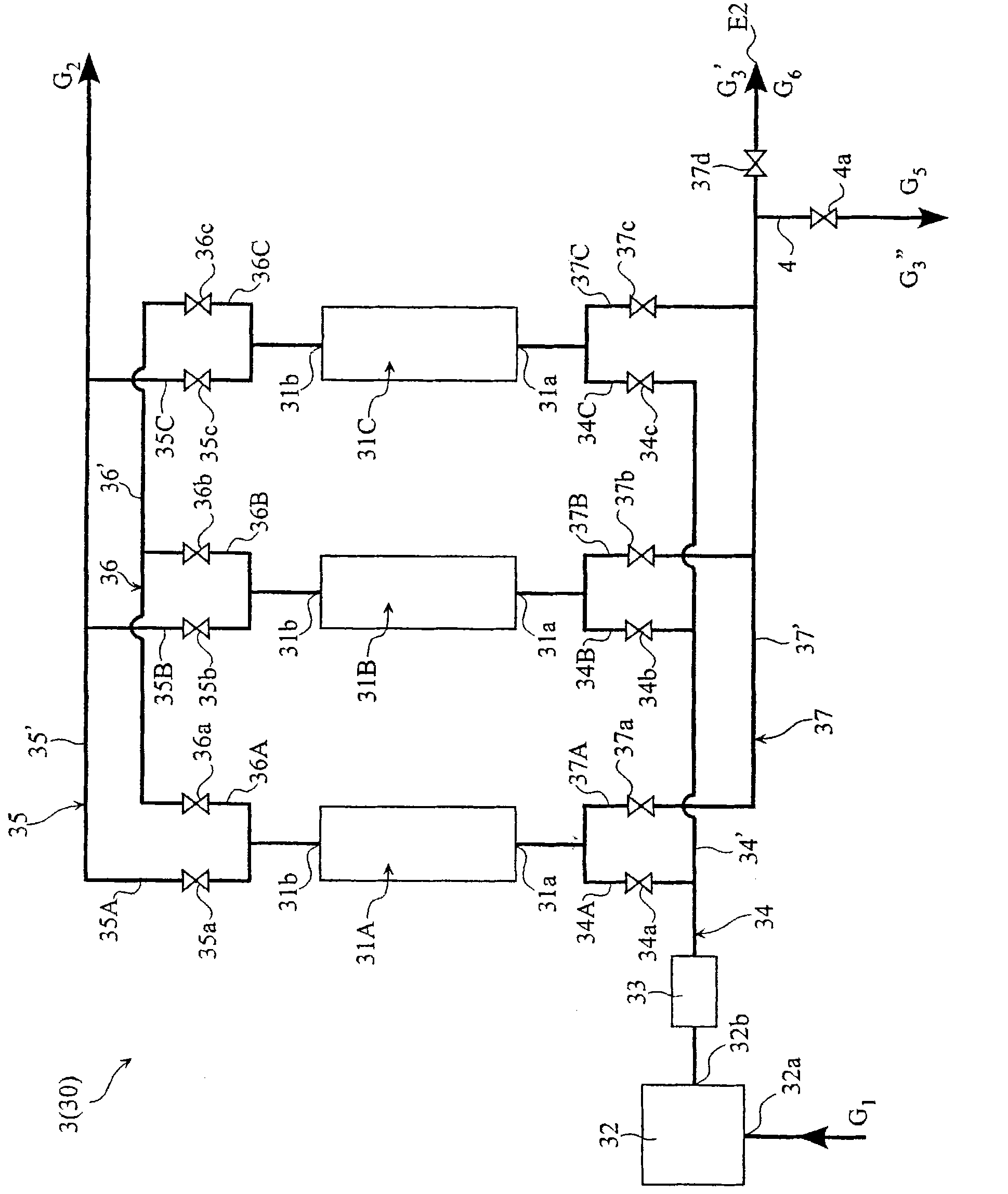

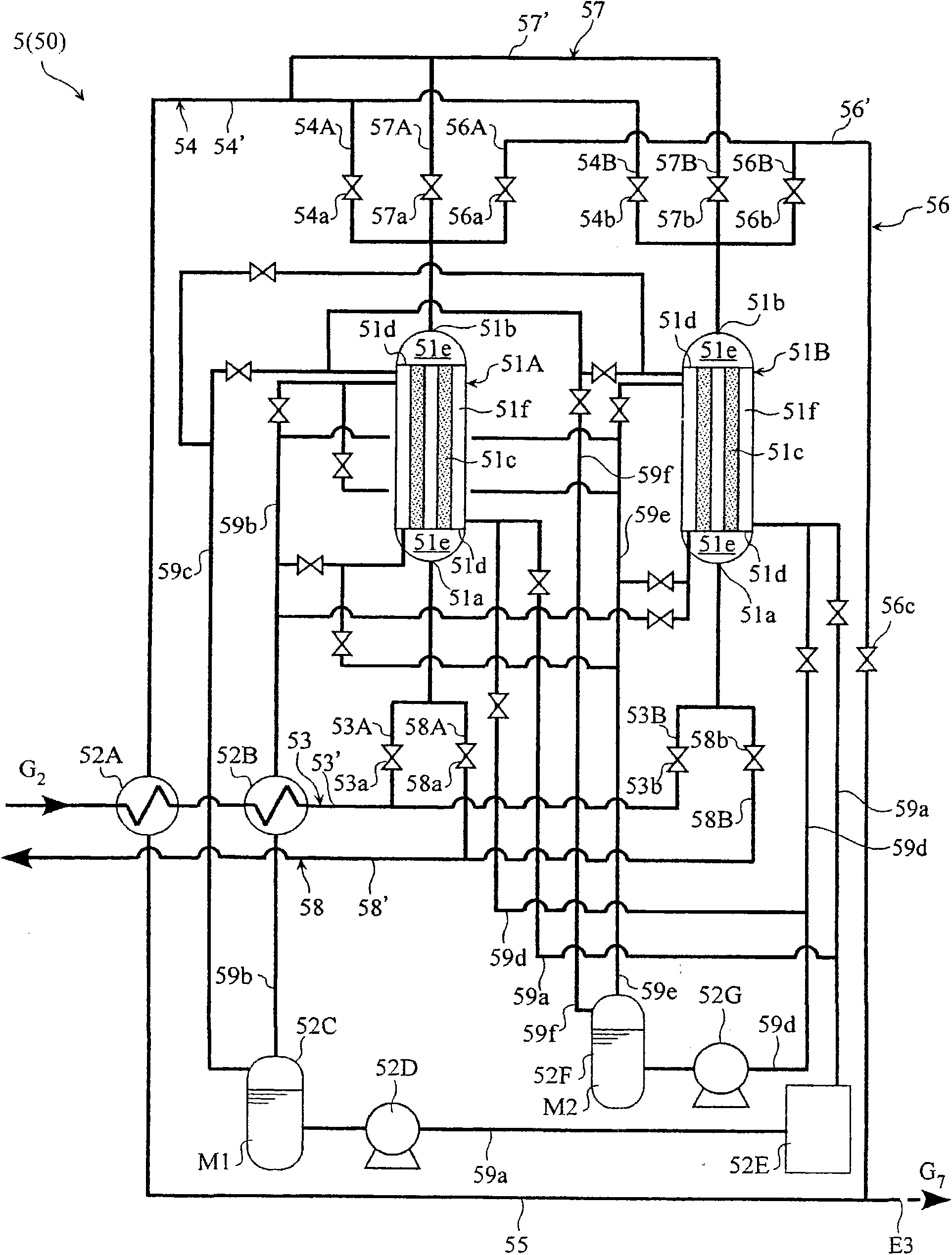

[0148] use Figure 1 ~ Figure 3 The argon refining device Y shown, from the specified raw material gas G 0 The argon was concentrated and separated. The raw material gas G of this embodiment 0It is used atmospheric gas discharged from a silicon single crystal pulling furnace, and contains argon as a main component. The raw gas G 0 The specifications are documented in Figure 22 in the table.

[0149] In this embodiment, in the storage system 1, the raw material gas G is input to the buffer tank 10 0 , and the gas G is continuously supplied from the buffer tank 10 to the rear stage (pretreatment system 2, PSA system 3) 1 . About Gas G 1 , through the booster blower 12 and the flow control unit 14, the pressure is set to 0.1MPa, and the flow is controlled to 20Nm 3 / h.

[0150] In this embodiment, in the pretreatment system 2, the gas G is treated under the following conditions 1 Pre-processing was carried out. As the catalyst in the pretreatment tank 20A, a platinum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com