External anaerobic ammonia oxidation membrane bioreactor

A technology of membrane bioreactor and anaerobic ammonium oxidation, which is applied in the direction of anaerobic digestion and treatment, can solve the problems of unfavorable living environment for anaerobic ammonium bacteria and sludge loss, and achieve the effect of avoiding sludge loss and efficient denitrification , to ensure the effect of anaerobic environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

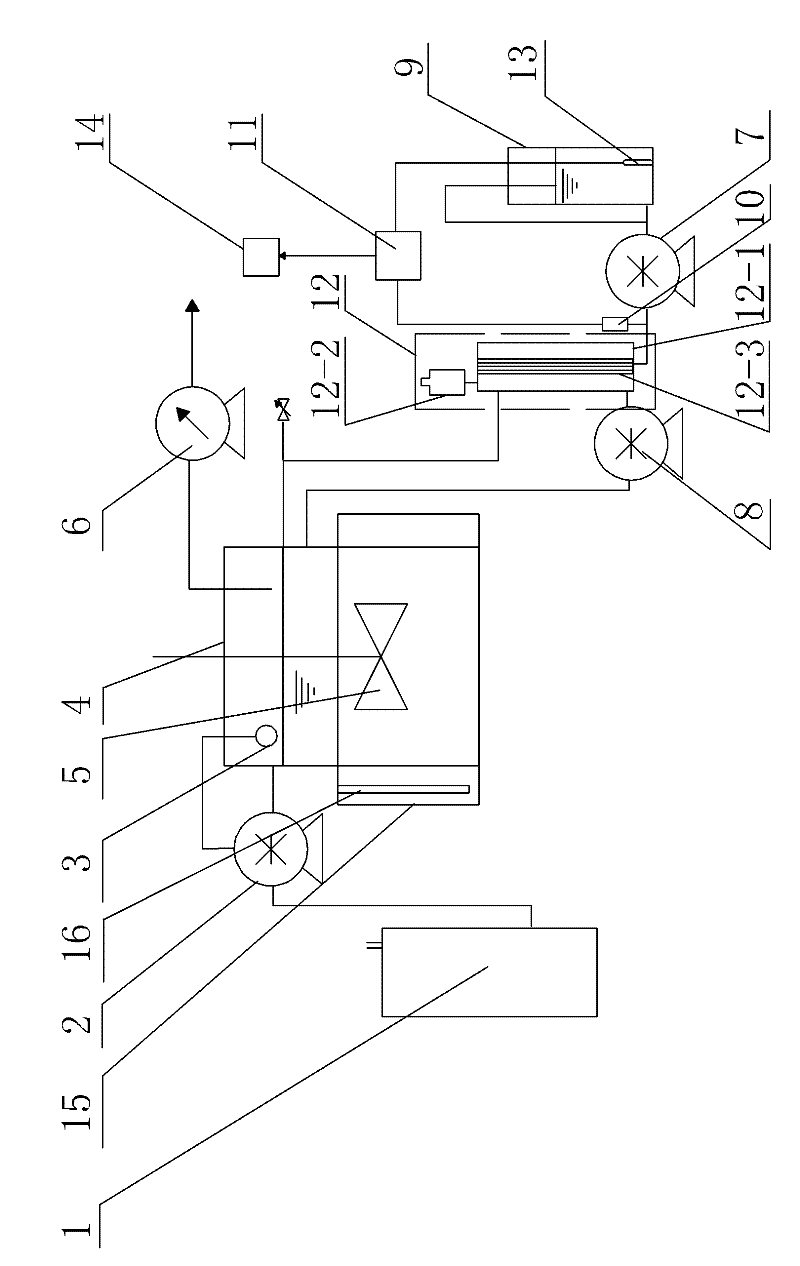

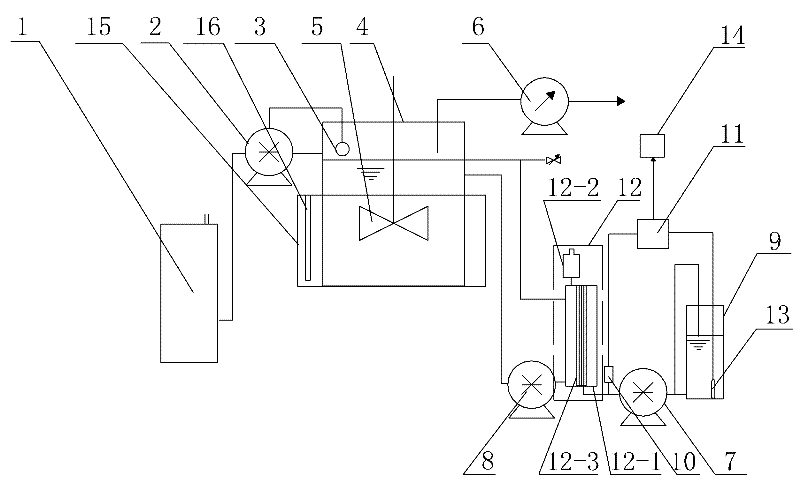

[0010] Specific implementation mode one: combine figure 1 Describe this embodiment, the bioreactor of this embodiment includes water inlet tank 1, water inlet pump 2, electronic float valve 3, anaerobic tank 4, stirring paddle 5, wet gas flow meter 6, water outlet pump 7, reflux pump 8, Water outlet cylinder 9, pressure sensor 10, data acquisition module 11, membrane assembly 12 and liquid level gauge 13, membrane assembly 12 is composed of cylindrical plexiglass cylinder 12-1, air pressure balance tube 12-2 and multiple membrane wires 12-3 , the top of the plexiglass cylinder 12-1 is provided with an air pressure balance tube 12-2, a plurality of membrane filaments 12-3 are arranged in the plexiglass cylinder 12-1 along the direction of the central axis, the inlet end of the water inlet tank 1 and the water inlet pump 2 connected, the water inlet pump 2 is electrically connected with the electronic float valve 3, the electronic float valve 3 is set in the anaerobic tank 4, t...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination figure 1 To illustrate this embodiment, the lower end of the pressure sensor 10 in this embodiment is higher than the water outlet end of each membrane filament 12-3, and the difference between the two is 2-3 cm. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0013] Specific implementation mode three: combination figure 1 Describe this embodiment, the bioreactor of this embodiment also comprises water bath container 15 and temperature control rod 16, and anaerobic tank 4 is arranged in water bath container 15, is provided with temperature control rod 16 in water bath container 15, and this structure guarantees anaerobic The temperature in tank 4 was maintained at 35°C. Other components and connections are the same as those in the first embodiment.

[0014] Working principle: The sewage in the water inlet tank 1 is continuously pumped into the anaerobic tank 4 by the water inlet pump 2. When the water level in the anaerobic tank reaches a certain value, the electronic float valve 3 rises, and the water inlet pump 2 is turned off to avoid excessive liquid level. The high temperature causes sludge loss; the anaerobic ammonium oxidizing bacteria are arranged in the anaerobic tank 4, and the stirring paddle 5 fully mixes the sewage in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com