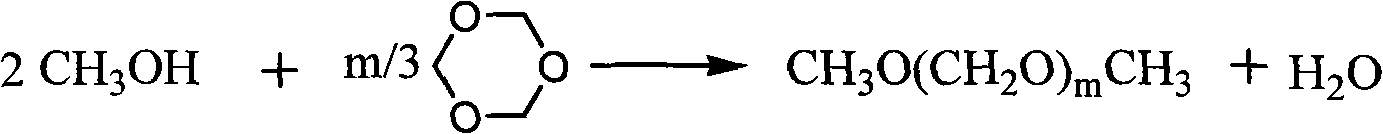

Method for synthesizing polymethoxy dimethyl ether under catalysis of geminal dicationic ionic liquid

A polymethoxydimethyl ether, ionic liquid technology, applied in chemical instruments and methods, preparation of organic compounds, catalysts for physical/chemical processes, etc., can solve the problem that the selectivity of chemical reactions is difficult to control, frequent regeneration, shortening catalyst Life and other issues, to achieve the effect of easy operation, mild reaction conditions and low corrosiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

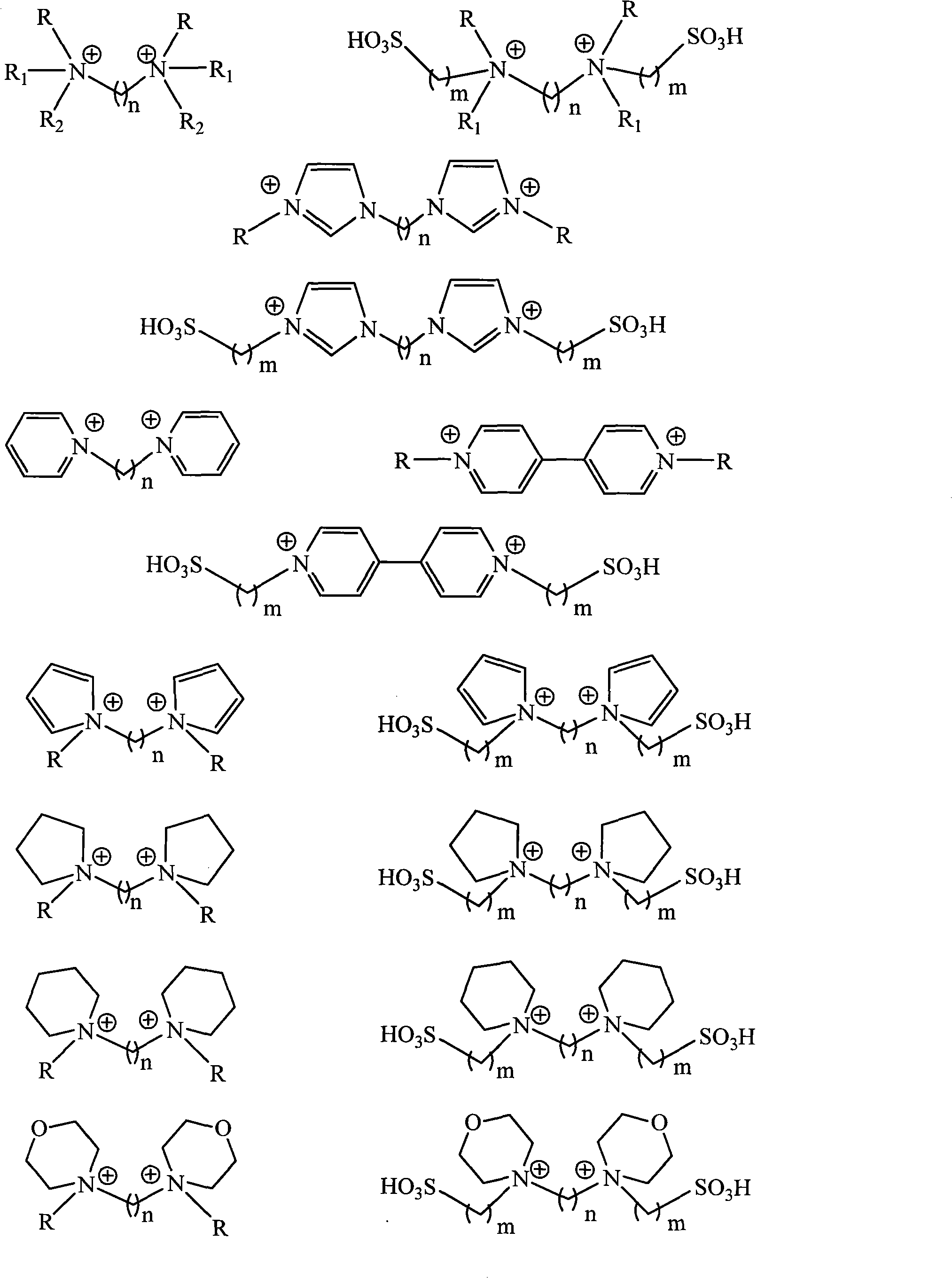

Method used

Image

Examples

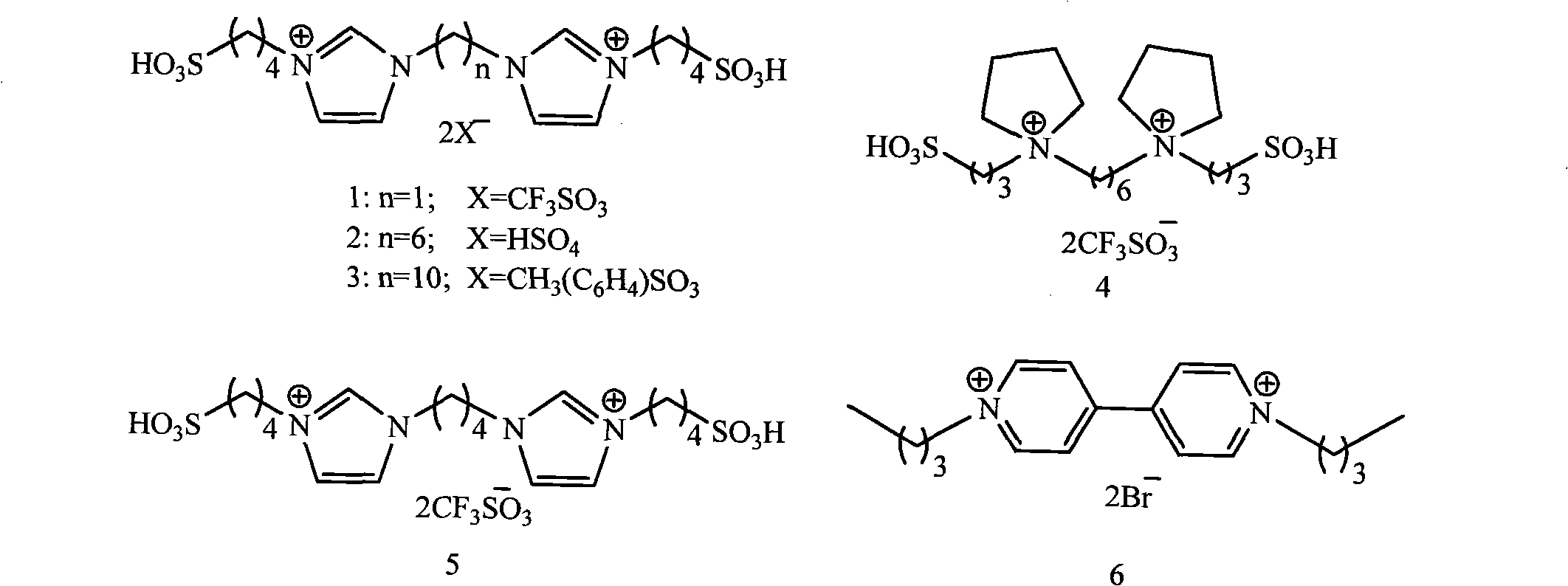

Embodiment 1

[0030] In a 100mL reactor, add 0.202g of catalyst 1, 3.982g of methanol, and 5.572g of paraformaldehyde in sequence. Inflate nitrogen to a pressure of 2.7 MPa, heat to 353K and stir for 4 hours. According to gas chromatography analysis, the conversion rate of paraformaldehyde is 85.4%. The relative content is methylal (m=1), 50.1%; m=2, 32.3%; m =3-8, 17.6%; m>8, not detected.

Embodiment 2

[0032] As in Example 1, 0.156g of catalyst 2, 6.441g of methanol, and 10.213g of paraformaldehyde were added in sequence. Inflate with nitrogen to a pressure of 3.0MPa, heat to 423K and stir for 1 hour. According to gas chromatography analysis, the conversion rate of paraformaldehyde is 57.5%. The relative content is methylal (m=1), 30.9%; m=2, 26.6%; m=3~8, 41.4%; m>8, 1.1%.

Embodiment 3

[0034] As in Example 1, 0.091 g of catalyst 3, 3.474 g of methanol, and 7.237 g of paraformaldehyde were added in sequence. Inflate with nitrogen to a pressure of 2.2 MPa, heat to 393K and stir for 6 hours. According to gas chromatography analysis, the conversion rate of paraformaldehyde is 91.2%. The relative content is methylal (m=1), 24.9%; m=2, 41.9%; m=3~8, 33.2%; m>8, not detected.

PUM

| Property | Measurement | Unit |

|---|---|---|

| corrosion rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com