Wood fiber water-absorbent material and preparation method thereof

A water-absorbing material and wood fiber technology, which is applied in the field of materials, can solve problems such as restricting the development of water-absorbing materials, and achieve the effect of practical industrial promotion value, good water absorption and water retention performance, and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

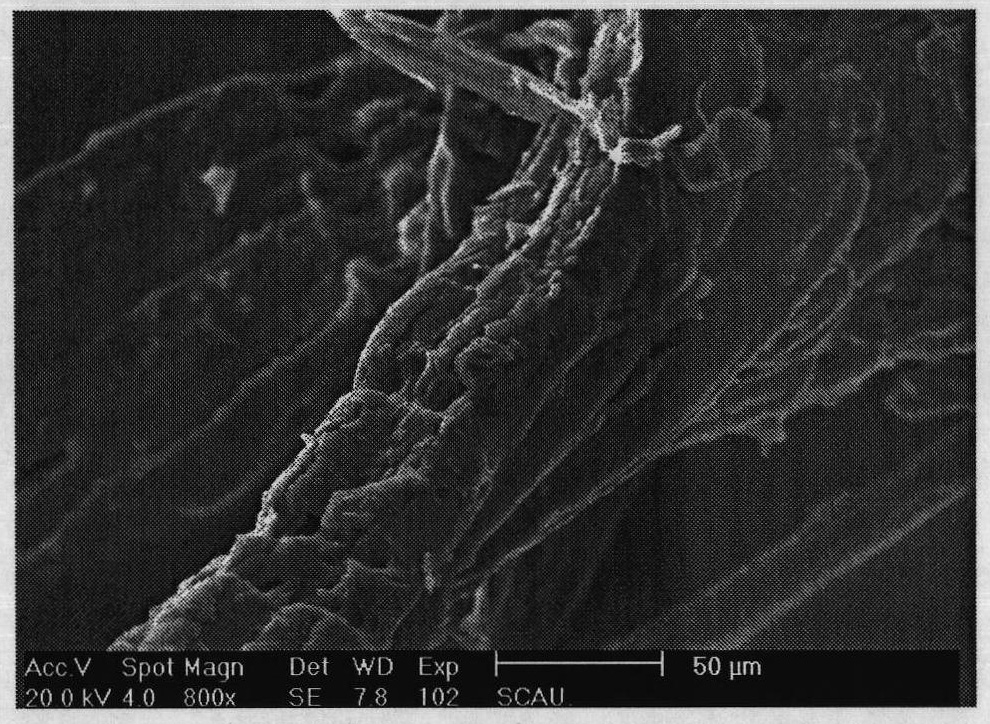

Image

Examples

Embodiment 1

[0029] Mix 45-mesh wood fiber and water according to the mass ratio of 1:100, boil for 3 hours, then suction filter and wash with water, repeat this step 3 times, and dry the wood fiber after this process until it is absolutely dry to obtain absolute dry wood fiber. fiber.

[0030] Boil the above-mentioned dry wood fiber with water with a bath ratio of 1:100 for 2 hours and then dry it, then mix the activation treatment agent with liquid ammonia-acetone, stir and replace 3 times at a bath ratio of 1:2, and dry to dryness;

[0031] Mix according to the mass ratio of dry wood fiber and water as 1:100, and add acrylic acid (AA) according to the mass ratio of dry wood fiber to acrylic acid (AA) monomer as 1:7 at a temperature of 65°C under nitrogen protection monomer, and then add the initiator KMnO successively 4 and H 2 SO 4 , so that KMnO 4 Concentration reaches 15mmol / L, H 2 SO 4 The concentration reached 18mmol / L, stirred and reacted for 240 minutes, washed with water a...

Embodiment 2

[0033] Mix 45-mesh wood fiber and water according to the mass ratio of 1:100, boil for 3 hours, then suction filter and wash with water, repeat this step 3 times, and dry the wood fiber after this process until it is absolutely dry to obtain absolute dry wood fiber. fiber.

[0034] Boil the above-mentioned absolute dry wood fiber with water with a bath ratio of 1:100 for 2 hours and then dry it, then use a NaOH solution with a mass concentration of 20% at a bath ratio of 1:50 at a temperature of 68±1°C for 2 hours to activate , dried to absolute dryness;

[0035] Mix according to the mass ratio of dry wood fiber and water as 1:100, and add acrylic acid (AA) according to the mass ratio of dry wood fiber to acrylic acid (AA) monomer as 1:7 at a temperature of 65°C under nitrogen protection monomer, and then add the initiator KMnO successively 4 and H 2 SO 4 , so that KMnO 4 Concentration reaches 15mmol / L, H 2 SO 4 The concentration reached 18mmol / L, stirred and reacted fo...

Embodiment 3

[0037] Mix 45-mesh wood fiber and water according to the mass ratio of 1:100, boil for 3 hours, then suction filter and wash with water, repeat this step 3 times, and dry the wood fiber after this process until it is absolutely dry to obtain absolute dry wood fiber. fiber.

[0038] Mix according to the mass ratio of dry wood fiber and water as 1:100, and add acrylic acid (AA) according to the mass ratio of dry wood fiber to acrylic acid (AA) monomer as 1:5 at a temperature of 65°C under the protection of nitrogen monomer, and then add the initiator KMnO successively 4 and H 2 SO 4 , so that KMnO 4 Concentration reaches 20mmol / L, H 2 SO 4When the concentration reaches 20mmol / L, stir and react for 240 minutes, wash with water and dry to absolute dryness to obtain the lignocellulosic water-absorbing material (ie graft-copolymerized polyacrylic acid lignocellulosic water-absorbing material). The polymer content was 27.58%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com