Three-dimensional fluorescence nano microscope imaging method and system, and image equipment

A three-dimensional fluorescence and microscopic imaging technology, applied in fluorescence/phosphorescence, material excitation analysis, etc., can solve the problems of difficult sample observation and low molecular positioning accuracy, improve lateral and axial positioning accuracy, and achieve axial selectivity Easy to stimulate and observe the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

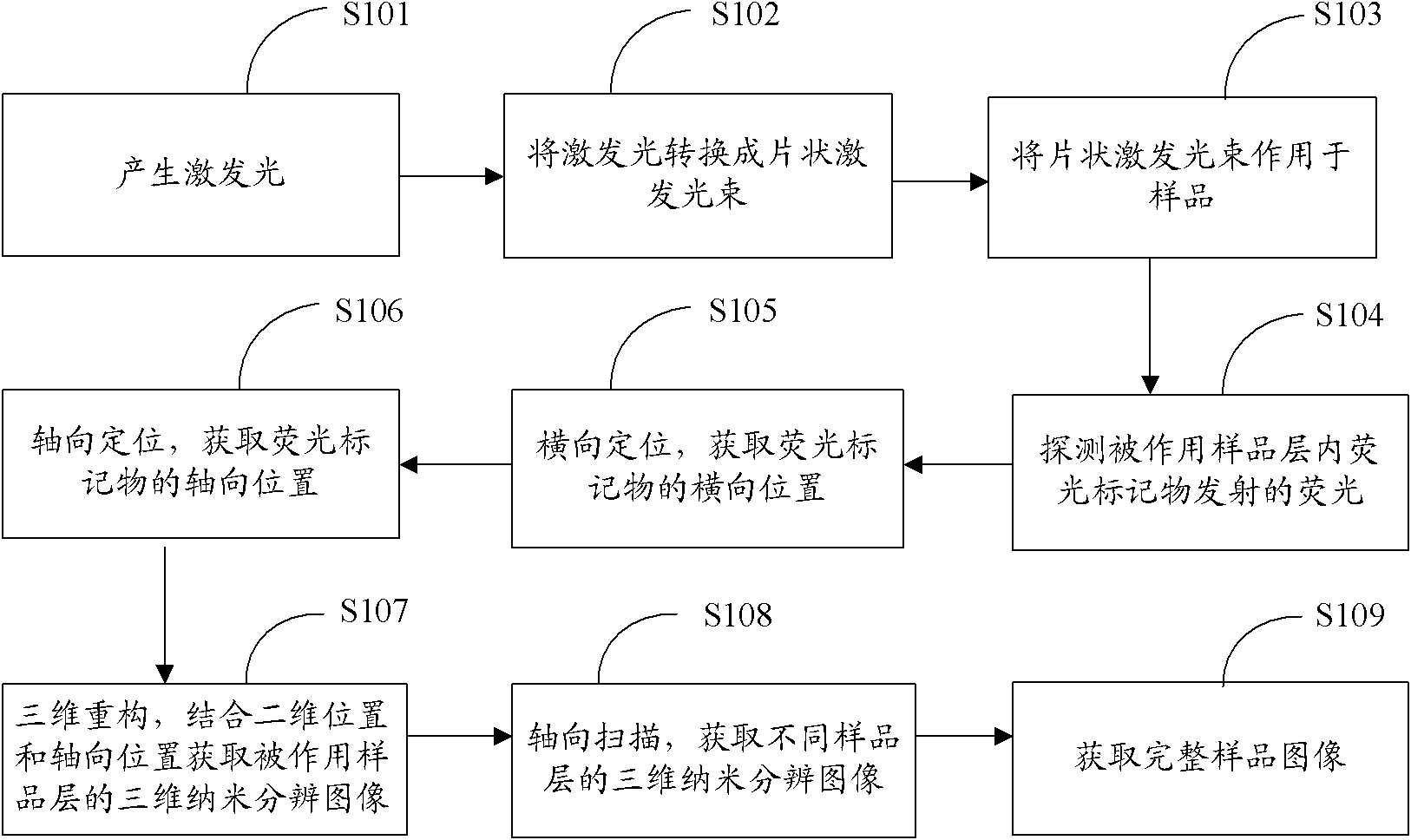

[0051] figure 1 The implementation process of the three-dimensional fluorescence nanomicroscopic imaging method provided by the first embodiment of the present invention is shown, and the details are as follows:

[0052] In step S101, generating excitation light;

[0053] In step S102, converting the excitation light into a sheet-shaped excitation beam;

[0054] In step S103, applying a sheet-shaped excitation beam to the sample;

[0055] In step S104, detecting the fluorescence emitted by the fluorescent marker in the sample layer;

[0056] In step S105, horizontal positioning is used to obtain the two-dimensional position of the fluorescent marker;

[0057] In step S106, axial positioning, obtaining the axial position of the fluorescent marker;

[0058] In step S107, three-dimensional reconstruction, combining the two-dimensional position and axial position to obtain a three-dimensional nano-resolution image of the applied sample layer;

[0059] In step S108, scan axial...

Embodiment 2

[0062] In the embodiment of the present invention, the excitation light should be able to achieve sparse excitation of the fluorescent marker, and its wavelength should be selected from the excitation spectrum of the fluorescent marker with stronger excitation. The light source of the excitation light can choose a laser light source with better monochromaticity.

Embodiment 3

[0064] In the embodiment of the present invention, the sheet-shaped excitation light beam can be obtained by the following method: After the excitation light generated by the light source is collimated and expanded, the sheet-shaped beam is formed by the sheet-shaped beam acquisition element; The depth of focus of the sheet-like beam, the thickness of the sheet-like beam with a large depth of focus passing through the illumination objective lens is greatly reduced, so that the beam is approximately an ultra-thin sheet-like parallel beam within the focal depth range.

[0065] As an embodiment of the present invention, the order of magnitude of the depth of focus of the sheet-like excitation beam is higher than the order of magnitude of the radial length of the applied sample layer in the direction of the excitation light path, and the thickness of the sheet-like excitation beam is less than 1 micron.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com