Control system of glass steel container winding machine and control method thereof

A control method and technology of a control system, which are applied in the field of glass fiber reinforced plastic container manufacturing in the chemical industry, can solve the problems of inaccurate return line, winding line shape, low production efficiency, etc., so as to solve the complex structure of the control system, reduce the cost of self-weight transportation, and reduce energy. The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

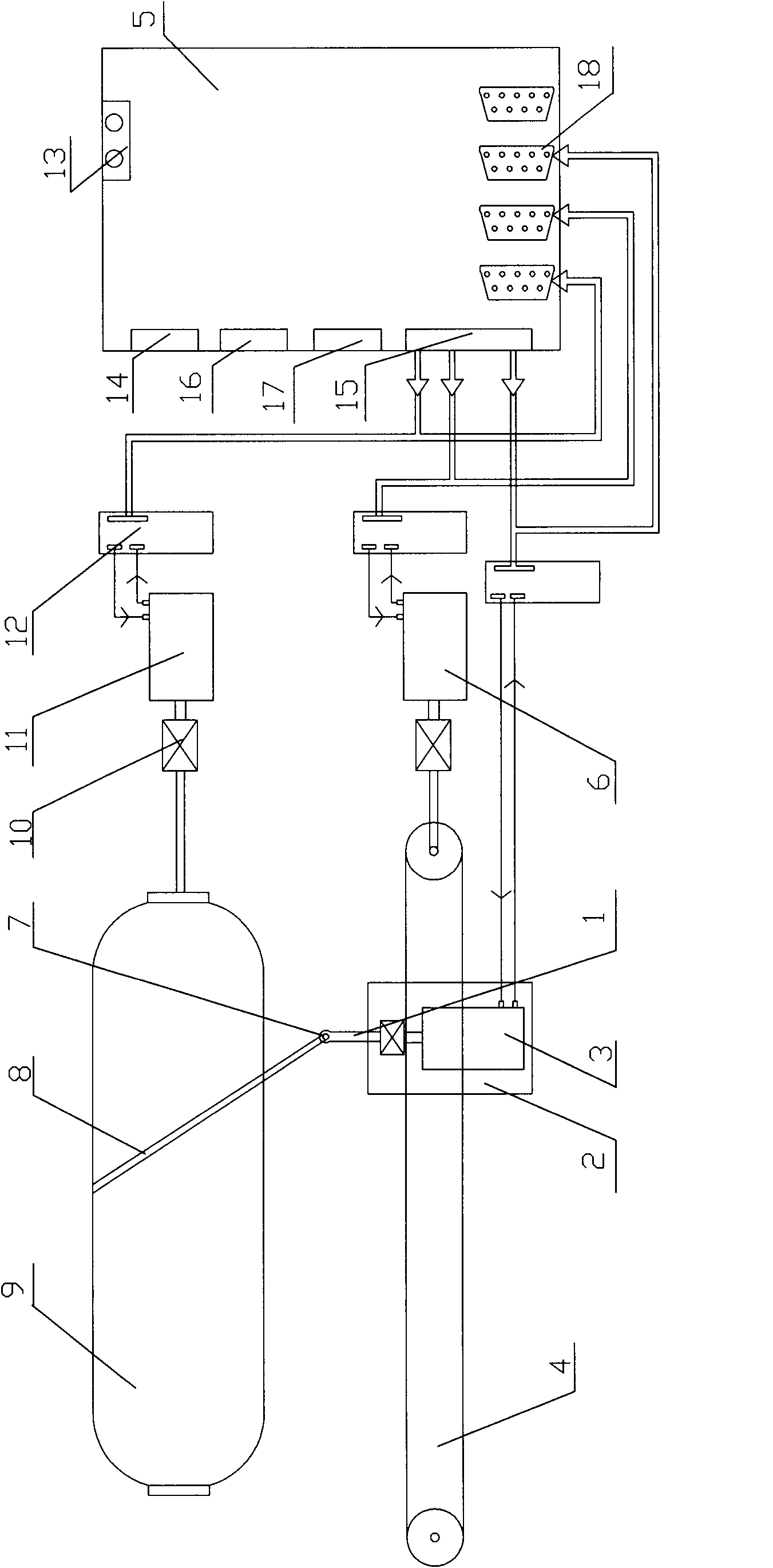

[0019] A glass fiber reinforced plastic container winding machine control system, which consists of: a trolley 2 with an outrigger 1, the trolley 2 is connected to the outrigger servo motor 3, the bottom of the trolley 2 is connected to the trolley track 4, and the outrigger servo The motor 3 is connected to the motion controller TRIO5, the trolley track 4 is connected to the motion controller TRIO5 through the trolley servo motor 6, the outrigger 1 is connected to the fiber 8 through the wire nozzle 7, and the fiber 8 is connected to the spindle mandrel 9, The spindle mandrel 9 is connected to a spindle servo motor 11 through a reducer 10 , and the spindle servo motor 11 is connected to a motion controller TRIO5 through a servo driver 12 .

[0020] In the control system of the glass fiber reinforced plastic container winding machine, the motion controller TRIO5 includes a serial communication port 13 installed on the upper end, and a power module 14, an input module 15, and an...

Embodiment 2

[0022] A control method for a glass fiber reinforced plastic container winding machine. The motion controller controls the speed of the main shaft in the form of an analog quantity, drives the main shaft motor to drive the mandrel to rotate, and at the same time adopts an electronic cam method based on the control algorithm PID (proportional -integral-differential) to realize the motion control of the trolley and the outrigger motor synchronously tracking the main shaft; the motion controller adopts the servo axis mode to realize the closed-loop control of the trolley and the outrigger servo system; finally, the three-axis coordinated movement of the winding machine is simplified to the car tracking the main shaft The single-axis servo motion and the single-axis servo motion of the outrigger tracking spindle realize the precise motion control of the yarn nozzle winding along the geodesic line of the container to ensure good lapping of the yarn pieces.

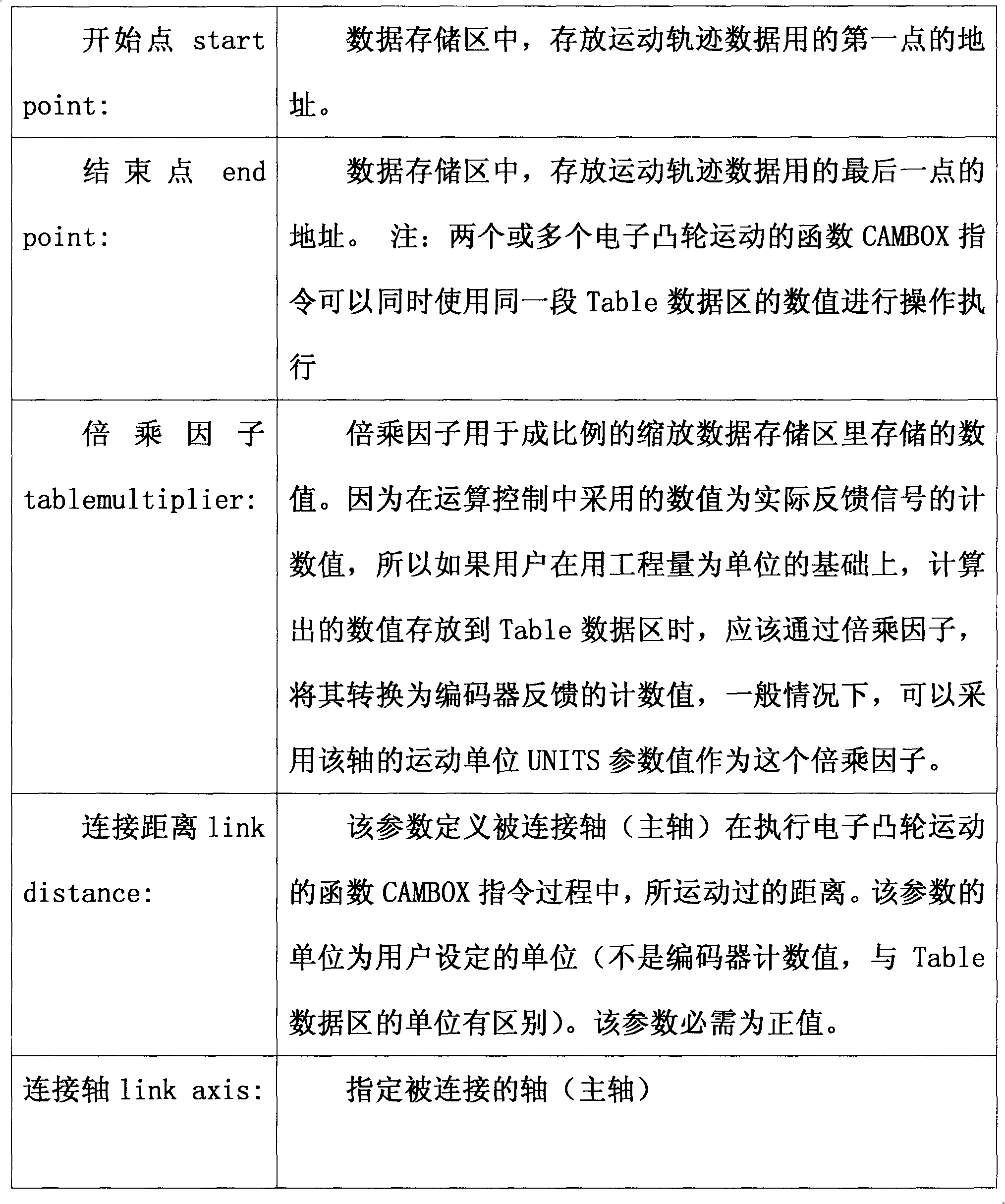

[0023] In the control me...

Embodiment 3

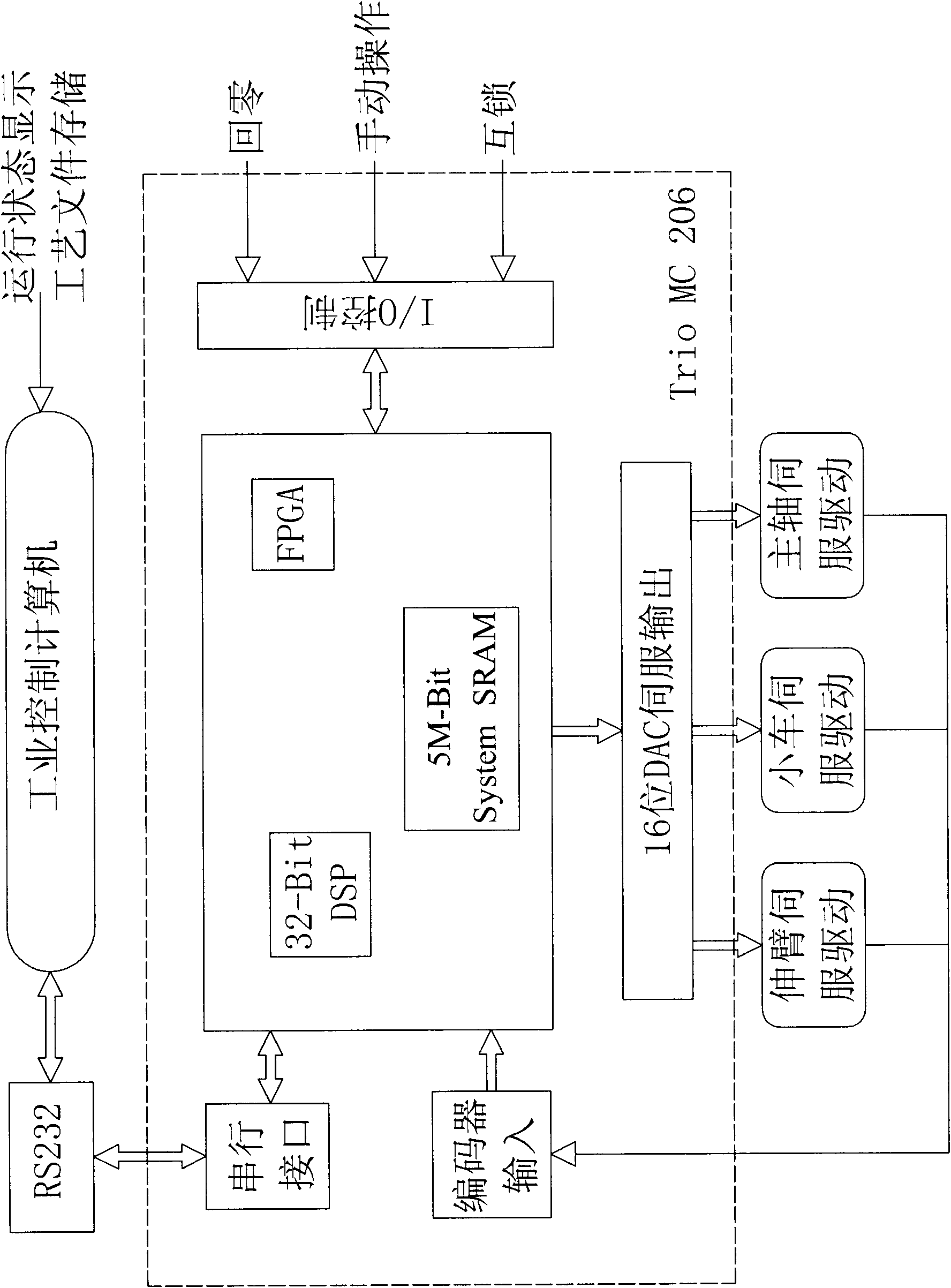

[0026] In the control system and control method of the glass fiber reinforced plastic container winding machine described in Embodiment 1 or 2, the upper industrial computer of the glass fiber reinforced plastic container winding machine control system mainly completes functions such as motion state display, man-machine interface management, process file storage, error diagnosis and remote monitoring. The lower computer adopts the motion controller model MC206 embedded motion controller from Trio Motion Technology Company, which is mainly responsible for real-time motion control and logic control, including speed, acceleration and deceleration, position, multi-axis interpolation, and stroke control. Real-time servo updates and other digital input / digital output I / O control. The upper and lower computers communicate through the serial port based on the network communication protocol MODBUS communication protocol, complete the transmission of process parameters and upload and dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com