Wireless stress tester of hydro-power generating unit

A technology of hydroelectric unit and tester, which is applied in the direction of applying repeated force/pulsation force to test the strength of materials, instruments, and measuring force, which can solve the problems of strong danger, inconvenient wiring, and low work efficiency, and reduce the difficulty of operation , Simplify maintenance work, improve test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

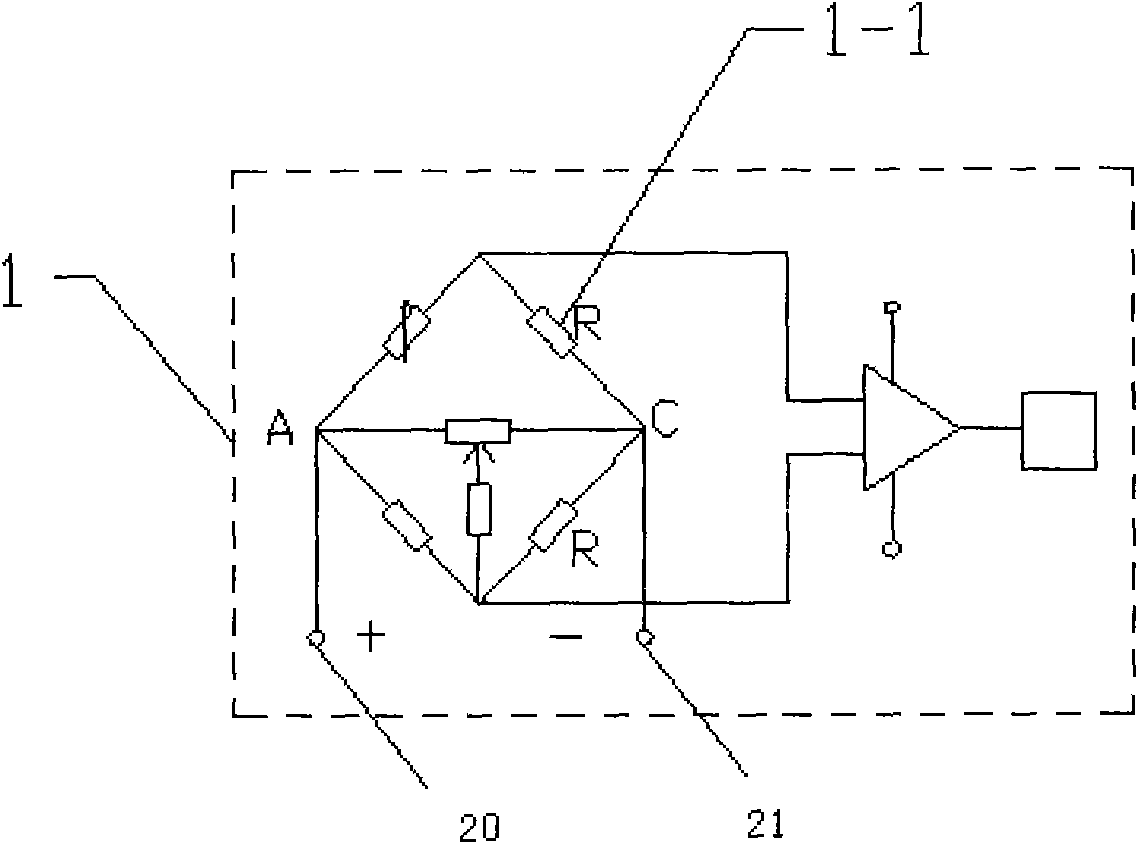

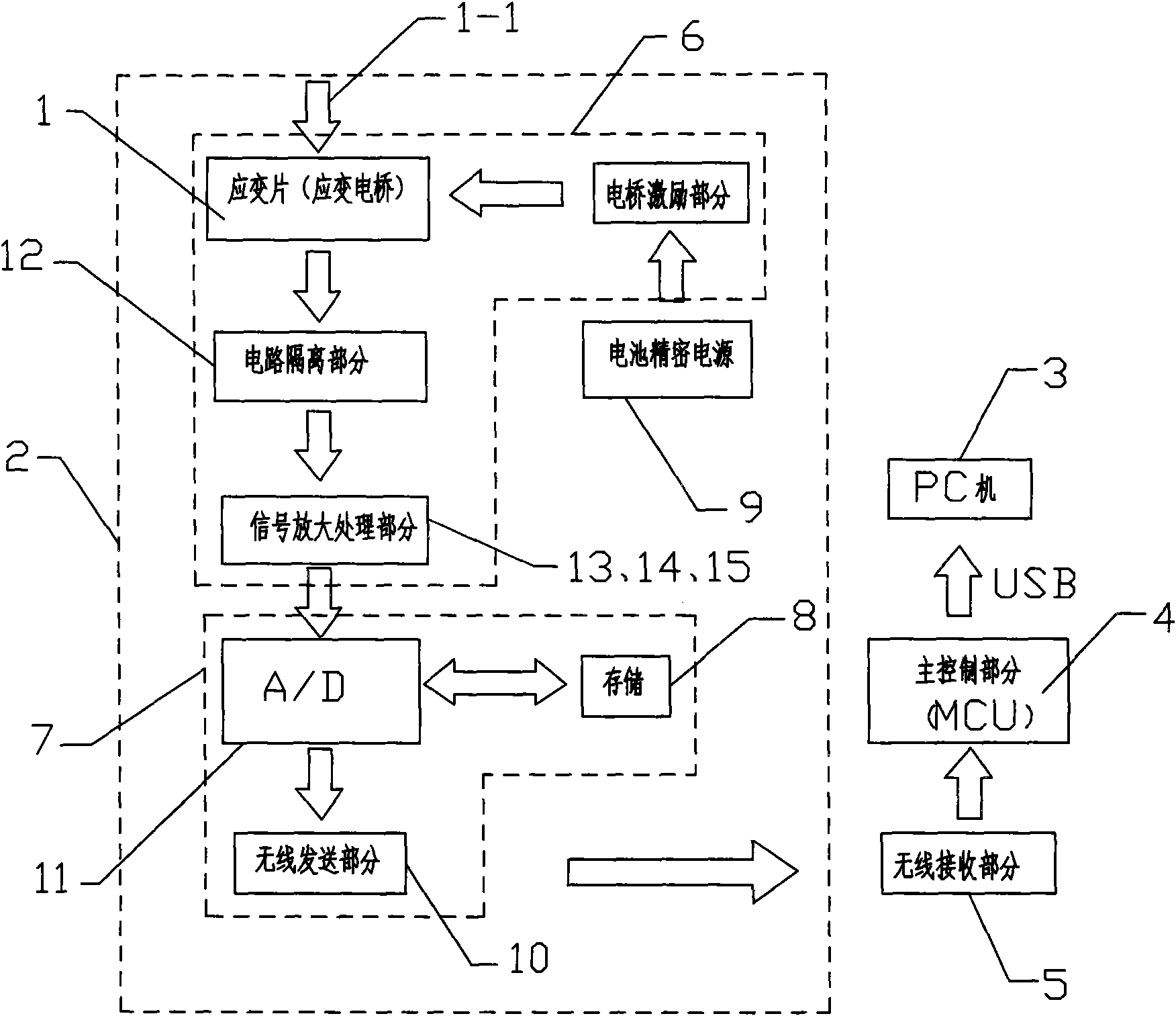

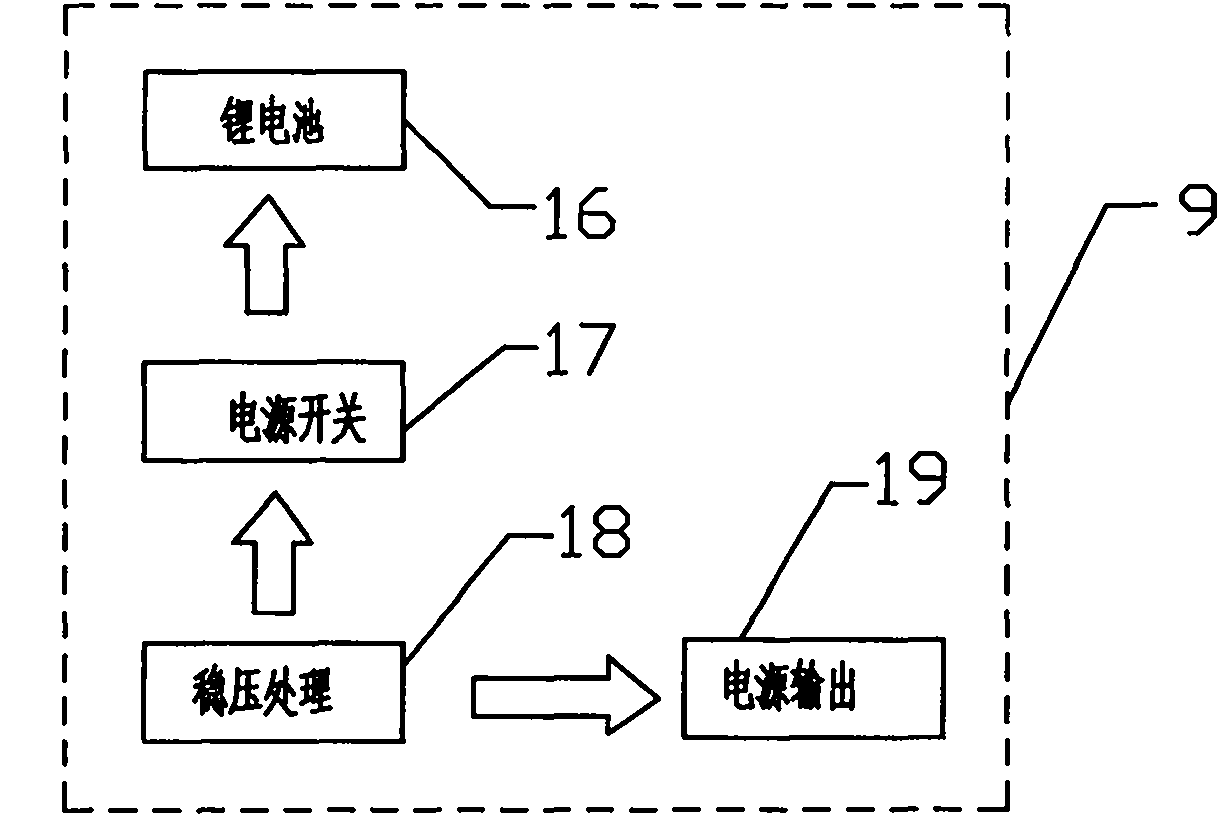

[0031] Below in conjunction with accompanying drawing, the present invention will be further described, figure 2 Among them, the wireless stress tester for hydropower units at least includes a lower distributed acquisition system 2 for signal acquisition, processing and storage and an upper and lower wireless signal transmitter 10, 5 for signal transmission; the lower distributed The acquisition system 2 includes a signal conditioner 6 for voltage and current conversion, filtering, overcoming signal drift, photoelectric isolation, electrostatic shielding and multi-stage amplification, an A / D conversion, storage, and and a lower master controller 7 for wireless transmission and a precision power supply 9 , the lower master controller 7 is composed of an A / D conversion and signal processor 11 , a data memory 8 and a lower wireless signal transmitter 10 . figure 1 with Image 6Among them, the signal conditioner 6 is provided with a strain bridge 1 for removing noise, amplifying...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com