Method for detecting weight of fingerprint resistant film of fingerprint-resistant electro-galvanized sheet

An electro-galvanized sheet and detection method technology, applied in the direction of removing certain component weighing, measuring devices, material weighing, etc., can solve problems such as difficult to find reagents, achieve accurate quantitative determination, and solve the effects of influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0025] 1 Reagents and materials

[0026] Note: During the analysis process, reagents of analytical grade should be used for preparing the test solution, and distilled water or deionized water should be used for the water used.

[0027] 1.1 Concentrated hydrochloric acid, ρ≈1.18g / mL.

[0028] 1.2 Hexamethylenetetramine, C 6 h 12 N 4 , Corrosion inhibitor, used to protect the steel base from acid corrosion when dissolving the coating.

[0029] 1.3 Zinc removal solution, add 500mL of hydrochloric acid (1.1) into a beaker containing 500mL of water and 3.5g of hexamethylenetetramine (1.2), and shake well.

[0030] 1.4 Closing material, acid-resistant paint or acid-resistant tape.

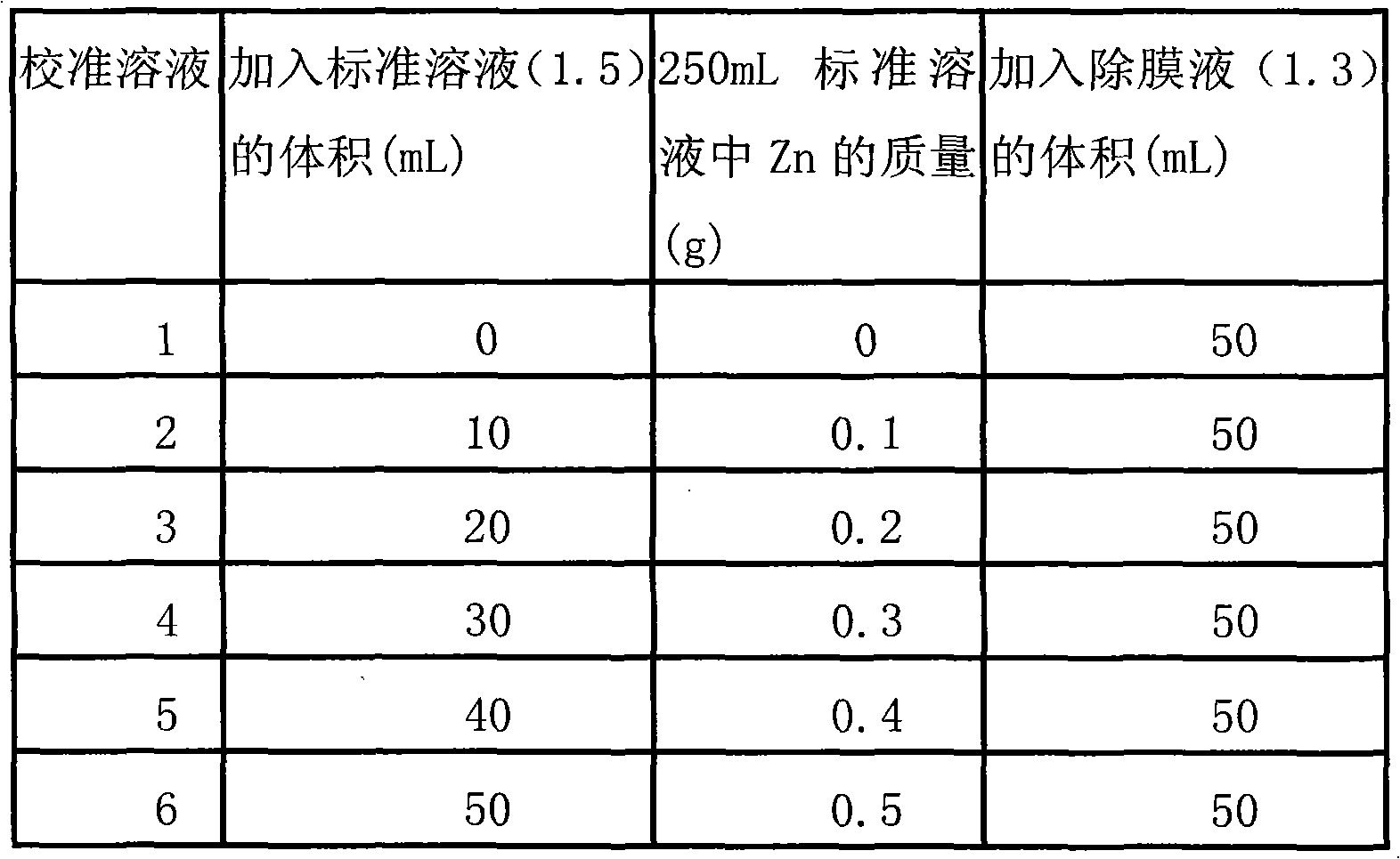

[0031] 1.5 Zinc standard solution, 10g / L, accurately weigh 10g of high-purity zinc (purity not less than 99.99%), accurate to 0.001g, dissolve in 100mL hydrochloric acid (1.1), transfer the solution into a 1000mL volumetric flask after cooling, Dilute to volume and shake well.

[0032] 1.6 Deterge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com