Contact reaction brazing connection method for TiAl based alloy and Ni based high-temperature alloy

A high-temperature alloy and contact reaction technology, which is applied in welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of silver brazing joints that are not resistant to high temperature, high requirements on the surface of the weldment to be welded, and long connection thermal cycle period. , to achieve the effect of good joint performance, high production efficiency and reduced welding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

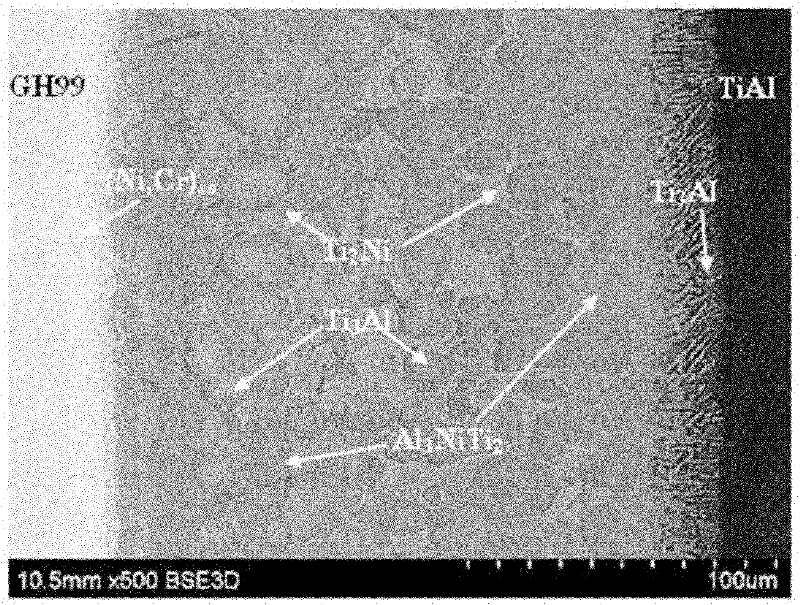

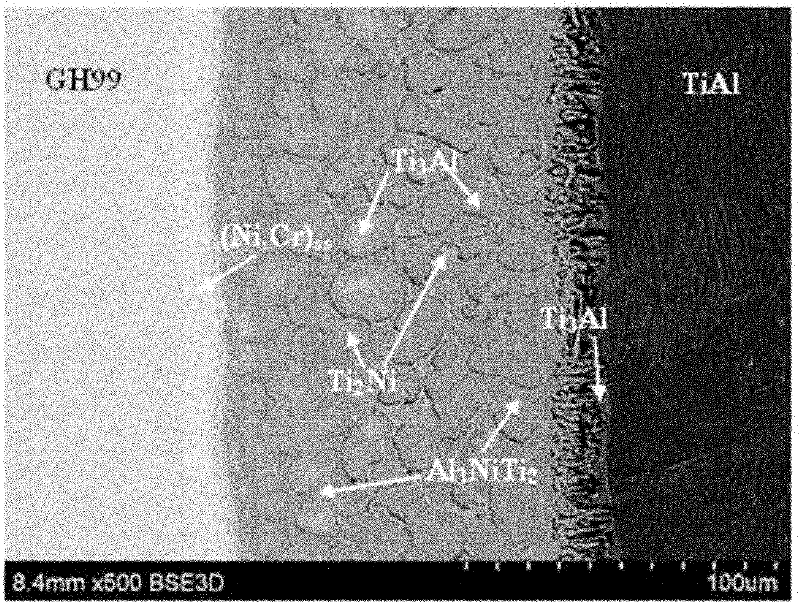

[0012] Specific embodiment 1: The contact reaction brazing connection method of the TiAl-based alloy and the Ni-based superalloy of this embodiment is carried out in the following steps: 1. The surface to be welded of the Ti foil, TiAl-based alloy and Ni-based superalloy is processed 2. Place the Ti foil between the TiAl-based alloy and the Ni-based high-temperature alloy to form the part to be welded; 3. Place the part to be welded in a vacuum brazing furnace and fix it with a pre-pressure of 0.001 MPa to 0.01 MPa, Then the vacuum degree is 1.0×10 -3 Pa~7.0×10 -3 Under the condition of Pa, heat up to 790℃~810℃ at a rate of 5℃ / min~20℃ / min, keep it for 8min~12min, then continue heating to 960℃~ at a rate of 5℃ / min~20℃ / min Keep the temperature at 1040℃ for 1min~30min, then cool to 300℃~500℃ at a rate of 5℃ / min~20℃ / min, then cool to room temperature with the furnace to complete the connection.

[0013] This embodiment uses a simple brazing method and commonly used inexpensive equipm...

specific Embodiment approach 2

[0014] Second embodiment: The difference between this embodiment and the first embodiment is that the thickness of the Ti foil in step one is 50 μm-100 μm. Others are the same as the first embodiment.

specific Embodiment approach 3

[0015] Specific embodiment 3: The difference between this embodiment and the specific embodiment is that the thickness of the Ti foil in step one is 80 μm. Others are the same as the first embodiment.

[0016] The shear strength of the contact reaction brazing joint of the TiAl-based alloy and the Ni-based superalloy obtained in this embodiment is 260 MPa to 290 MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com