A cmt welding process of 1cr18ni9ti stainless steel and 5a06 aluminum alloy

A welding process, stainless steel technology, applied in welding equipment, metal processing equipment, welding/welding/cutting articles, etc., can solve problems such as low weld strength, reduced weld strength of aluminum-steel connection, and reduced weld plasticity. Achieve the effects of improving reliability and stability, reducing welding heat input, and improving molding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

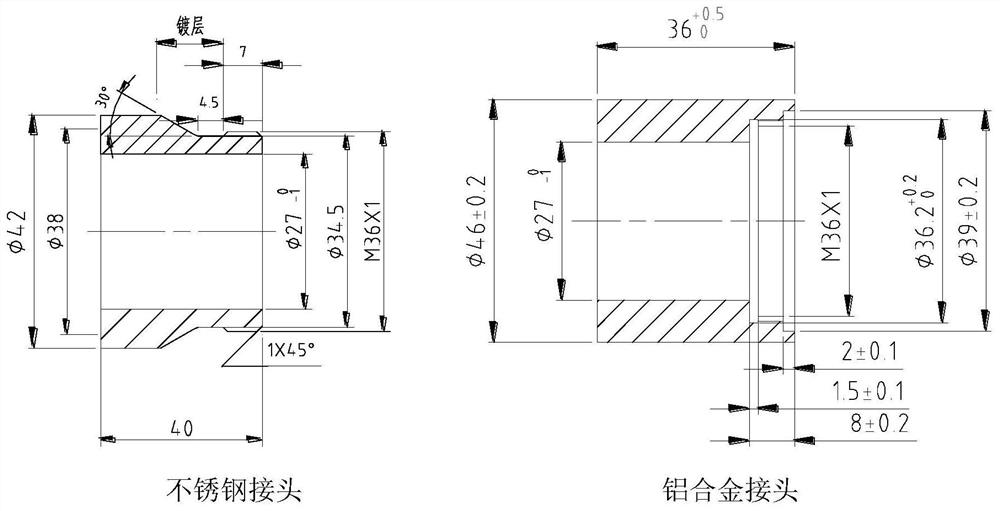

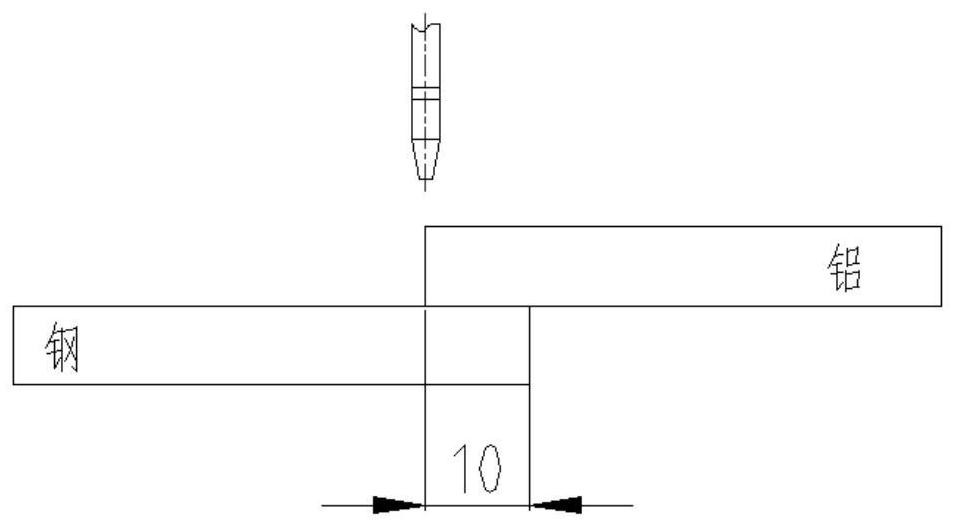

[0041] like figure 1 In the form of a lap joint structure shown, the wall thickness of the 1Cr18Ni9Ti stainless steel tube is 2 mm, and the wall thickness of the 5A06 aluminum alloy tube is 2 mm. The welding posture of this joint structure is as follows: figure 2 shown.

[0042] (1) The parts to be welded of steel pipes are processed with 11mm long external threads, and the parts to be welded of aluminum pipes are processed with 11mm long internal threads. Aluminum parts need to process welding groove: the groove angle is 30°, and the blunt edge is not more than 1mm;

[0043] (2) Polish the surface of the stainless steel to be welded, with a surface finish of 3.2 μm; pre-set an intermediate layer on the surface to be welded on the steel side: the thickness of the nickel layer is 3 μm; pre-treat the aluminum surface to remove the surface oxide layer;

[0044] (3) Assemble 1Cr18Ni9Ti stainless steel pipe and 5A06 aluminum alloy pipe to ensure that the gap between the two par...

example 2

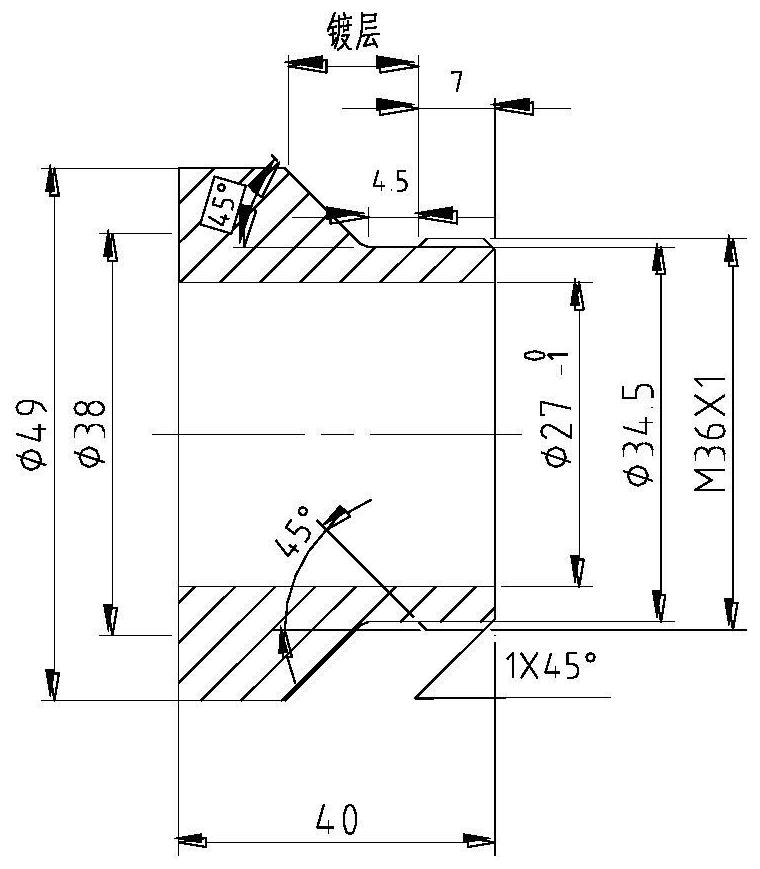

[0048] like image 3 Shown is a lap joint structure, 1Cr18Ni9Ti stainless steel tube wall thickness is 3mm, 5A06 aluminum alloy tube wall thickness is 3.5mm. The welding posture of this joint structure is as follows: figure 2 shown.

[0049] (1) The steel pipe to be welded is processed with a 15mm long external thread, and the aluminum pipe to be welded is processed with a 15mm long internal thread. Aluminum parts need to process welding groove: the groove angle is 45°, and the blunt edge is not more than 1mm;

[0050] (2) Polish the surface of the stainless steel to be welded, with a surface finish of 3.2 μm; pre-set an intermediate layer on the surface to be welded on the steel side: the thickness of the nickel layer is 4 μm; pre-treat the aluminum surface to remove the surface oxide layer;

[0051] (3) Assemble 1Cr18Ni9Ti stainless steel pipe and 5A06 aluminum alloy pipe to ensure that the gap between the two parts is not greater than 0.15mm, and the effective length of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com