Die matching device of liquid flow suspension ultraprecise cylinder polishing head

A polishing head and cylinder technology, applied in the direction of grinding devices, grinding/polishing equipment, metal processing equipment, etc., can solve the problems of reduced processing quality, affecting the uniformity of polishing, and long processing time, so as to reduce runout errors , Guarantee the effect of uniformity and high processing precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

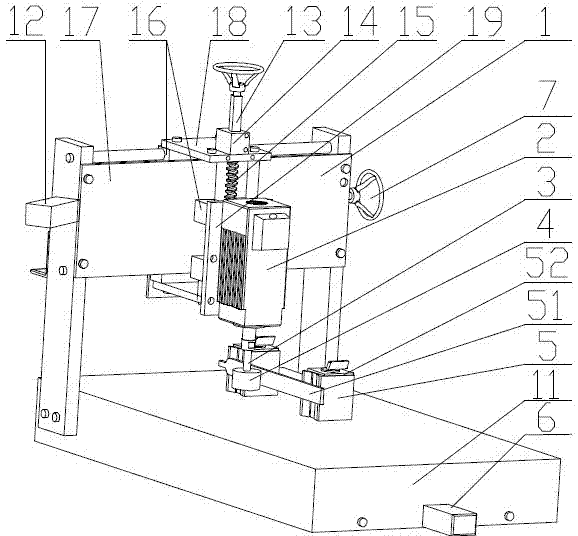

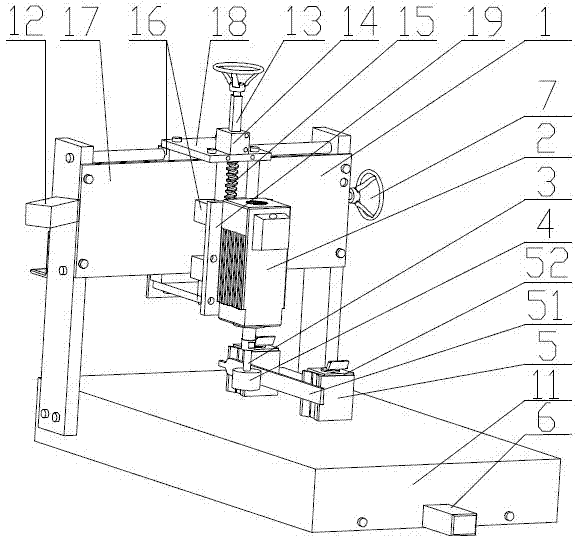

[0018] The present invention will be further described below in conjunction with accompanying drawing:

[0019] refer to figure 1 , the mold matching device of the liquid flow suspension ultra-precision cylindrical polishing head of the present invention includes a computer numerical control module 1 for eliminating the return error of the transmission screw 15, and the computer numerical control module 1 includes an X on the machine tool 6 To the stepper motor 11, Y to the stepper motor 12 and Z to the stepper motor 13, the described Z to the stepper motor 13 is connected with a shaft coupling 14, and the described shaft coupling 14 is connected with a transmission lead screw 15. The transmission lead screw 15 is provided with a slider 16 for adjusting its position, and the slider 16 is mated with the X-direction cage 17, the Y-direction cage 18 and the Z-direction cage 19, and the One side of the Z-direction cage 19 is fixed with a high-speed motor 2 for driving the process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com