A High Precision Grinding Technology and Application of Slender Shaft

A slender shaft, high-precision technology, applied in the direction of machine tools, grinding/polishing equipment, grinding machines, etc. designed for grinding the rotating surface of workpieces, it can solve the problems of spline hole quality, poor machining accuracy, coaxial To avoid problems such as poor degree of accuracy, to achieve good use effect and reduce jumping error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

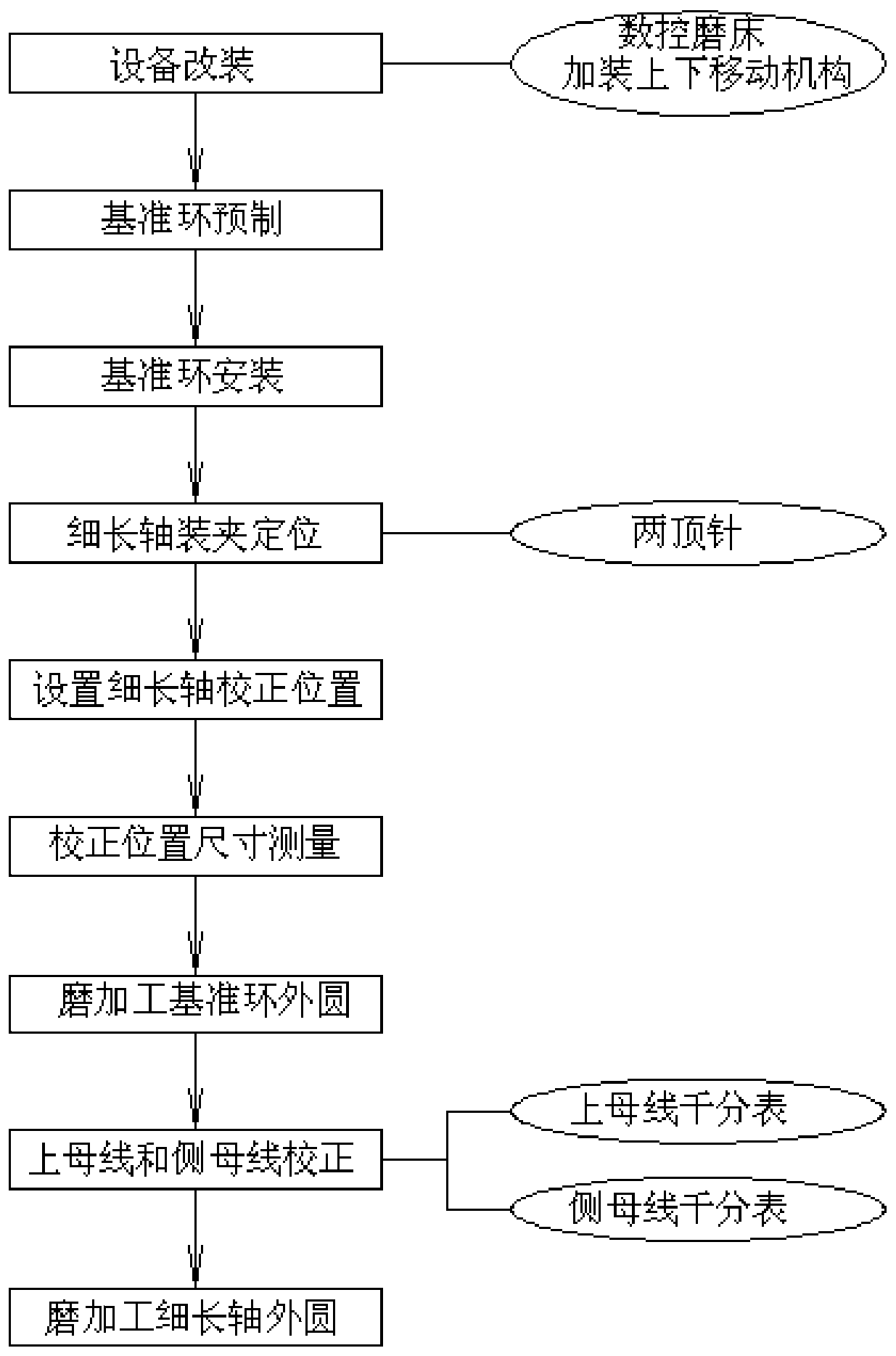

[0043] Such as Figures 1 to 3 Shown is the embodiment of the high-precision grinding process and application of a kind of slender shaft of the present invention, including the following process steps:

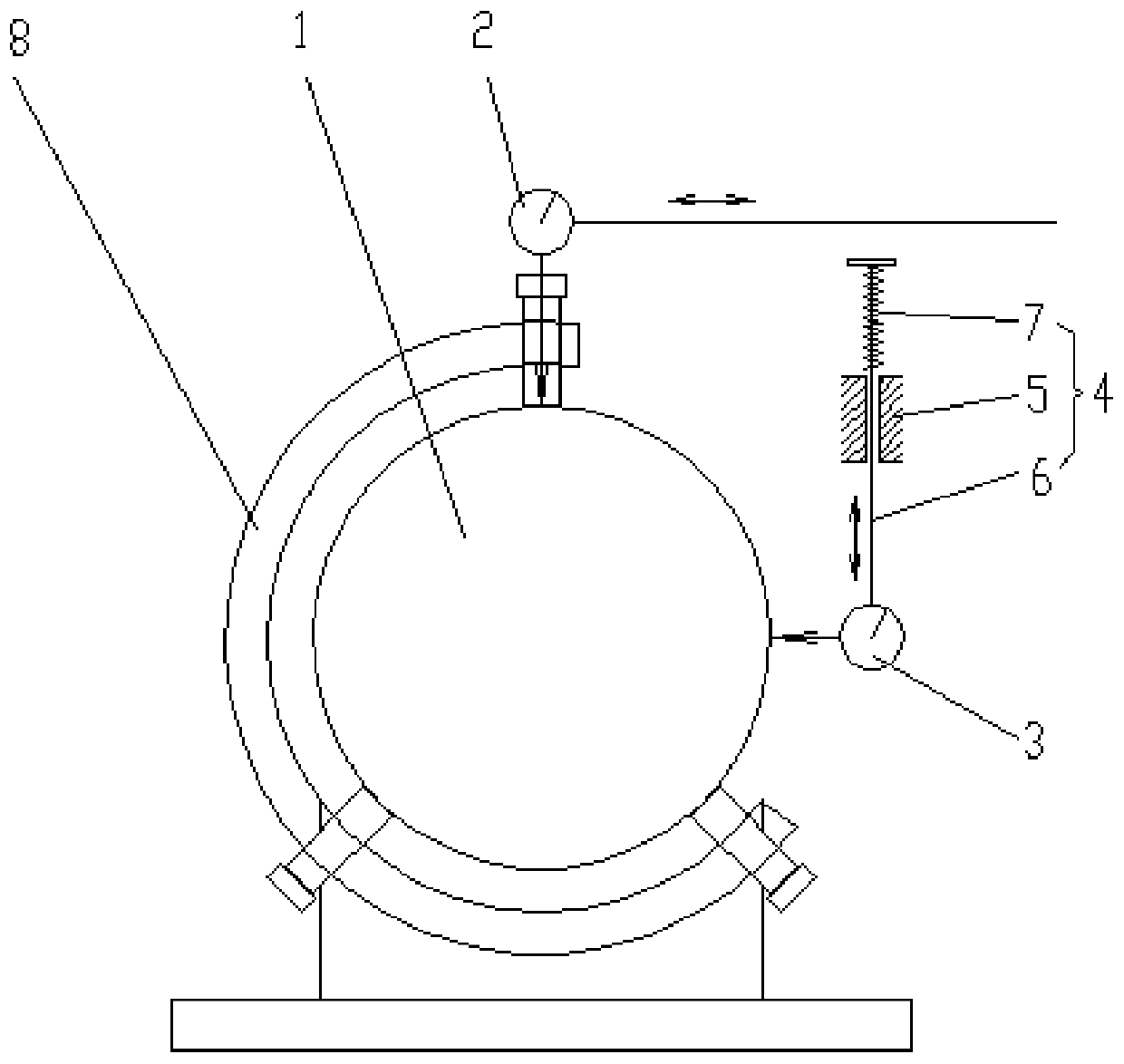

[0044] (1) Equipment refitting: a CNC cylindrical grinder is used as the equipment for cylindrical grinding of the slender shaft, and an upper bus bar dial indicator 2 for correcting the bus bar on the slender shaft 1 is installed on the grinding wheel headstock of the CNC cylindrical grinder; Simultaneously, install up and down moving mechanism 4 on the grinding wheel headstock of CNC cylindrical grinder, and install the side bus bar dial indicator 3 for correcting the side bus bar of slender shaft 1 on the moving arm 6 of described up and down moving mechanism 4;

[0045] (2) Reference ring prefabrication: Prefabrication of a reference ring matching the outer circle of one end of the slender shaft is used as a calibration tool for grinding the slender shaft, and the inner ho...

Embodiment 2

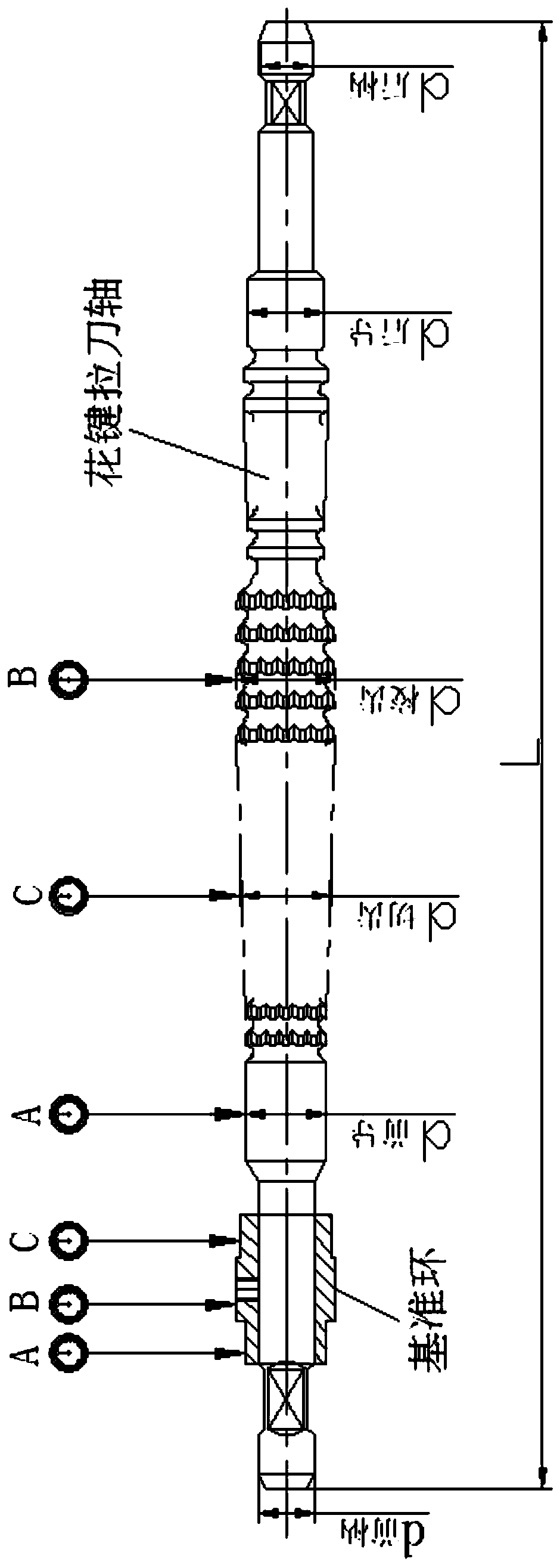

[0065] An application of the high-precision grinding process of the slender shaft of Embodiment 1, including applying the grinding process to grinding the outer circle of the spline broach shaft, and grinding the outer circle of the spline broach shaft After the grinding is completed, use a spline grinder to grind the tooth profile of the spline broach shaft, and before grinding the tooth profile of the spline broach shaft, use the reference ring and the center frame to pre-calibrate the upper generatrix of the outer circle of the tooth profile. , Side generatrix and radial circular runout are corrected to ensure that the outer circle of the N gear on the spline broach shaft is coaxial and the same size as the N gear outer circle on the reference ring.

[0066] Preferably, when grinding the tooth shape of the involute spline broach, the support point of the center frame is generally arranged on the leading outer circle of the broach and the specially ground roundness and radial...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com