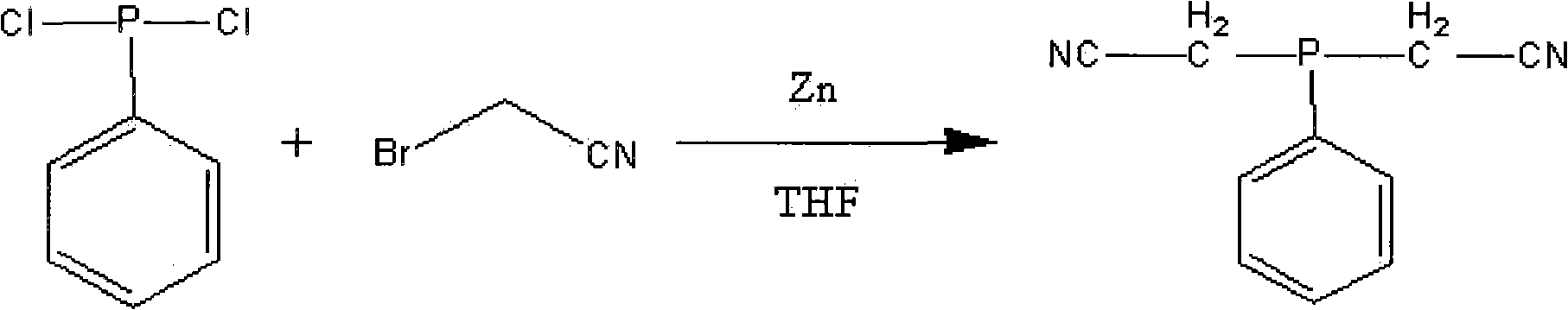

Method for preparing dicyanomethyl phenylphosphine

A technology of cyanomethylphenylphosphine and dicyanomethylphenyl, which is applied in the fields of chemical instruments and methods, compounds of Group 5/15 elements of the periodic table, organic chemistry, etc., can solve environmental pollution of waste residues and low yield and other problems, to achieve the effect of less by-products, simple production process, and obvious environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Install the reactor, add 1 mole of zinc powder and 30 moles of tetrahydrofuran to the reactor under the protection of nitrogen, and then dropwise dropwise a mixture of 1 mole of phenylphosphine dichloride, 2.2 moles of bromoacetonitrile and 5 moles of tetrahydrofuran at room temperature , The dropwise addition time was 1 hour, and after the dropwise addition was completed, the reaction was stirred at room temperature for 2 hours. After the reaction, the temperature of the solution in the reactor was raised to 50° C., and then the tetrahydrofuran and bromoacetonitrile in the solution were distilled off under a pressure of 60 mmHg. After steaming, add 10 moles of dichloromethane and 5 moles of water to the reactor, stir well, then let stand to separate layers, extract the upper organic layer, and then distill the organic layer at 60mmHg and room temperature to remove dichloromethane. After methane, the finished product of dicyanomethylphenylphosphine can be obtained. Aft...

Embodiment 2

[0024] Install the reactor, add 1 mole of zinc powder and 30 moles of tetrahydrofuran to the reactor under the protection of nitrogen, and then dropwise dropwise a mixture of 1 mole of phenylphosphine dichloride, 2.4 moles of bromoacetonitrile and 5 moles of tetrahydrofuran at 60 ° C. solution, the dropwise addition time was 1.5 hours, and the reaction was stirred at 60° C. for 2 hours after the dropwise addition was completed. After the reaction, the temperature of the solution in the reactor was kept at 60° C., and then the tetrahydrofuran and bromoacetonitrile in the solution were distilled off under a pressure of 60 mmHg. After steaming, add 10 moles of dichloromethane and 5 moles of water to the reactor, stir well, then let stand to separate layers, extract the upper organic layer, and then distill the organic layer at 60mmHg and room temperature to remove dichloromethane. After methane, the finished product of dicyanomethylphenylphosphine can be obtained. After testing,...

Embodiment 3

[0027] Install the reactor, add 1 mole of zinc powder and 10 moles of tetrahydrofuran to the reactor under the protection of nitrogen, and then dropwise dropwise a mixture of 1 mole of phenylphosphine dichloride, 2 moles of bromoacetonitrile and 10 moles of tetrahydrofuran at 70°C solution, the dropwise addition time was 2 hours, and the reaction was stirred at 70° C. for 3 hours after the dropwise addition was completed. After the reaction, the temperature of the solution in the reactor was kept at 70° C., and then tetrahydrofuran and bromoacetonitrile in the solution were distilled off under a pressure of 60 mmHg. After steaming, add 10 moles of dichloromethane and 5 moles of water to the reactor, stir well, then let stand to separate layers, extract the upper organic layer, and then distill the organic layer at 60mmHg and room temperature to remove dichloromethane. After methane, the finished product of dicyanomethylphenylphosphine can be obtained. After testing, the melti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com