Special material for infusion bottle (bag) ring pull covers and preparation method thereof

A technology for infusion bottles and ring caps, which is applied in the field of special materials for pull ring caps of infusion bottles and its preparation, and can solve the problems of high tensile strength, product rupture, and low elongation at break.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 4

[0047] A kind of preparation of infusion bottle (bag) ring cap special material:

[0048] After mixing polyethylene, polypropylene, polyolefin compatibilizers and nucleating agents, they are prepared and molded according to the test requirements. According to the required properties of the materials, they are tested for tensile properties, melt flow rate, and damp heat. Bacteria test and pull ring opening force test.

Embodiment 5

[0050] A kind of preparation of special material for pull-tab cap of medical infusion bottle (bag):

[0051] After mixing polyethylene, polypropylene, polyolefin compatibilizer, and nucleating agent, use twin-screw extrusion to granulate, prepare and shape according to the test requirements, and stretch them according to the required properties of the material Performance, Melt Flow Rate Testing, Moist Heat Sterilization Testing and Pull Ring Opening Force Testing.

Embodiment 6

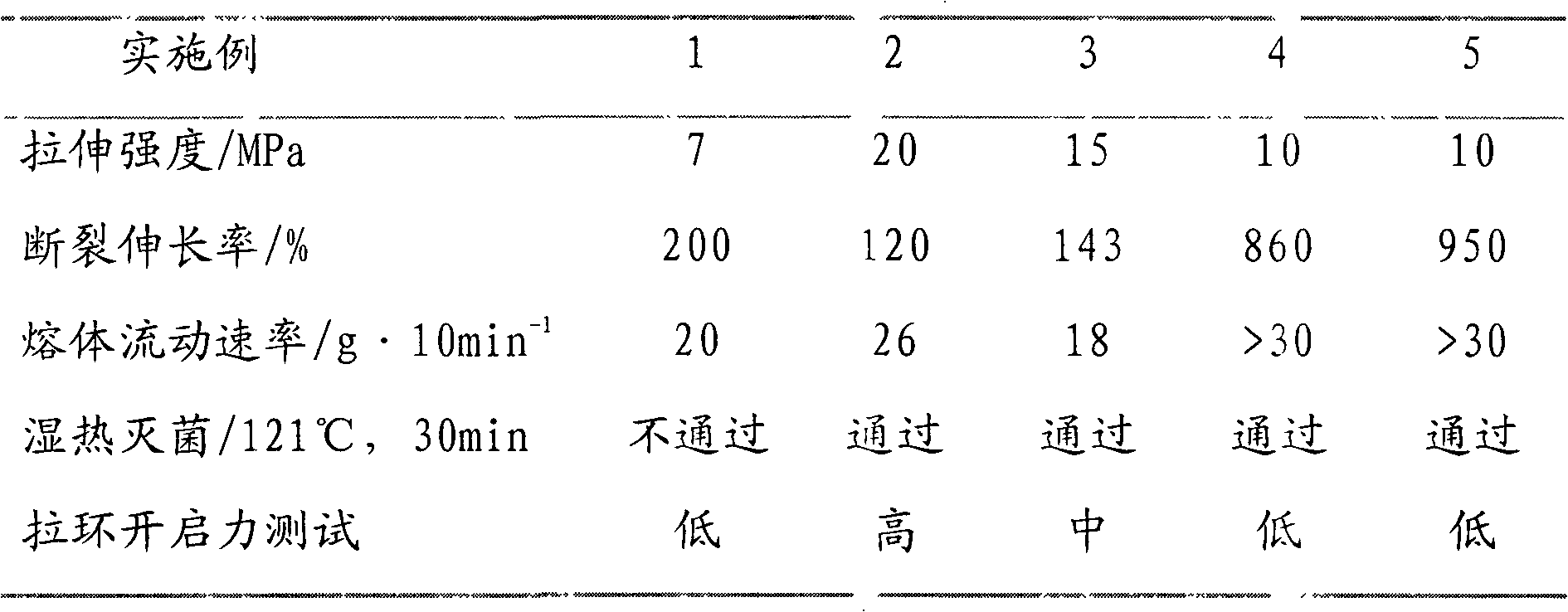

[0053] With the compositions prepared by comparative example 1, comparative example 2, comparative example 3, embodiment 4 and embodiment 5, after the preparation and molding according to the test requirements, by the required properties of the material, they are subjected to tensile properties , Melt flow rate test, moist heat sterilization test and pull ring opening force test. The test results are shown in Table 1.

[0054] The tensile property test of the material is carried out according to the method described in GB / T 1040-92, the melt flow rate test of the material is carried out according to the method described in GB / T 3682-2000, and the test of moist heat sterilization and pull ring opening force is carried out according to the "National Drug Packaging Containers (Materials) Standard - Infusion Containers with Polypropylene Combination Caps "YBB002-2004" method. The test results are shown in Table 1

[0055] Table 1 Material performance test

[0056]

[0057] A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com