High gradient magnetic separation of biological material

A biological material, magnetic separation technology, applied in high gradient magnetic separation, high gradient magnetic separator, magnetic separation and other directions, can solve problems such as non-specific binding, achieve simple cost and improve the effect of purification results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

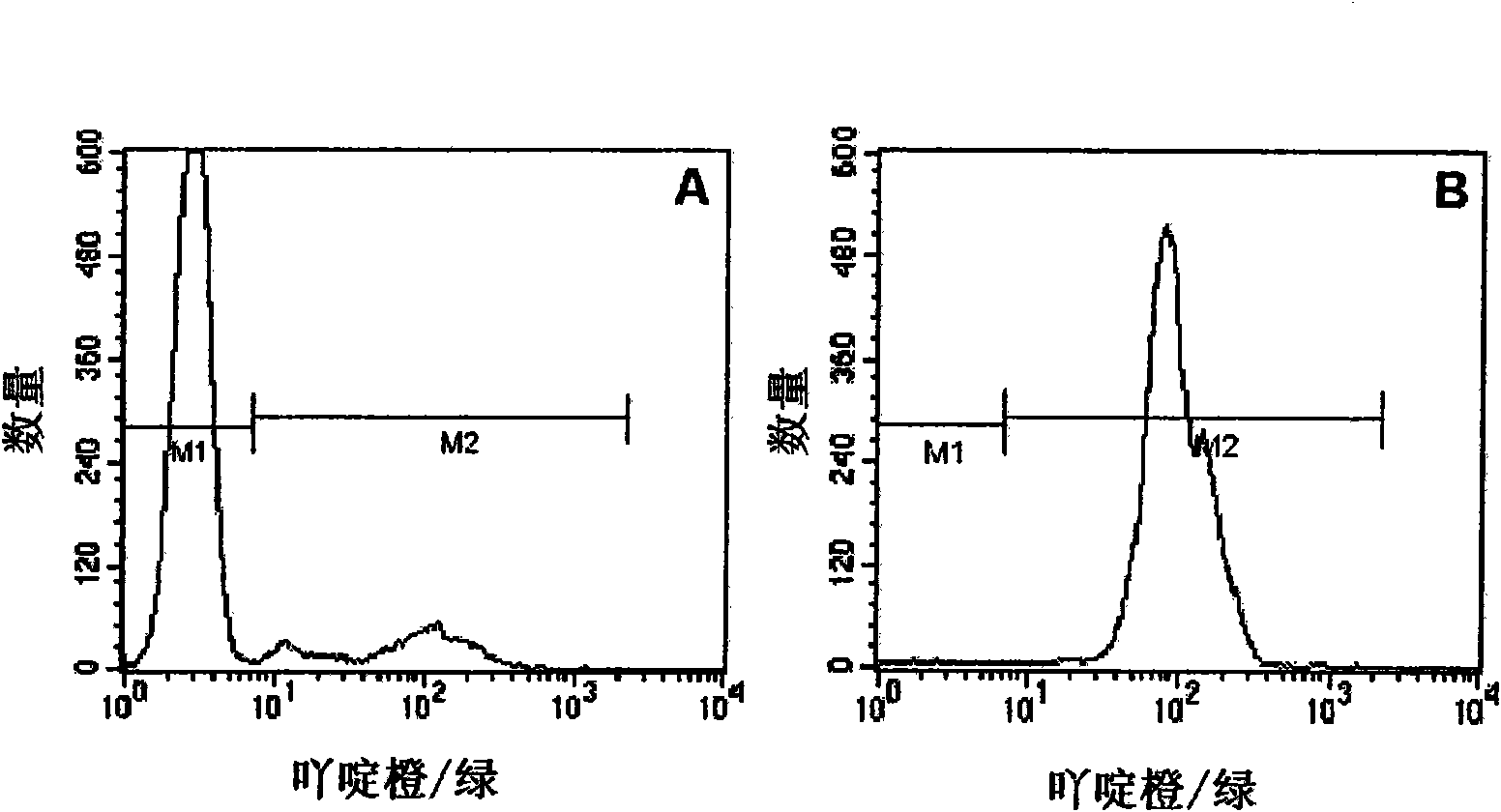

[0072] Using isotonic phosphate-buffered sucrose solution containing gelatin against Plasmodium falciparum (P.falciparum) cultures of red blood cells infected with the malaria pathogen (Plasmodium) purification.

[0073] Material:

[0074] buffer solution A 1 : Isotonic phosphate-buffered sucrose solution containing 0.75% gelatin

[0075] Stainless steel wool 1g

[0076] single tap

[0077] three way tap

[0078] 20G injection needle

[0079] 3ml disposable syringe

[0080] 10ml disposable syringe

[0081] 50ml disposable syringe

[0082] 1 neodymium horseshoe magnet

[0083] a) Preparation of purification kit

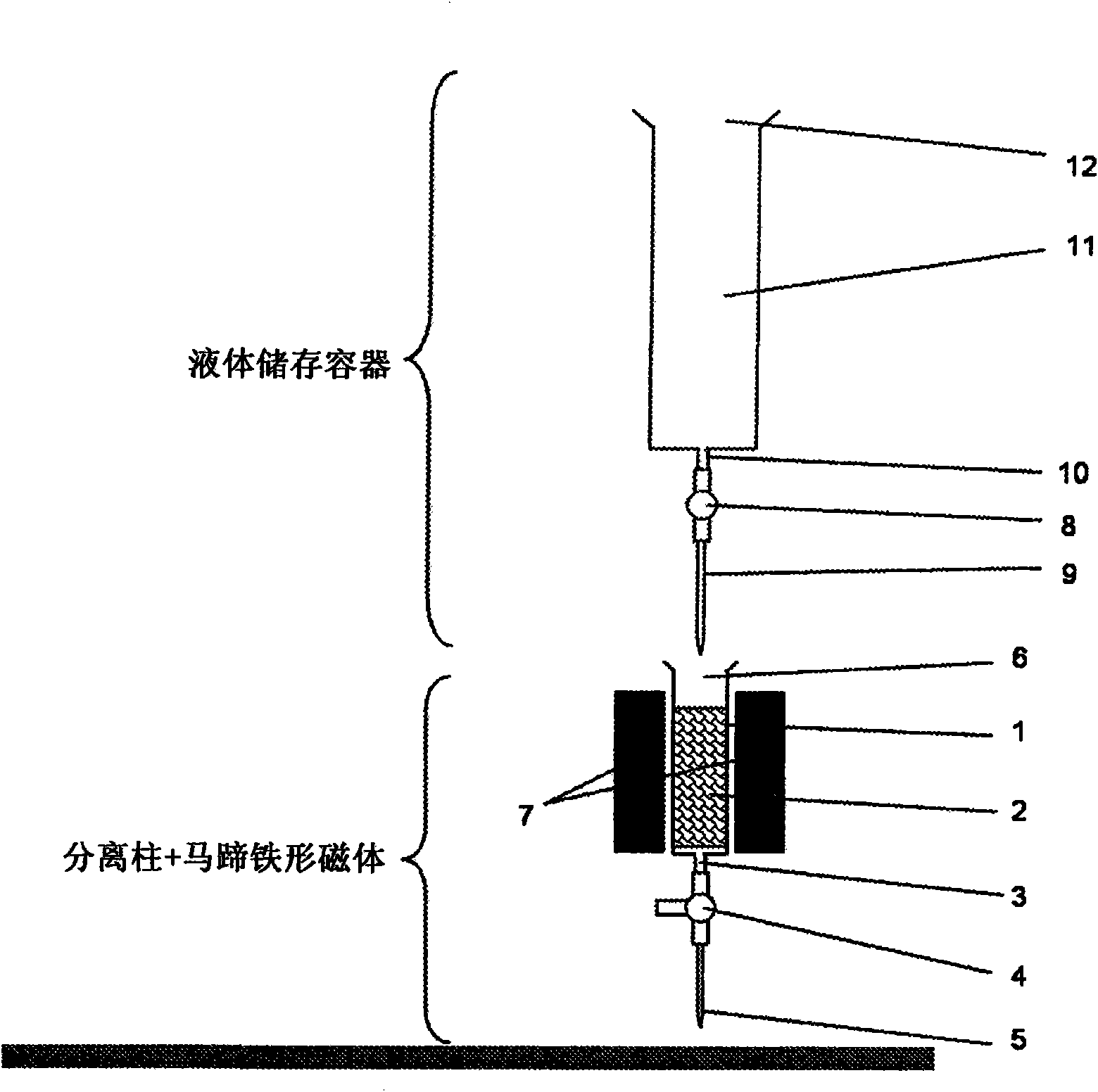

[0084] Manufacture of Separation Columns

[0085] A 3 ml disposable syringe used as separation column 1 was filled with 1 gram of stainless steel wool as matrix 2 to two-thirds of the total volume of the 3 ml disposable syringe. Here, it should be noted that a large number of stainless steel wool fibers are located in the longitudinal direction of the ...

example 2

[0098] Use phosphate-buffered saline solution (PBS) containing bovine serum albumin (BSA) Purification of malaria pathogens (Plasmodium) from cultures of P. falciparum infected red blood cells

[0099] Material:

[0100] As listed in Example 1, but with Buffer A 1 buffered solution A 2 (PBS with 5% BSA) instead.

[0101] a) Preparation of purification kit

[0102] Follow the description in Example 1.

[0103] b) Preparation and execution of the separation process

[0104] Preparation of P. falciparum cultures for purification of red blood cells infected with the malarial pathogen

[0105] As in Example 1. The parasitemia of the P. falciparum culture in this experiment was 14.47%. buffer solution A 1 with buffer solution A 2 replace.

[0106] Execution of the separation process

[0107] As in Example 1, with the following differences:

[0108] buffer solution A 1 with buffer solution A 2 replace. Centrifugation of the eluate was then performed at 800 g for ...

example 3

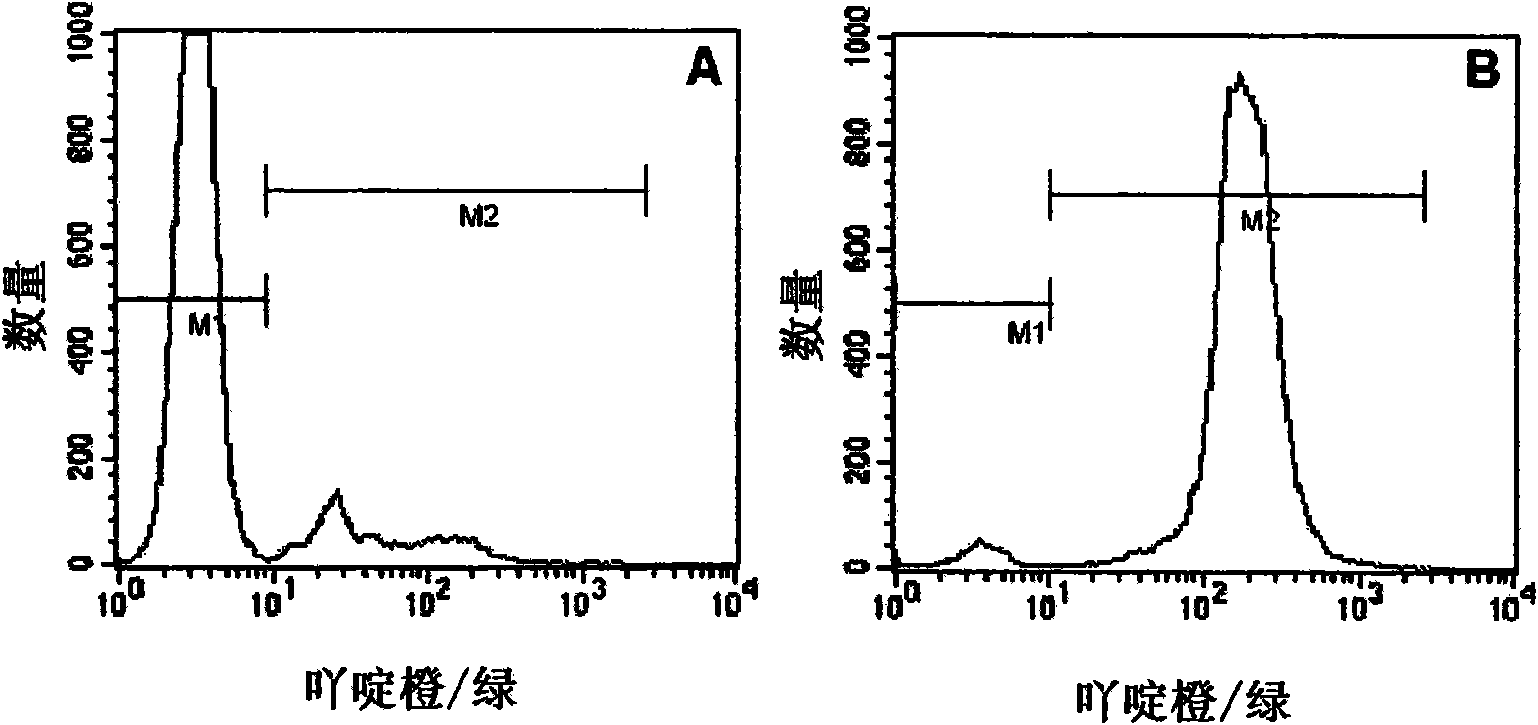

[0112] Purified from a suspension of leukocytes (peripheral blood mononuclear cells (PBMCs)) Original CD8 leukocytes (CD8 positive cells).

[0113] Material:

[0114] as listed in Example 1.

[0115] a) Preparation of purification kit

[0116] Follow the description in Example 1.

[0117] b) Preparation and execution of the separation process

[0118] Labeling of CD8-positive cells with antibody-conjugated synthetic paramagnetic particles (microbeads)

[0119] will be 1.5x10 7 Individual human peripheral mononuclear cells (PBMCs) were incubated with monoclonal rat anti-human CD8 IgG antibody in PBS / BSA 1% for 30 minutes on ice. The cells were washed twice with the same buffer solution, and then incubated with anti-rat IgG-coupled microbeads (MiltenyiBiotech GmbH, loc. cit.) for an additional 10 minutes on ice. The cells were washed twice in the same buffer solution, and then with fluorescein-labeled antibodies (PE-anti-CD8 antibody and FITC-anti-CD3 antibody, Simulte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Gel strength | aaaaa | aaaaa |

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com