Process for synthetic lubricant production

A technology of catalyst and accelerator, applied in the field of synthetic lubricant preparation, which can solve problems such as loss of lubricating oil yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

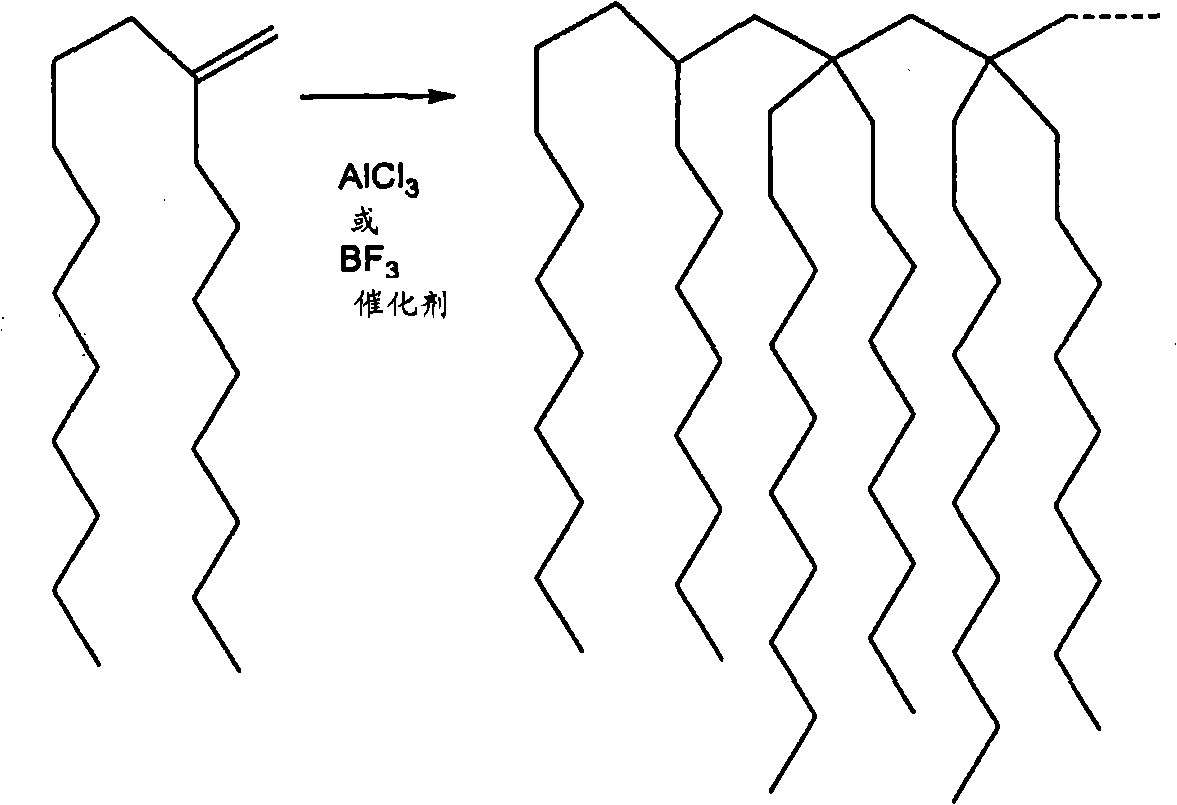

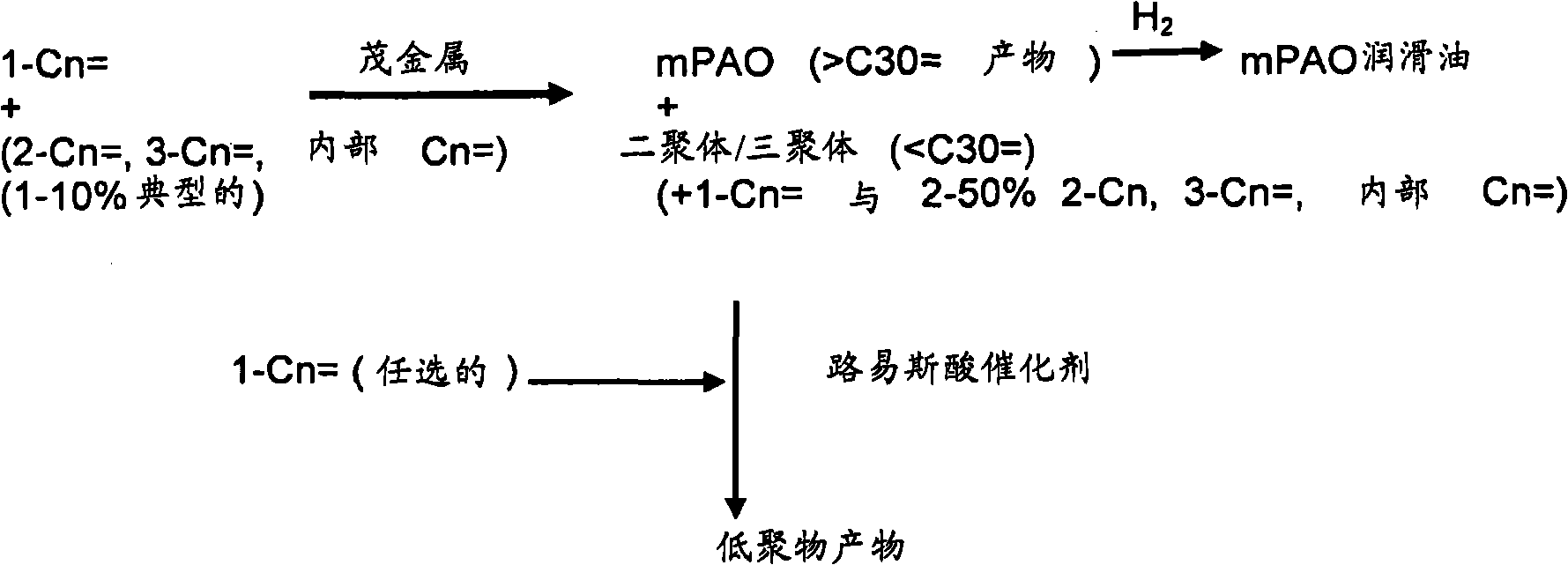

Method used

Image

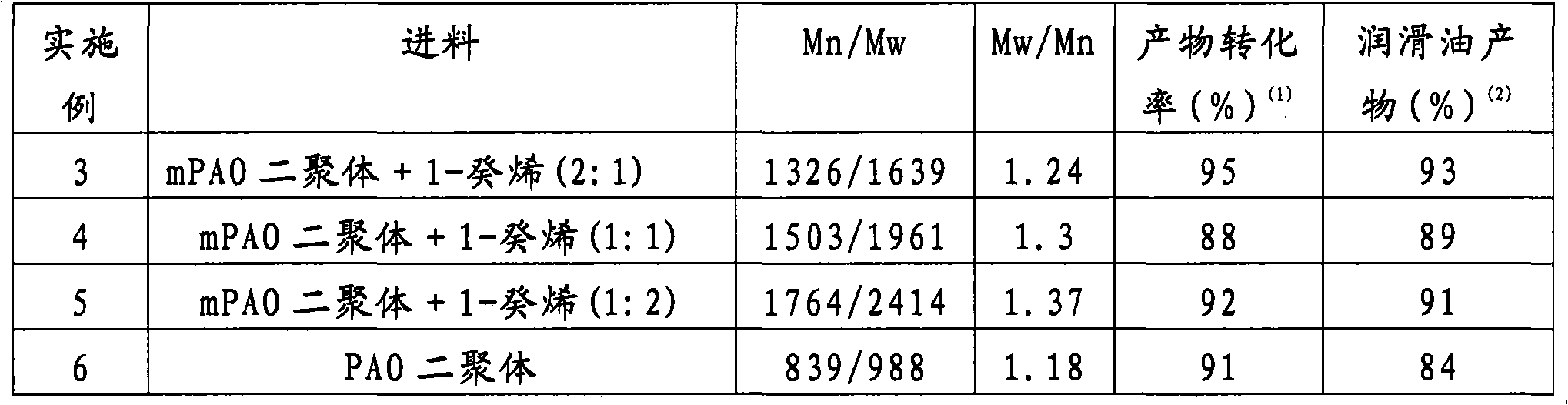

Examples

Embodiment

[0040] Metallocene PAOs can be synthesized using batch mode operation using the following exemplary procedure. A stock solution of purified 1-decene (50 g) and 3.173 g of triisobutylaluminum (TIBA) was injected into a 500 ml flask under nitrogen atmosphere. The reaction flask was then heated to 120° C. with stirring. Another funnel installed on the reaction flask contains 20g toluene, 0.079g TIBA raw material solution, 0.430g rac-ethylenebis(4,5,6,7-tetrahydro-1-indenyl) dichloride A solution of zirconium solution and 0.8012 NCA stock solution was added to the 1-decene mixture within 15 minutes while maintaining the reaction temperature close to 120°C, not more than 3°C up or down. The reaction mixture was stirred at the reaction temperature for 16 hours. The heat was then switched off and the mixture was quenched with 3 ml of isopropanol. The crude product was then washed three times with 100 ml of 5% aqueous NaOH followed by 100 ml of deionized water. The organic layer w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

| pour point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com