Stacked conduit assembly and screw fastening method for conduit part

A technology of assembly and pipeline, applied in the direction of circuit, thin plate connection, connecting components, etc., can solve the problems of cost increase, processing process increase, unfavorable thinning, etc., and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

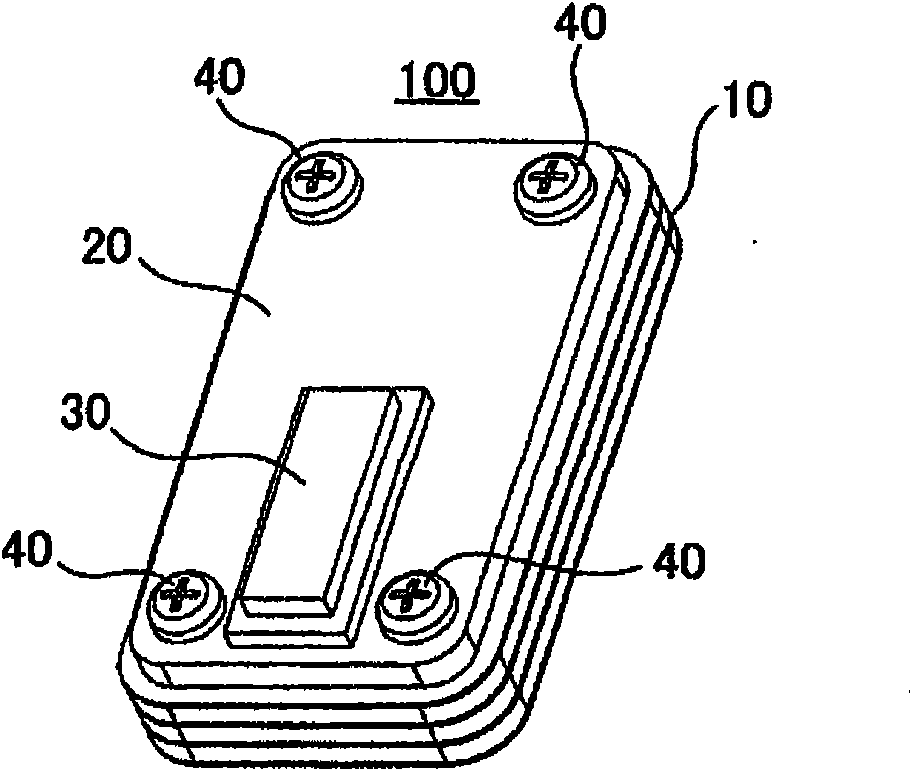

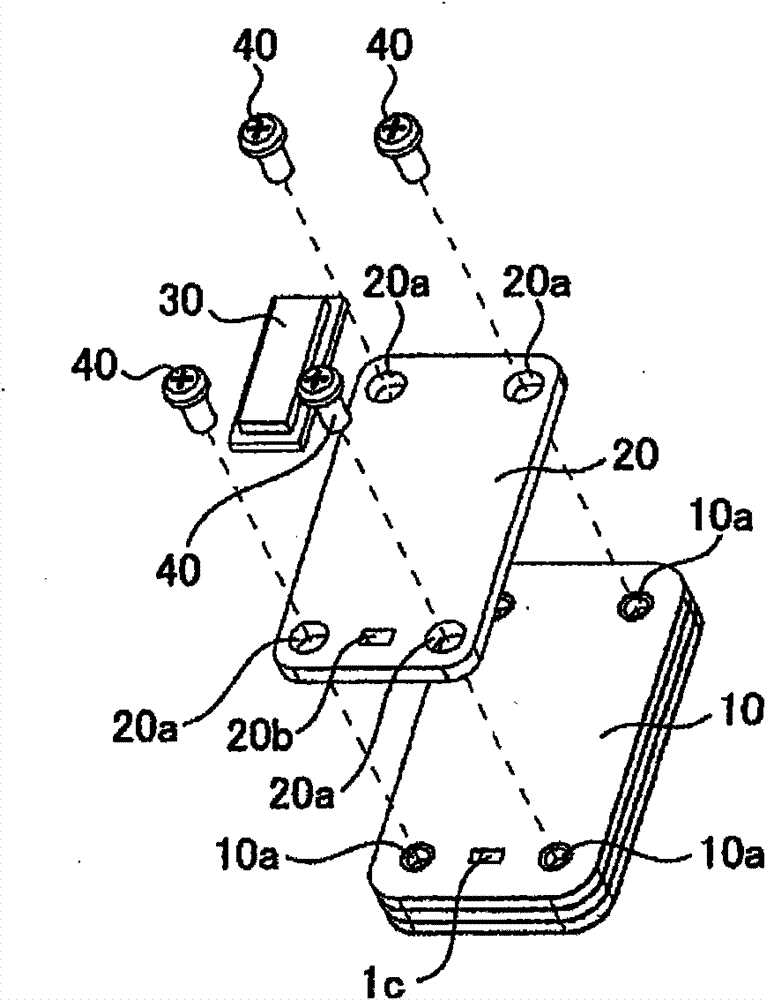

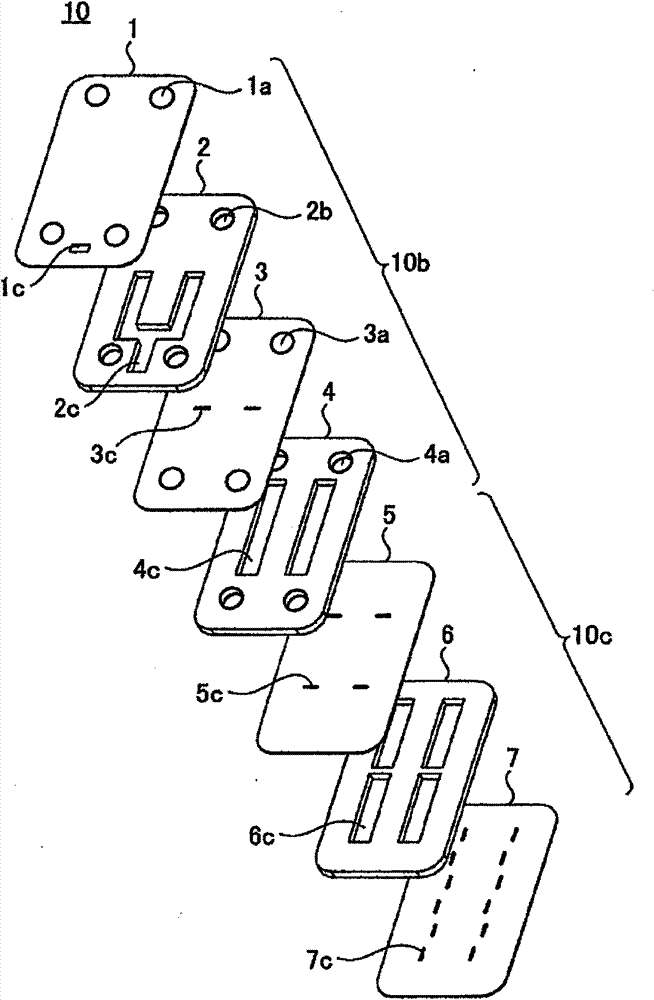

[0031] figure 1 It is a perspective view showing Embodiment 1 of the laminated piping assembly of the present invention. figure 2 yes figure 1 An exploded perspective view of the stacked tubing assembly of . The laminated pipe assembly 100 has: a waveguide pipe part (pipe part) 10; a control substrate 20 as a connected part connected to the waveguide pipe part 10 by self-tapping screws 40; High frequency device 30 on 20. The high-frequency device 30 has a function of transmitting and receiving microwaves or millimeter waves. The waveguide piping component 10 is formed by stacking a plurality of sheet-like components and integrating them by surface bonding. The waveguide pipe component 10 has a hollow pipe (waveguide) not shown formed in the inner layer. Bottom holes 10a for screws are formed on the waveguide pipeline part 10. On the other hand, a through hole 20a is formed on the control substrate 20, and the control substrate 20 is driven into the waveguide pipeline by ...

Embodiment approach 2

[0041] The structure of the laminated piping assembly of the present embodiment is roughly the same as that of the first embodiment. When the material of the waveguide pipeline part 10 is stainless steel, it is generally difficult to connect with self-tapping screws due to its high hardness (Vickers hardness is 250Hv or more) (it can be done with general self-tapping screws). The approximate standard of the hardness of the material to be connected is less than 50% of the screw hardness, 220Hv or less).

[0042] Therefore, in the present embodiment, the entire waveguide line component 10 or the chip component 2 forming the bottom hole 2b is annealed at about 800° C. (heat treatment step). Thereby, the hardness is reduced to 220Hv or less, and a structure capable of screwing can be realized even for stainless steel components.

[0043] In addition, regarding the above-mentioned heat treatment, when a bonding method by high-temperature heating typified by diffusion bonding is us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com