Dust adhering roller and manufacturing method thereof

A manufacturing method and technology of rollers, applied in the directions of cleaning methods and utensils, chemical instruments and methods, adhesive types, etc., can solve the problems of hard rollers, damaged printed circuit boards, and inability to completely transfer foreign objects, and achieve adhesion. The effect of mildness, improving ergonomics and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

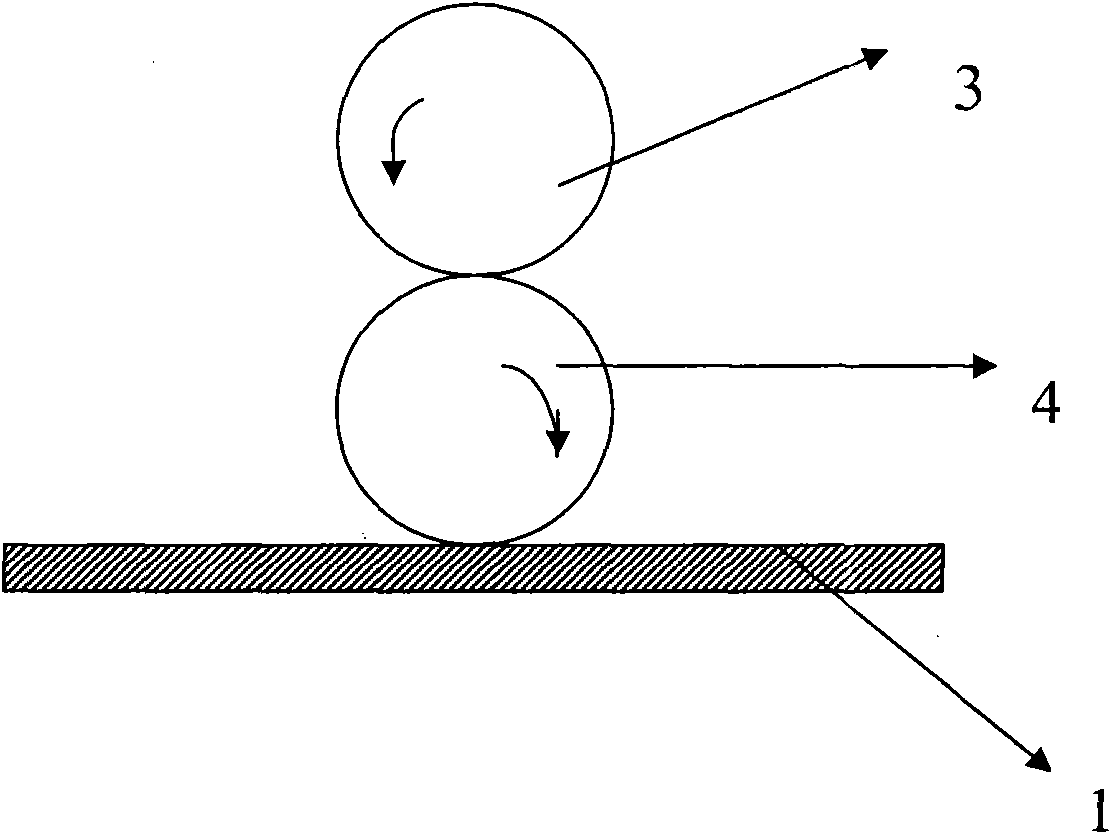

[0028] The features and advantages of the present invention are described in detail below in conjunction with the accompanying drawings:

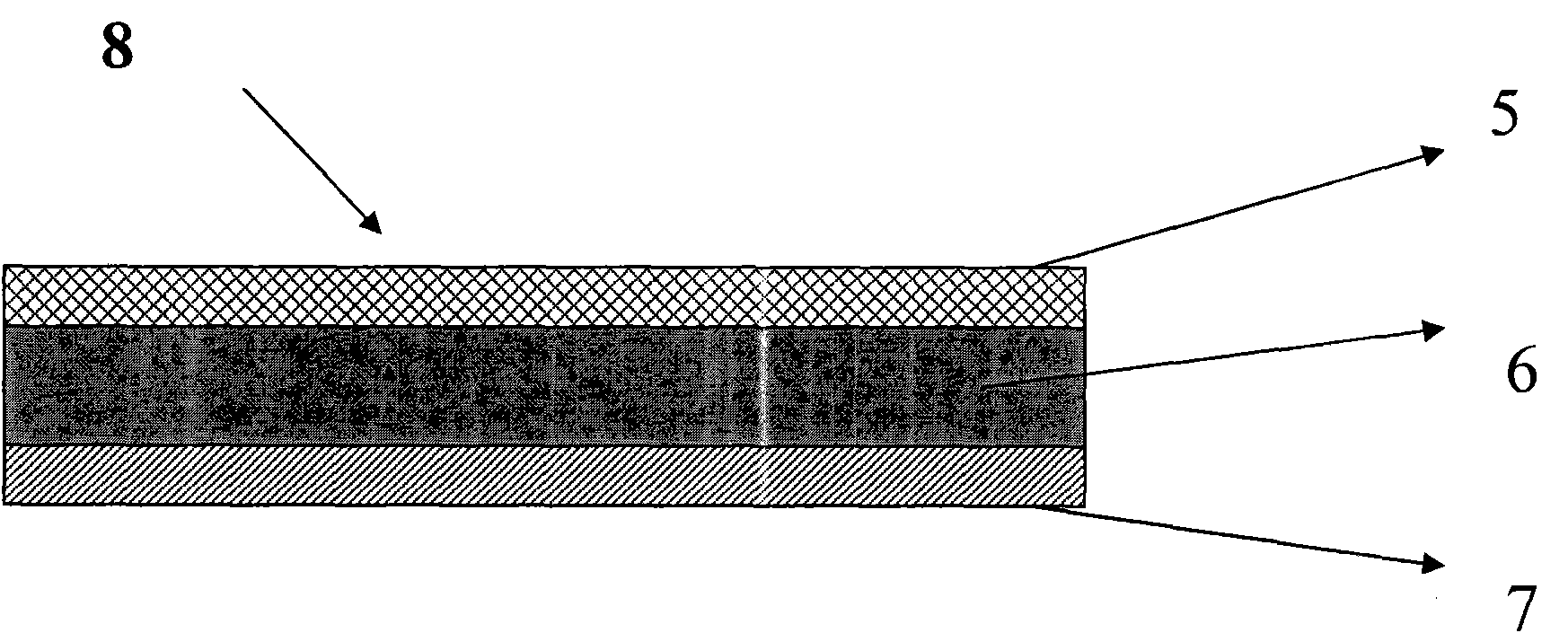

[0029] like figure 2 , image 3 The shown dust sticking roller of the present invention includes a sticky cloth 8 wound on a reel, including: the sticky cloth 8 includes a pressure-sensitive adhesive layer 5 and a base material layer 6 stacked on each other. The agent layer 5 is formed by uniformly coating the pressure-sensitive adhesive on one side of the base material layer 6 .

[0030] Wherein, the pressure-sensitive adhesive layer 5 is made of the following substances and parts by mass: a. 50-60 parts of butyl acrylate; b. 5-10 parts of ethyl acrylate; c. 5-10 parts of vinyl acetate; d. 1-5 parts of hydroxypropyl acrylate; e. 0.2-5 parts of acrylic acid; f. 50-60 parts of ester solvent; g. 2-5 parts of multifunctional crosslinking agent; h. 0.1-0.5 part of acid catalyst. Among them, the preferred formula and proportion of parts by m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com