Method for constructing oil drilling waste mud solidification pool

A technology for waste mud and oil drilling, which is applied to buildings, building types, underwater structures, etc. It can solve the problems of ponds not playing an anti-seepage role, increasing curing costs, and overflowing waste mud, so as to achieve long-term protection against leakage. , the effect of promoting coordinated development and shortening the construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

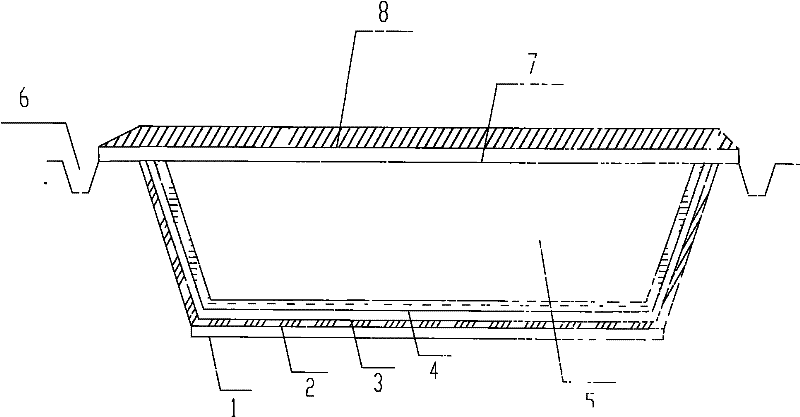

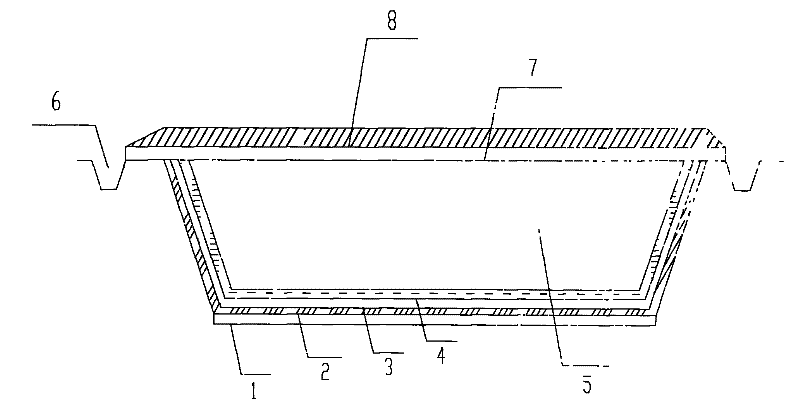

[0037] The invention discloses a method for constructing an oil drilling waste mud solidification pool, which comprises the following steps: a. Excavating an earthen pool and compacting the pool body; b. Removing sharp debris on the inner wall of the earthen pool, and laying a clay layer on the bottom of the earthen pool 1, the clay layer 1 is compacted; c, the bottom layer of non-woven geotextile 2, the polyethylene geomembrane 3 and the surface layer of non-woven geotextile 4 are sequentially laid on the inner wall of the earthen pond to form a three-layer structure, and the surface of the non-woven geotextile is Fill the waste mud 5 in the layer 4, and use the three-layer structure to wrap the waste mud 5; d, lay a concrete layer 7 on the three-layer structure wrapped with the waste mud 5; e, cover the concrete layer 7 with a Layer cooked soil 8.

Embodiment 2

[0039] As the best implementation mode of the present invention is as follows: with reference to figure 1 , the present invention includes: a, excavating the earthen pond, and tamping the pond body; b, removing the sharp debris on the inner wall of the earthen pond, and laying a clay layer 1 at the bottom of the earthen pond, and compacting the clay layer 1; c, on the inner wall of the earthen pond Lay non-woven geotextile bottom layer 2, polyethylene geomembrane 3 and non-woven geotextile surface layer 4 in sequence to form a three-layer structure, fill waste mud 5 into the non-woven geotextile surface layer 4, and use the three-layer The structure wraps the waste mud 5; d, laying a concrete layer 7 on the three-layer structure wrapped with the waste mud 5; e, covering a layer of mellow soil 8 on the concrete layer 7. After any of the steps a-e, a drainage ditch 6 is dug outside the pool, and the concrete layer 7 is extended to the drainage ditch 6 . In the concrete layer 7,...

Embodiment approach

[0042] (1) Excavate the solidification pool according to the terrain, try to be within 50m of the sewage pool, the depth of the pool is 2.5-3m, the length and width are not more than 20m, and the slope of the slope is 45°-60°.

[0043] (2) Compact the bottom and sides of the pool, remove sharp debris, and use 20cm of clay at the bottom and compact it.

[0044] (3) High-density polyethylene geomembrane 3 (1.5mm) uses upper and lower layers of non-woven geotextiles as the protective layer. Before laying the geomembrane, lay the geotextile, and then lay a layer of geotextile. The geotextile joints are lapped. The amount of contact is between 20-30cm.

[0045] (4) Lay high-density polyethylene geomembrane 3 and the welding sequence extends from the height of the pool to the bottom. The overlap between the two membranes is between 10-20cm. The joint must be clean and free of water drops, so as not to affect the welding quality. The welding adopts hot-press fusion welding, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com