Self-positioning detachable concrete durability test stress loading device

A technology of durability testing and stress loading, which is applied to measuring devices, using stable tension/pressure to test the strength and strength characteristics of materials, etc. Convenience, reduced stress relaxation, easy to grasp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

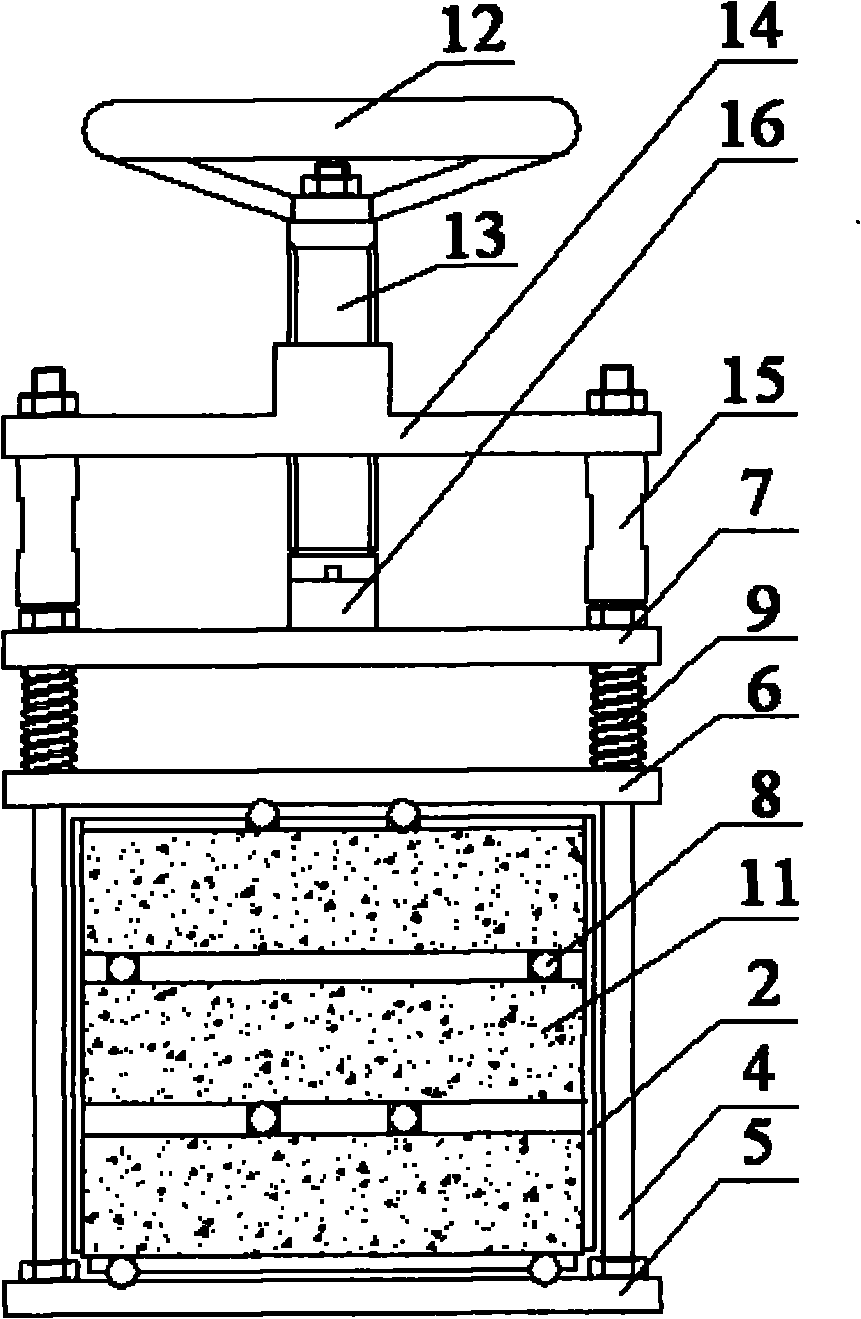

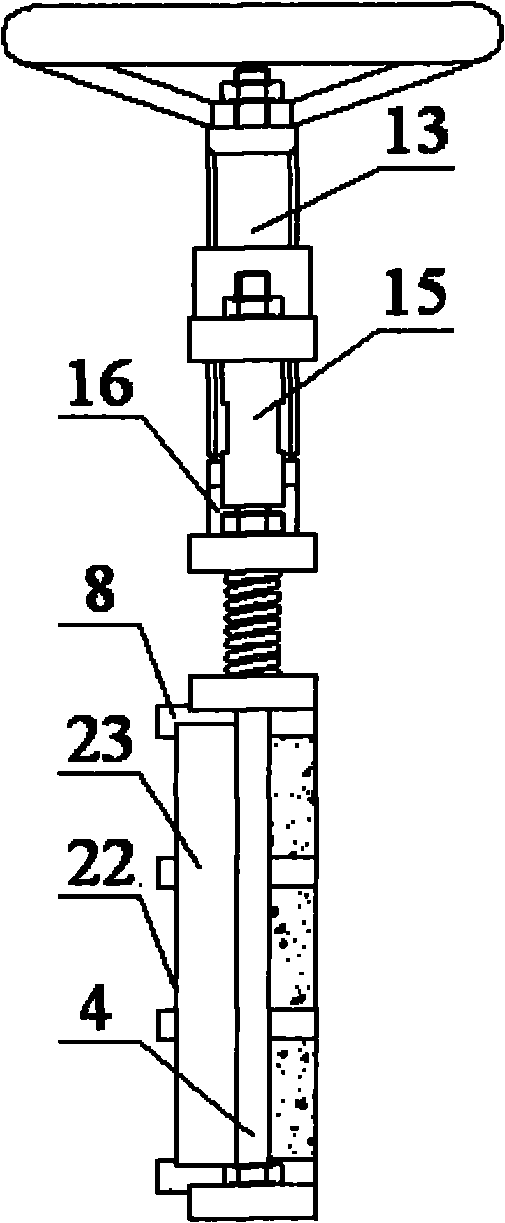

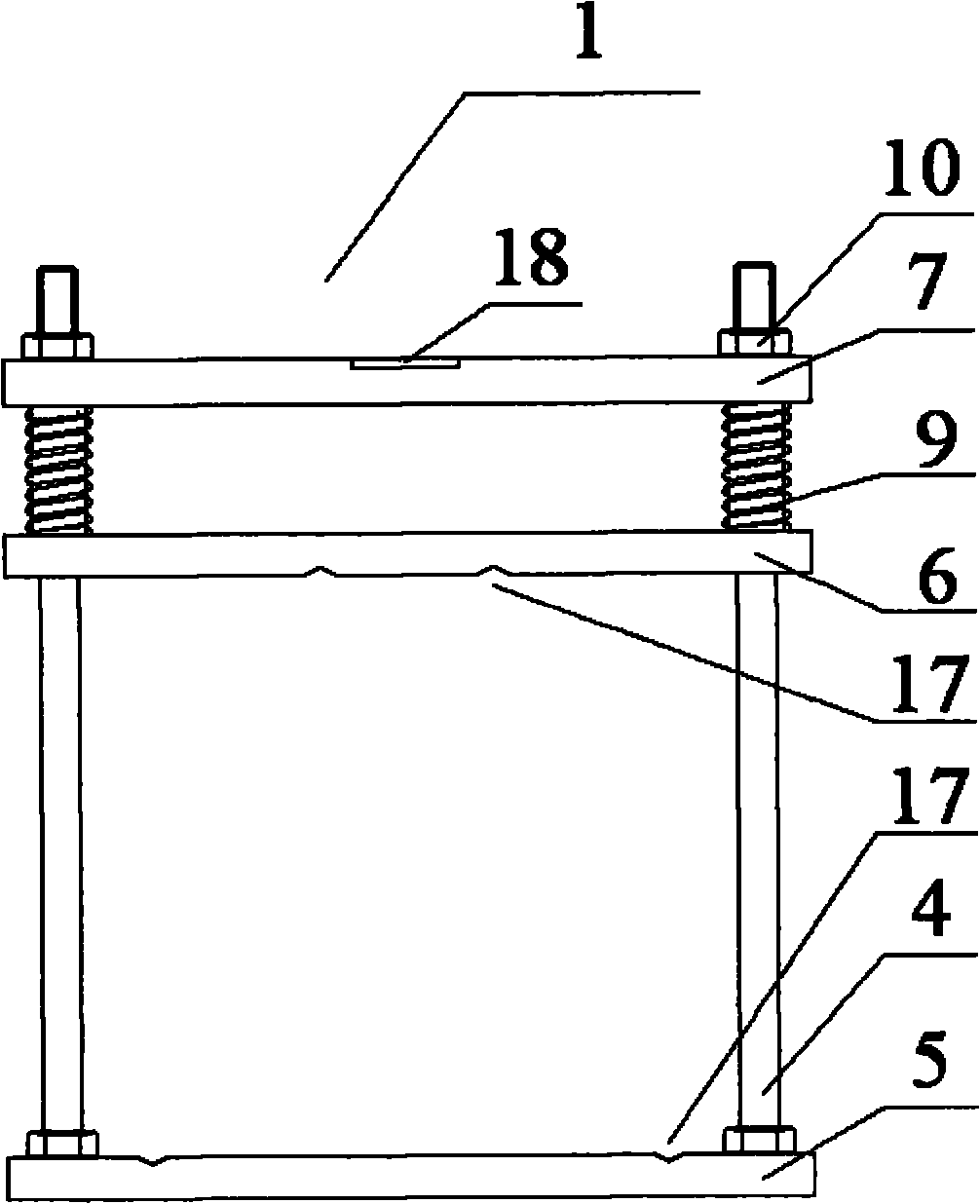

[0034] The self-positioning and detachable concrete durability test stress loading device of the present invention is composed of stress loading fixture 1, positioning fixture 2 and stress measurement and control fixture 3, which are used together to form a detachable structure with self-positioning function. Below in conjunction with accompanying drawing, connection mode and effect thereof of each part of the present invention are set forth as follows:

[0035] see Figure 1A and figure 2 As shown, the stress loading fixture 1 includes two uprights 4 , a lower pressing plate 5 , a middle pressing plate 6 , an upper pressing plate 7 , multiple rollers 8 and two springs 9 for applying constant stress to a concrete specimen 11 . Wherein, each column 4 lower end and the lower pressing plate 5 both sides are provided with supporting threads and screw holes, and the two are fixed with nuts 10 after being threaded; Pressing plate 6, spring 9 and upper pressing plate 7 pass through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com