Stabilized liquid enzyme compositions

一种液体组合物、肽化合物的技术,应用在洗涤剂组合物、酶稳定、酶等方向,能够解决枯草杆菌蛋白酶和其他酶稳定性降低、液体洗涤剂洗涤性能降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] The different peptide aldehydes were produced by custom peptide synthesis companies, all with >80% purity. Peptide aldehydes were dissolved in DMSO to a concentration of 10 mg / ml before use.

[0065] Prepare model liquid diluents for testing different stabilizers:

[0066] Detergent base:

[0067] components

%w / w

Sodium Alkyl Ethoxy Sulfate (C9-15, 2EO)

6.0

Sodium dodecyl benzene sulfonate

3.0

Sodium toluenesulfonate

3.0

2.0

Primary Alcohol Ethoxylates (C12-15, 7EO)

3.0

Primary Alcohol Ethoxylates (C12-15, 3EO)

2.5

0.5

Monopropylene Glycol

2.0

Trisodium Citrate Dihydrate

4.0

0.4

Deionized water

add up to 100%

[0068] pH adjusted to 8.5 with NaOH

[0069] A control detergent with enzyme was prepared:

[0070] Detergent A:

[0071] components

%w / w

...

Embodiment 2

[0078] The following control detergents with enzymes were prepared:

[0079] Detergent L:

[0080] components

%w / w

Detergent base from Example 1

98.5

Protease (Savinase 16.0LEX)

0.5

Lipase (Lipex 100L)

0.5

Amylase (Stainzyme 12L)

0.5

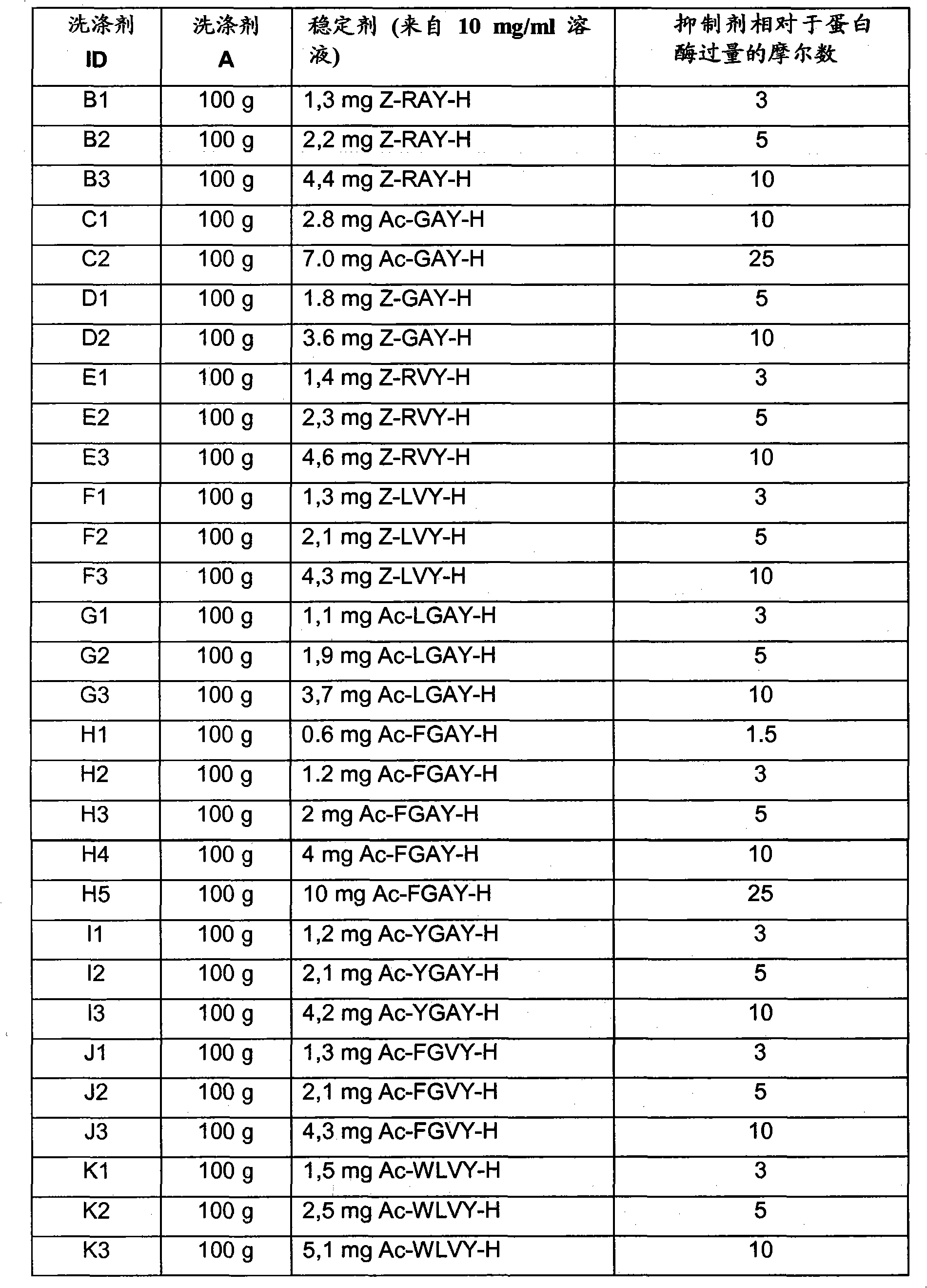

[0081] The following detergents with stabilizers according to the invention were prepared and standardized to 100 g of detergents:

[0082]

[0083] The detergents were placed in closed glasses at 25°C and 35°C. Residual lipase, amylase and protease activities were measured at different times (w = weeks) (by comparison with controls stored at -18°C) using standard enzymatic assays (by hydrolysis of N,N -Dimethylcasein to measure protease, lipase by hydrolysis of p-nitrophenyl valerate at 40°C, pH 7.7, and 4,6-ethylene-( G7) p-nitrophenyl-(G1)-α, D-maltoheptanoside (4,6-ethylene-(G7)p-nitrophenyl-(G1)-α, D-maltoheptasoid) to measure amylase).

[0084]

[0085] It can be...

Embodiment 3

[0087] Peptide aldehydes Z-GAF-H, Z-GAL-H and Z-GAY-H were produced by peptide synthesis, all with >80% purity. Peptide aldehydes were dissolved in DMSO to a concentration of 10 mg / ml before use.

[0088] The following detergent N with enzymes was prepared:

[0089] components

%w / w

Sodium Alkyl Ethoxy Sulfate (C9-15, 2EO)

20.0

Sodium toluenesulfonate

3.0

4.0

Primary Alcohol Ethoxylates (C12-15, 7EO)

2.5

Primary Alcohol Ethoxylates (C12-15, 3EO)

2.0

2.1

4.5

Trisodium Citrate Dihydrate

5.0

Deionized water

Add to 99%

pH adjusted to 8.0 with NaOH

Protease (Savinase 16.0LEX)

0.5

Lipase (Lipex 100L)

0.5

[0090]The following detergents with stabilizers according to the invention were prepared and standardized to 100 g of detergents:

[0091]

[0092] The detergent was placed in a clos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com