Method of preparing ginkgo protein superfine powders

A technology of ultrafine powder and ginkgo, which is applied in the field of preparation of ginkgo protein ultrafine powder, which can solve the problems of low extraction rate of ginkgo oil and affect the deep processing of ginkgo, and achieve the effect of maintaining the original quality and original flavor, maintaining no denaturation, and increasing the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0068] A preparation method of ginkgo protein superfine powder, comprising the following steps:

[0069] The first step, low-temperature drying: Freeze-dry the freshly collected ginkgo in autumn at -10°C to -50°C, for example, the temperature is selected as -20°C, -30°C, -40°C, then remove the shell and underwear, and dry the nuts Pulverize, rapid infrared measurement, obtain ginkgo coarse powder with water content weight percentage less than 6%, particle size in 10 mesh-50 mesh,

[0070] The second step, low-temperature wall breaking: at a temperature lower than 10°C, for example, -3°C, -5°C, -15°C, 0°C, 2°C, 5°C, 8°C, 9°C, the ginkgo Coarse powder adopts jet-type low-temperature jet mill (available in the market, Zhejiang Fengli Equipment Co., Ltd. DFJ-15 type) to break the wall and pulverize to obtain ginkgo superfine powder, and the jet mill classification wheel frequency is 20-60Hz, such as being selected as 30Hz, 40Hz , 50Hz, air pressure 0.8-1.5MPa, such as 0.9MPa, 1.0...

Embodiment 2

[0079] A preparation method of ginkgo protein superfine powder, comprising the following steps:

[0080] (1) Low-temperature drying: Freeze-dry the ginkgo fruits collected fresh every autumn at -10°C to -50°C for 6-50 hours, crush the shells with mechanical rollers, remove the shells and underwear, and crush the nuts into ginkgo Coarse powder, water content <6%, particle size between 10 mesh and 50 mesh,

[0081] (2) Low-temperature wall breaking: the low-temperature dried ginkgo coarse powder is broken and pulverized by a spray-type low-temperature airflow mill, the airflow mill grading wheel frequency is 20-60Hz, the temperature is <10°C, the air pressure is 0.8-1.5MPa, and the feeding speed is 1kg / h-3kg / h, crushing time 5-50min, the particle size of ginkgo superfine powder is 1-25μm, and the wall breaking rate is greater than 98%.

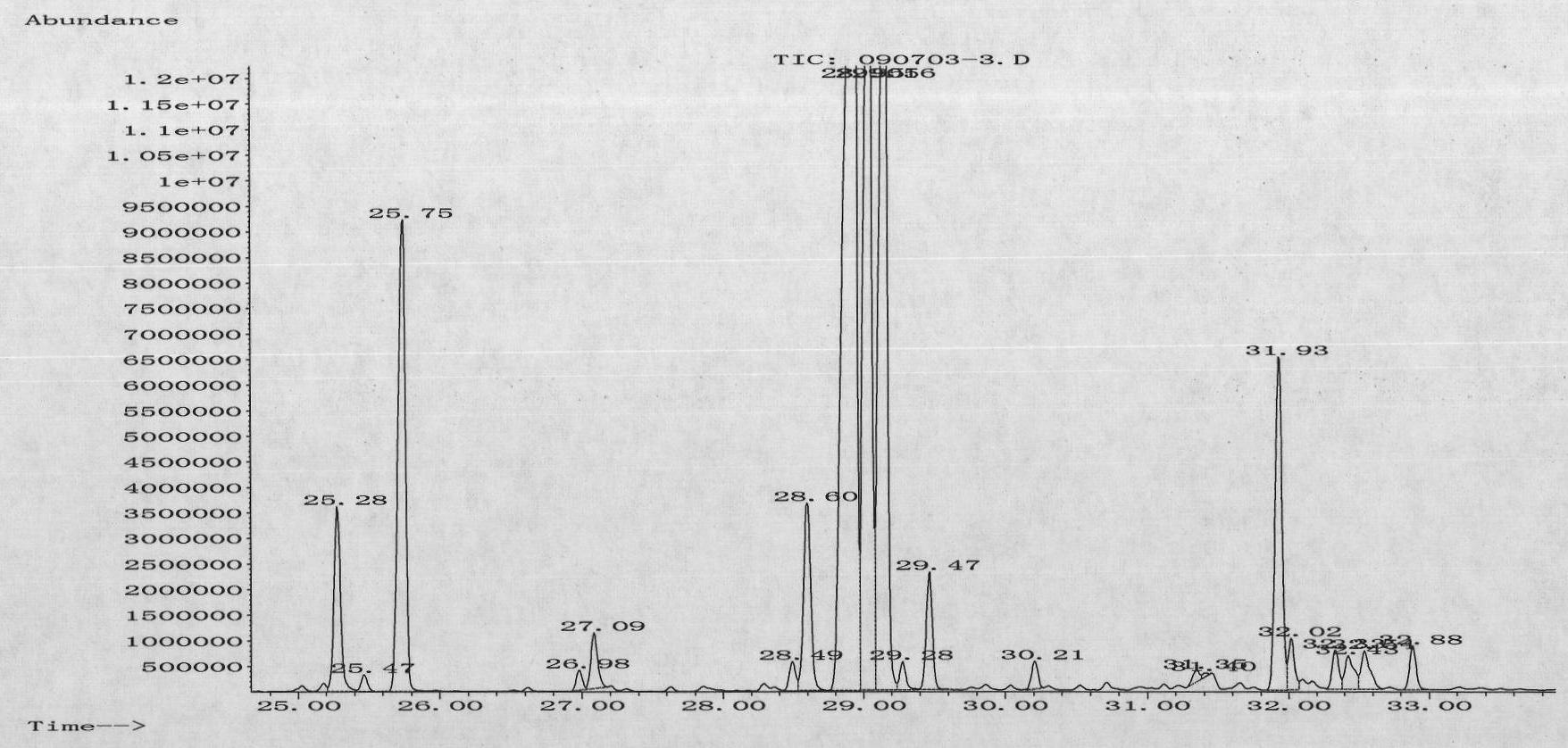

[0082] (3) Low-temperature degreasing: use CO 2 Supercritical extraction, extraction pressure 10-30MPa, extraction temperature 25-50°C, extra...

Embodiment 3

[0089] The preparation of embodiment 3 ginkgo superfine powder

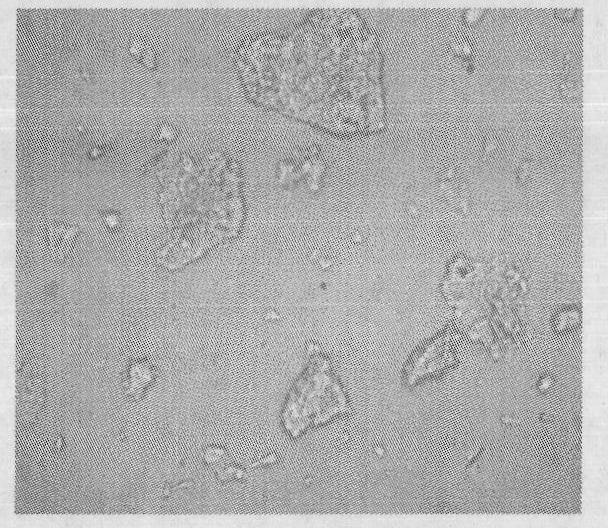

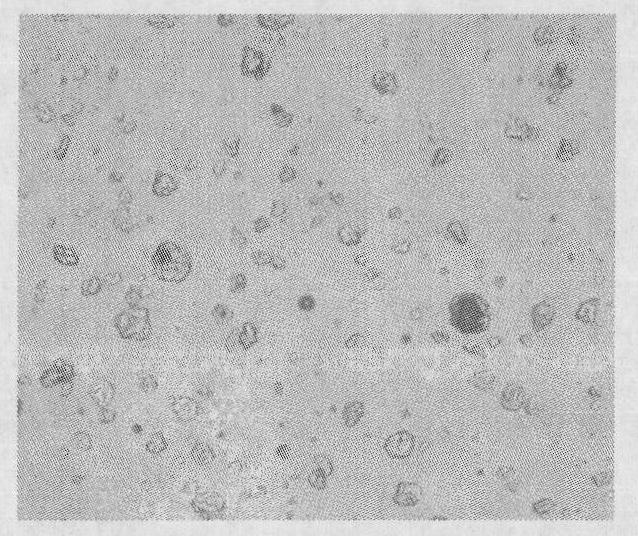

[0090] Collect seven varieties of ginkgo, including Dafozhi, Bianfozhi, Qixingguo, and longan, in Taixing, Jiangsu, remove the shells, and quickly measure the water content by infrared. The water content is between 50% and 65%. Quickly measure the water content to obtain dried ginkgo fruit with a water content of figure 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com