Polyurethane coating and preparation method thereof

A technology of polyurethane coatings and fatty acid esters, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems that coatings cannot actively degrade harmful gases, coating performance degradation, environmental pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

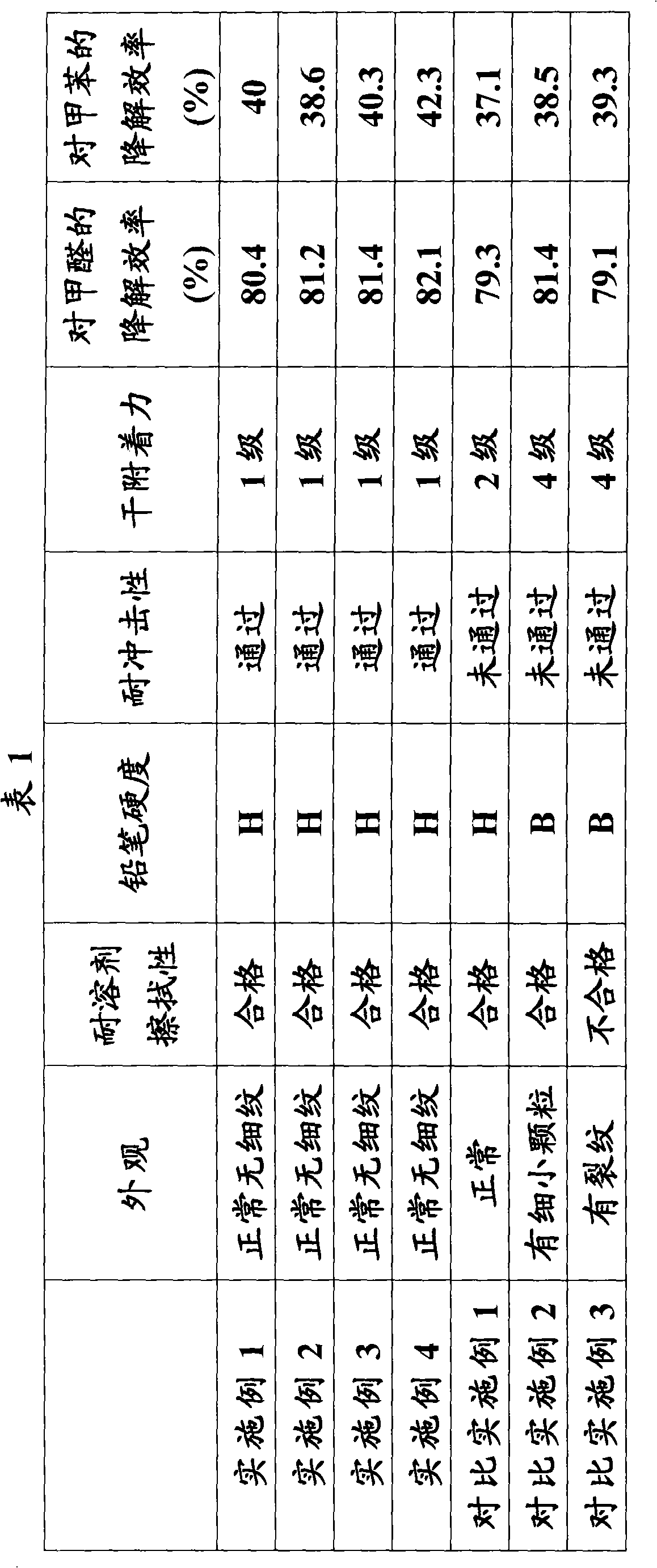

Examples

Embodiment 1

[0041] Accurately weigh 2.4 grams of nano-titanium dioxide particles with a particle size of 16-20nm, add them to 12.1 ml of methanol under stirring, continue stirring for about 20 minutes, and then add 0.07 grams of ethylene glycol fatty acid with a hydrophilic-lipophilic balance value of 3.6 Ester Emcol EL-50, ultrasonic treatment for 30 minutes, to obtain surface-modified nano titanium dioxide. With the nano-titanium dioxide dispersion of gained surface modification in methanol, 60 grams of hydroxyl acrylic resin (TB60018P type, Xiamen Kangdilong company), 12 grams of toluene diisocyanate and 30 milliliters of butanone and xylene (volume ratio is 3: 1) The mixed solvent is mixed to obtain the polyurethane coating of the present invention.

[0042] The coating obtained by the polyurethane coating in Example 1 is normally without fine lines, the solvent wiping resistance is qualified, the pencil hardness is H, the impact resistance test is passed, the dry adhesion is grade 1,...

Embodiment 2

[0044] Accurately weigh 3.1 grams of nano-titanium dioxide particles with a particle size of 45-50nm, add it to 11.8 milliliters of ethanol under stirring, continue to stir for about 20 minutes, then add 0.12 grams of polyoxyethylene sorbitol with a hydrophilic-lipophilic balance value of 4.0 Arias G-1727, a beeswax derivative, was sonicated for 1 hour, filtered, washed with 6 ml of ethanol, and dried under reduced pressure at a temperature of 60° C. for 24 hours to obtain 3.22 grams of surface-modified nano titanium dioxide. Nano titanium dioxide of gained surface modification, 62 grams of hydroxyl alkyd resins (number average molecular weight 250000, Dalian Boxiang Industry and Trade Co., Ltd.), 7.7 grams of toluene diisocyanate and 29 milliliters of butanone and xylene (volume ratio is 3: 1 ) mixed solvent to obtain the polyurethane coating of the present invention.

[0045] The coating obtained by the polyurethane coating in Example 2 is normally free of fine lines, the so...

Embodiment 3

[0047] Accurately weigh 3.48 grams of nano-titanium dioxide particles with a particle size of 70-80nm, add them to 26.6 milliliters of isopropanol under stirring, continue stirring for about 20 minutes, and then add 0.21 grams of diethylene glycol with a hydrophilic-lipophilic balance value of 4.7 Alcohol fatty acid ester Emcol DO-50, sonicated for 2 hours, filtered, washed with 13 ml of isopropanol, and dried under reduced pressure at 60° C. for 24 hours to obtain 3.69 grams of surface-modified nano titanium dioxide. Nano titanium dioxide of gained surface modification, 58 grams of polyester polyols (100 types, Liaoyang Dongchen Polyurethane Co., Ltd.), 13.8 grams of diphenylmethane diisocyanate and 28 milliliters of butanone and xylene (volume ratio is 3: 1 ) mixed solvent to obtain the polyurethane coating of the present invention.

[0048] The coating obtained by the polyurethane coating of Example 3 is normally without fine lines, the solvent wiping resistance is qualifie...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com