Ladle slag roughing vibration detection device and method

A vibration detection and vibration signal technology, applied in the configuration of indicating equipment/measuring equipment, manufacturing tools, casting equipment, etc., can solve the problems of high rigidity of the operating arm, the impact of the large turntable, and the heavy weight, and achieve considerable economic benefits. , the effect of increasing the signal-to-noise ratio and increasing the signal energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The embodiments of the present invention will be described in detail below with reference to the accompanying drawings, but the present invention can be implemented in many different ways defined and covered by the claims. The same components are denoted by the same reference numerals in the drawings.

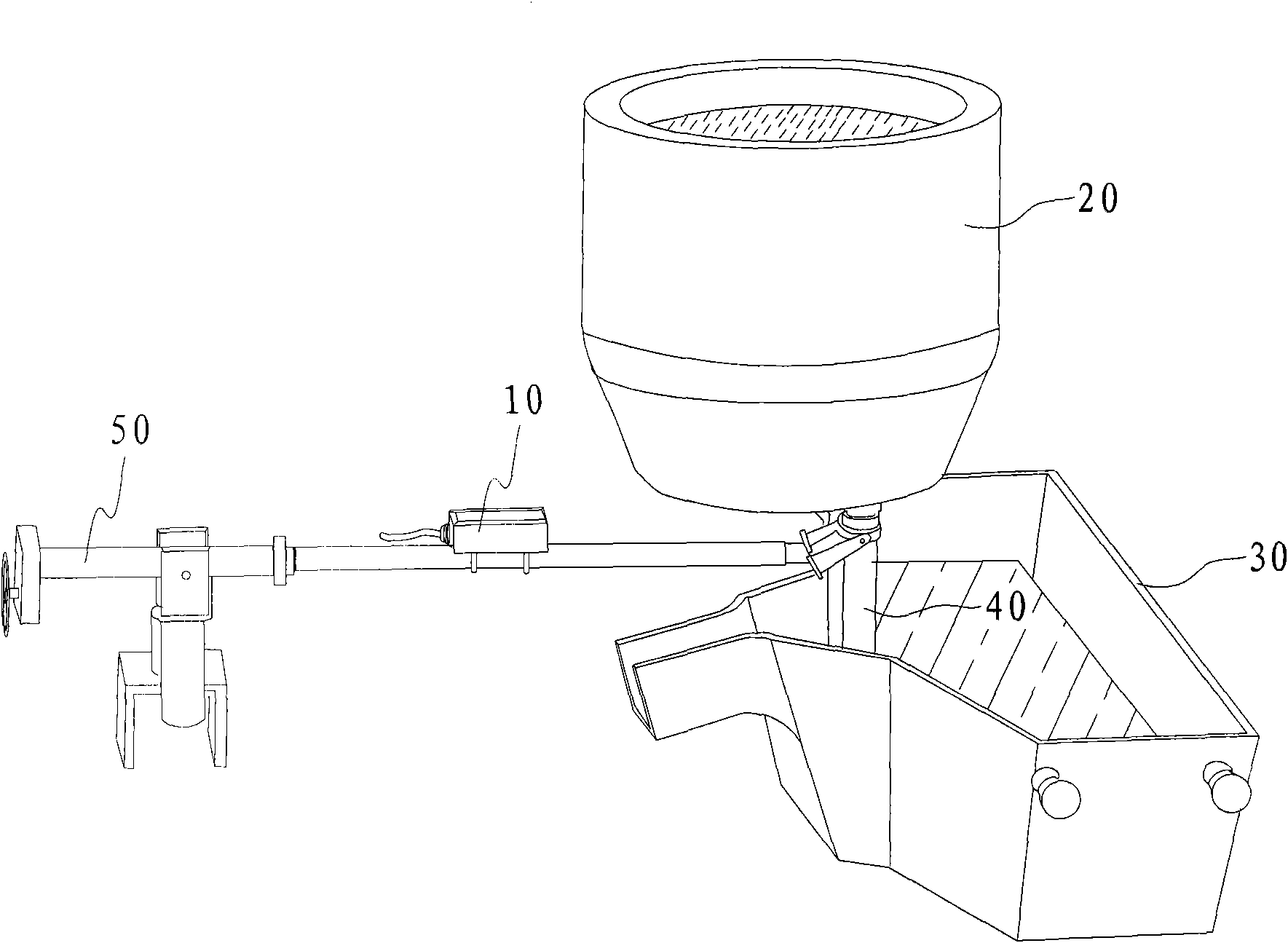

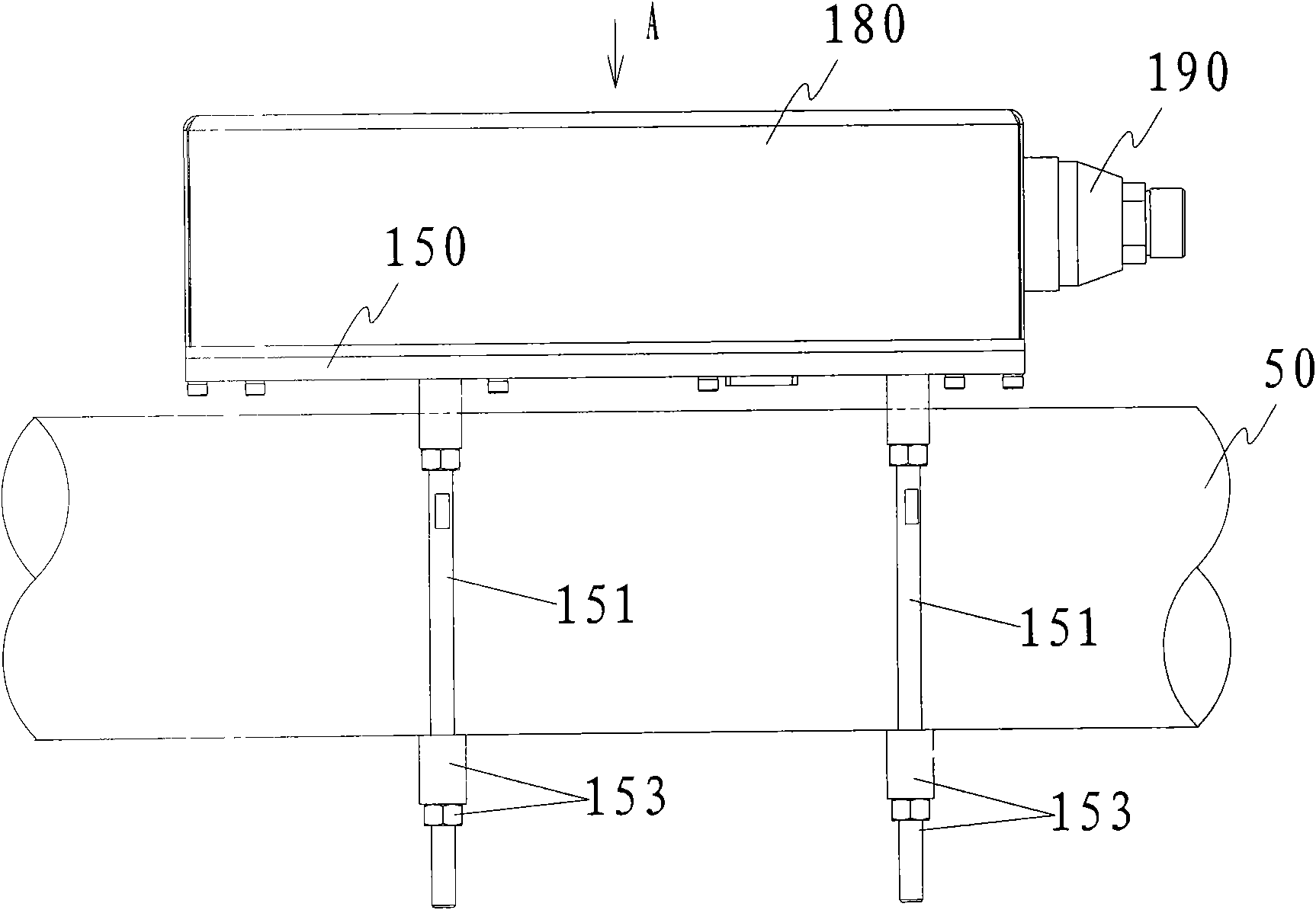

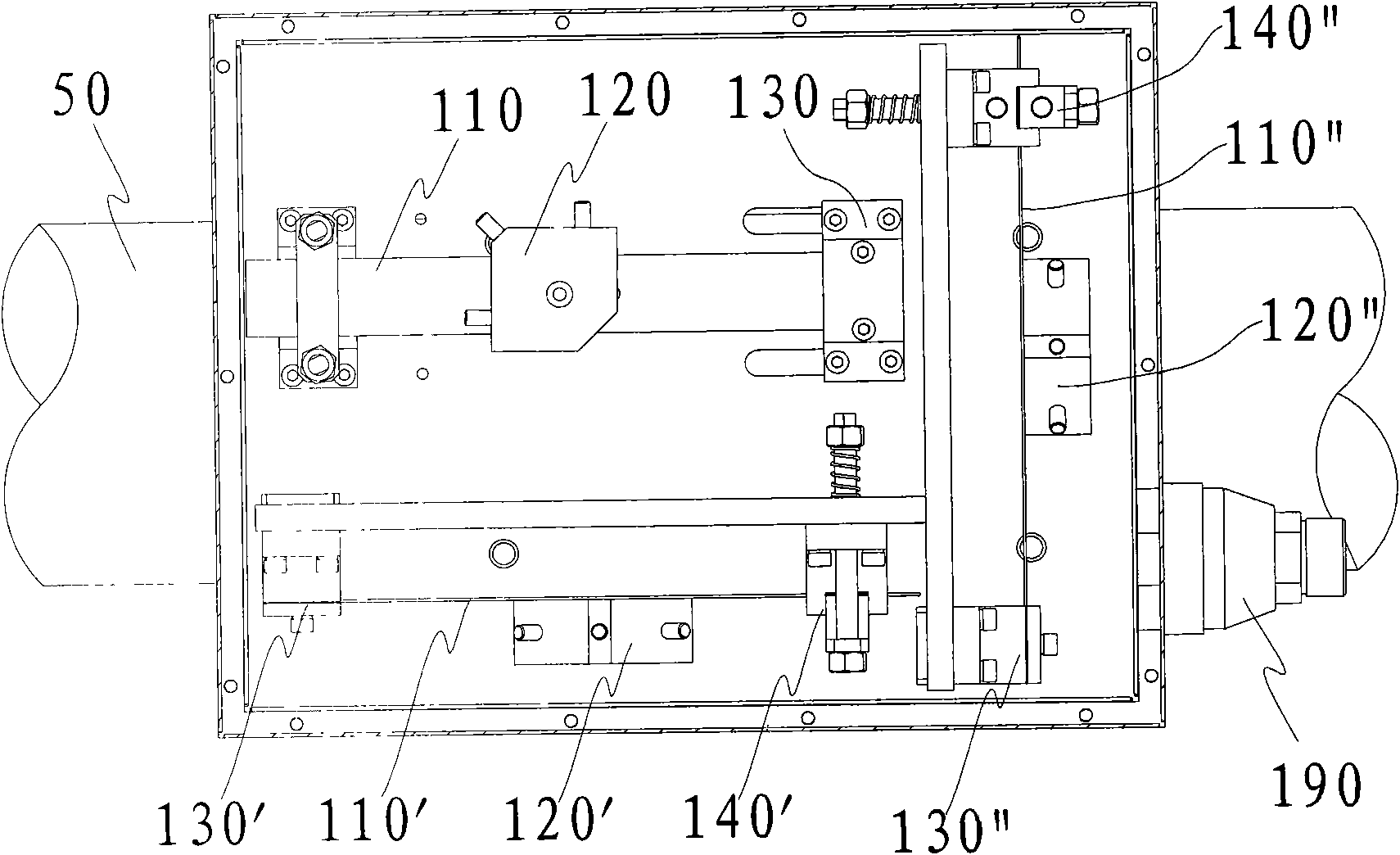

[0041]figure 1 A schematic diagram showing the application of the ladle slag vibration detection device according to the present invention to the ladle slag prediction, figure 2 It shows a schematic diagram of a ladle slag vibration detection device fixed to an operating arm according to a preferred embodiment of the present invention. Such as figure 1 and figure 2 As shown, in the continuous casting process, molten steel flows into the tundish 30 from the ladle 20 through the shroud 40, and the shroud 40 is inserted into the tundish 30, and the operating arm 50 of the steel plant is connected to the shroud 10 of the ladle 20. A vibration detection device 10 is inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com