Method for forming asymmetrical transistor

A transistor and asymmetric technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve problems such as increasing cost investment, achieve the effect of reducing capital investment and improving process window

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The inventors of the present invention have found that the existing process for forming pocket regions in transistors of asymmetric memory cells includes forming a separate photoresist pattern that exposes the source region / drain region, using the photoresist pattern as a mask , perform ion implantation to form a pocket area, the above-mentioned process adds an ion implantation process to the conventional transistor manufacturing process, needs to add a mask plate required for the ion implantation process, and adopts the corresponding photolithography process, the whole process adds additional Expenses are invested and the process time is extended.

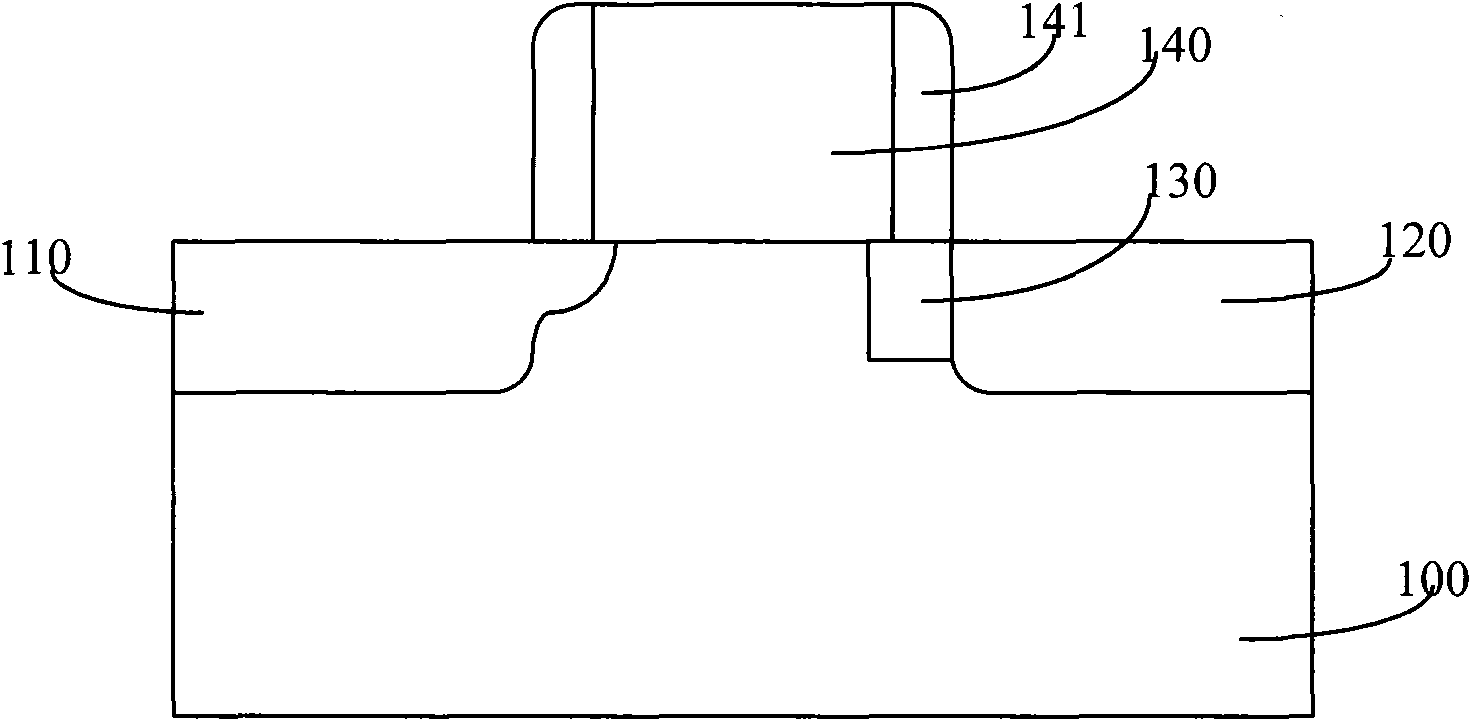

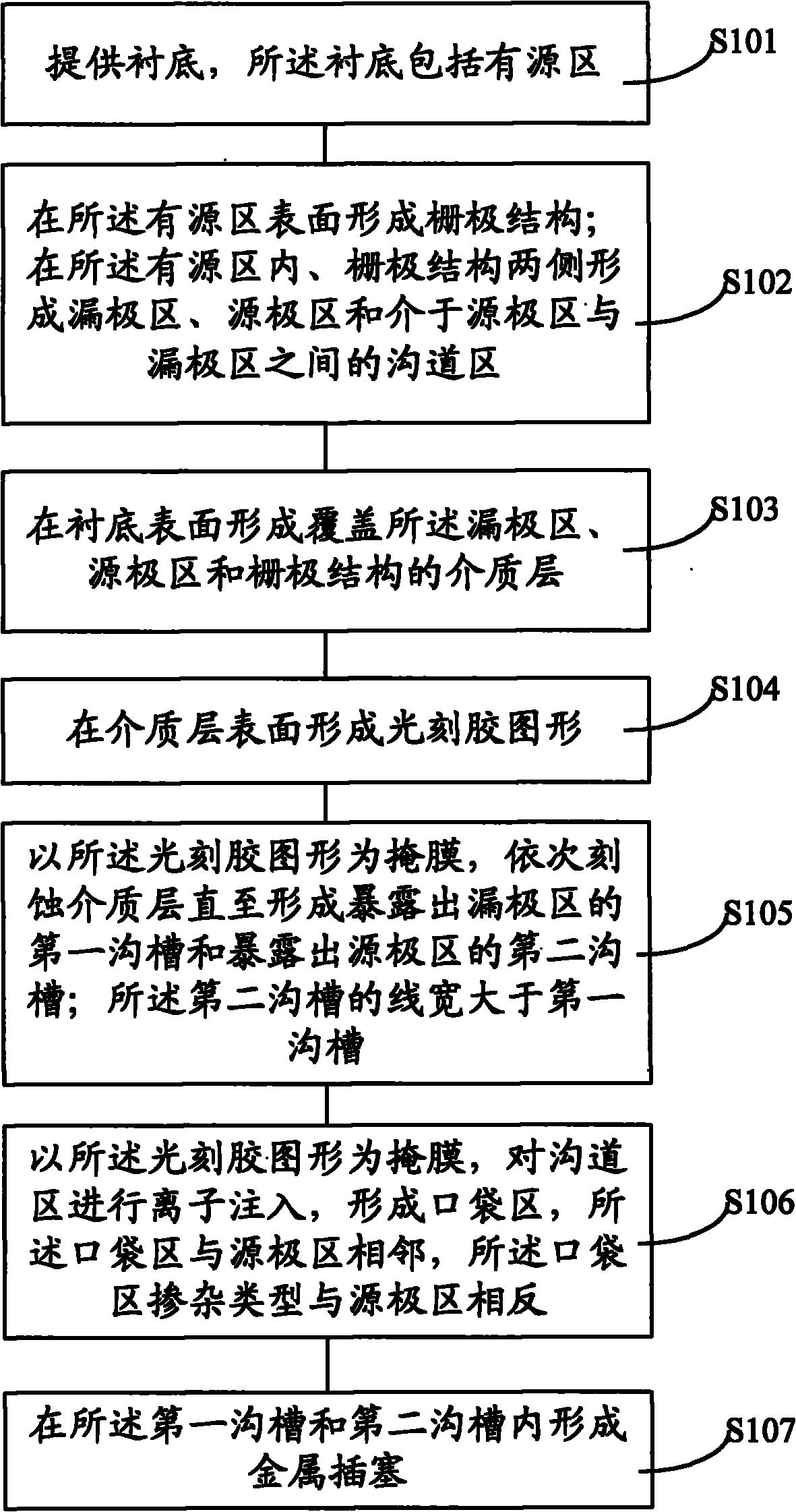

[0017] For this reason, the present invention provides a kind of forming method of asymmetric transistor, its flow process is as follows figure 2 As shown, it specifically includes the following steps:

[0018] Step S101, providing a substrate, the substrate including an active region;

[0019] Step S102, forming a gate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com