Device for chemical liquid spraying treatment of round lamellar object

A flake-like, chemical liquid technology, applied in the direction of injection devices, semiconductor/solid device manufacturing, electrical components, etc., to achieve the effect of avoiding cross-contamination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

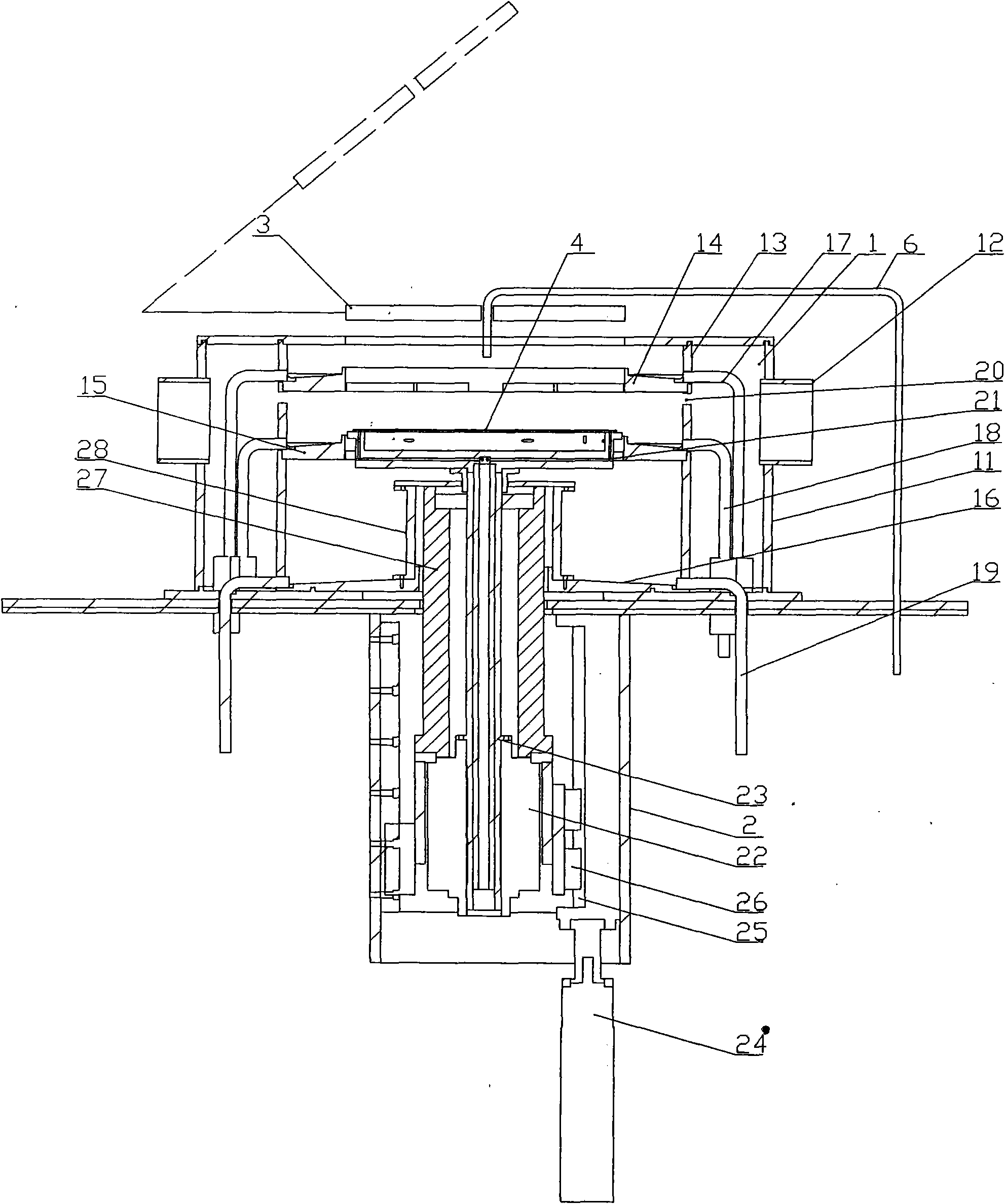

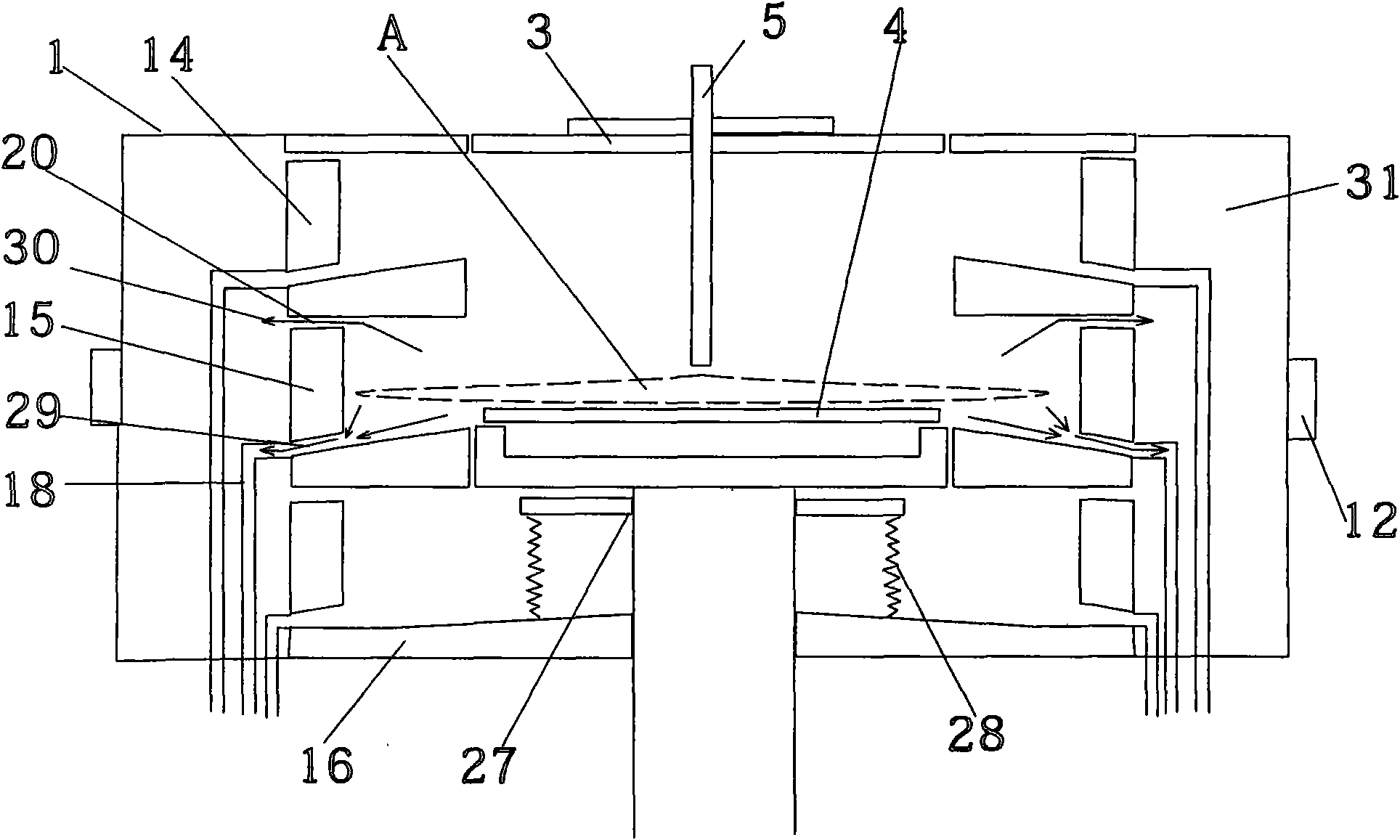

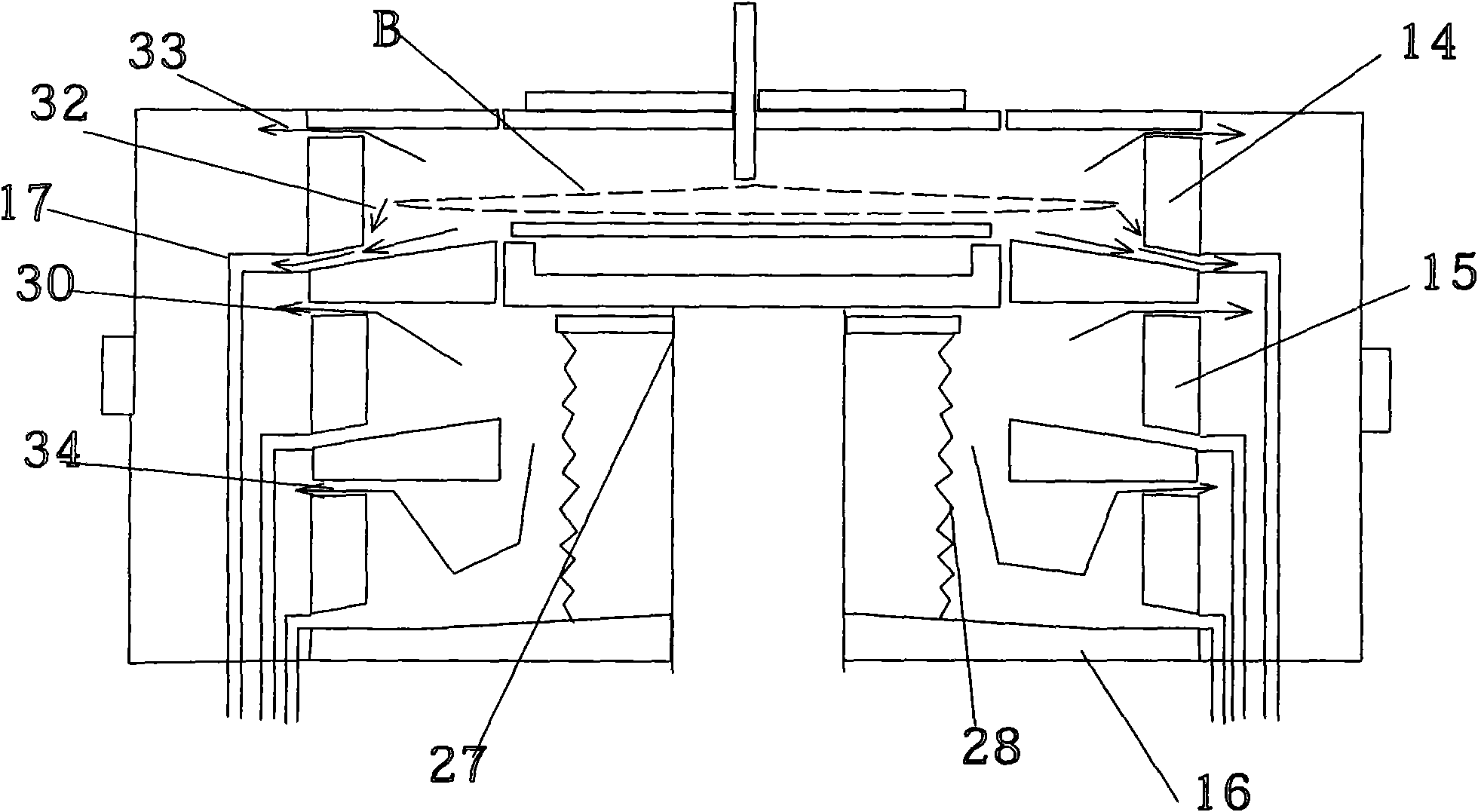

[0024] Such as figure 1 As shown, the entire inventive device includes a circular processing chamber 1, a silicon wafer rotation and lifting mechanism 2 and a movable cover plate 3. The circular processing chamber 1 has an outer layer side wall 11 and an inner layer side wall 13 arranged radially. The layer side wall 11 and the inner layer side wall 13 form a double-layer hollow structure. The inner layer side wall is composed of two or more layers of similarly shaped liquid collection ring I14, collection ring II15 and bottom collection ring 16. The collection ring I14 The collection circle II15 and the bottom collection circle 16 are all concave structures with holes in the center, and the drain pipes I17, II18 and III19 are respectively located at the bottom of the collection circle I14, the collection circle II15 and the bottom collection circle 16, There is an exhaust slit 20 between two adjacent collection rings, and an exhaust pipe 12 is opened on the outer side wall 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com