Preparation method of coal ash-based sound-absorbing material

A technology of sound-absorbing materials and fly ash, which is applied in the field of waste treatment and disposal in the energy industry, and can solve problems such as waste of resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

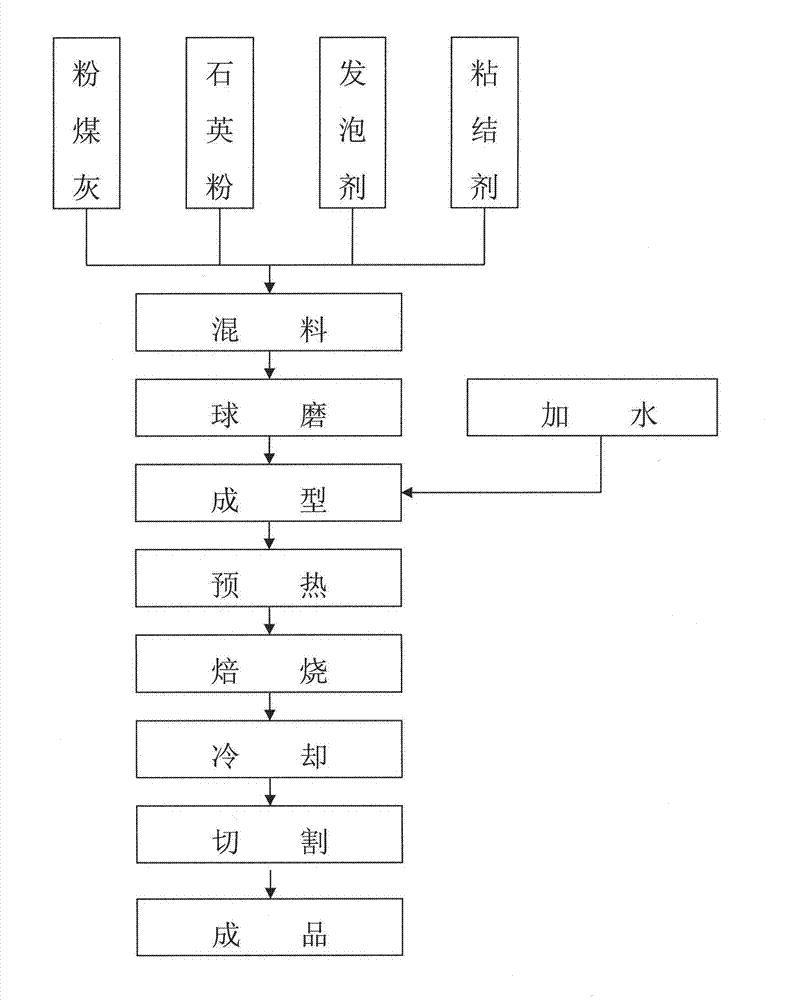

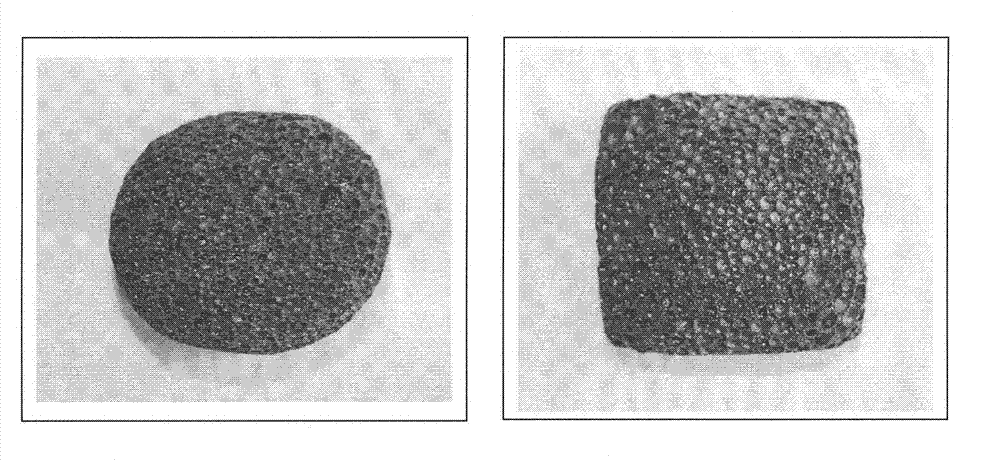

[0010] according to figure 1 As shown, the fly ash, quartz powder, special foaming agent and activator are dried, and 50% of fly ash, 20% of quartz powder, 20% of foaming agent, and 10% of activator are mixed according to the mass fraction Put it into a ball mill, and grind it to below 200 mesh; add 10% water to the mixer and mix it evenly; put the evenly mixed powder into a steel mold and press it into a machine, and the molding pressure is 10MPa; The good green body is fired in the muffle furnace. Dry at 105°C for 30 minutes, then heat from 105°C to 800°C at a speed of 17.4°C / min, then raise the temperature to 1080°C at a speed of 9.5°C / min and keep it for 20 minutes. Take it out of the furnace and let it cool naturally. Cut the cooled porous material into required size as required. The photo of the prepared fly ash porous sound-absorbing material is shown in figure 2 , the density of the sound-absorbing material is 450kg / m 3 , the compressive strength is 1.5MPa, and t...

Embodiment 2

[0012] Dry the fly ash, foaming agent and activator, add 70% of fly ash, 20% of rice husk ash, and 10% of cement into the ball mill according to the mass fraction; Add 10% water in the mixer and stir evenly; put the evenly stirred powder into a steel mold and press it into a machine, and the molding pressure is 10MPa; put the formed green body into a muffle furnace for firing. Dry at 105°C for 30 minutes, then heat from 105°C to 800°C at a rate of 17.4°C / min, then raise the temperature to 1090°C at a rate of 9.5°C / min for 20 minutes, and then wait for the furnace temperature to drop to 500°C from Take it out of the muffle furnace and let it cool naturally. Cut the cooled porous material into required size as required. The density of the prepared fly ash porous material is 400kg / m 3 , the compressive strength is 6MPa, and the porosity is 80%.

Embodiment 3

[0014] The specific process includes: (1) Mix fly ash, quartz powder, self-made special foaming agent, activator and adhesive, dry them evenly, add them into a ball mill and mill them below 200 mesh, and the proportion of ingredients is (by weight): Fly ash 50kg, quartz powder 5kg, self-made foaming agent 10kg, self-made activator and binder 10kg. (2) Add 10% water to the ball-milled powder in the mixer and stir evenly. (3) Put the evenly stirred powder into a steel mold and press it into a machine, and the molding pressure is 5 MPa. (4) Put the shaped green body into the muffle furnace for firing, preheating stage: dry at 105°C for 30 minutes to remove moisture in the green body; heating stage: heat up to 1080°C in 60 minutes, and Keep the temperature for 30 minutes at the firing temperature; cooling stage: the fired porous material is cooled to 500°C in the furnace, then taken out from the muffle furnace, and cooled naturally. (5) The annealed porous material is cut and pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com