Steel for petroleum casing pipe and manufacture method thereof

A technology of oil casing and manufacturing method, applied in casing, drill pipe, earthwork drilling and other directions, can solve the problems of high alloy cost and single alloy composition design system, so as to reduce alloy cost, improve market competitiveness, reduce The effect of market risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Process route: molten iron pretreatment → converter steelmaking → LF furnace refining → slab casting → billet finishing → storage, inspection → heating furnace heating → controlled rolling → controlled cooling → coiling → inspection and storage.

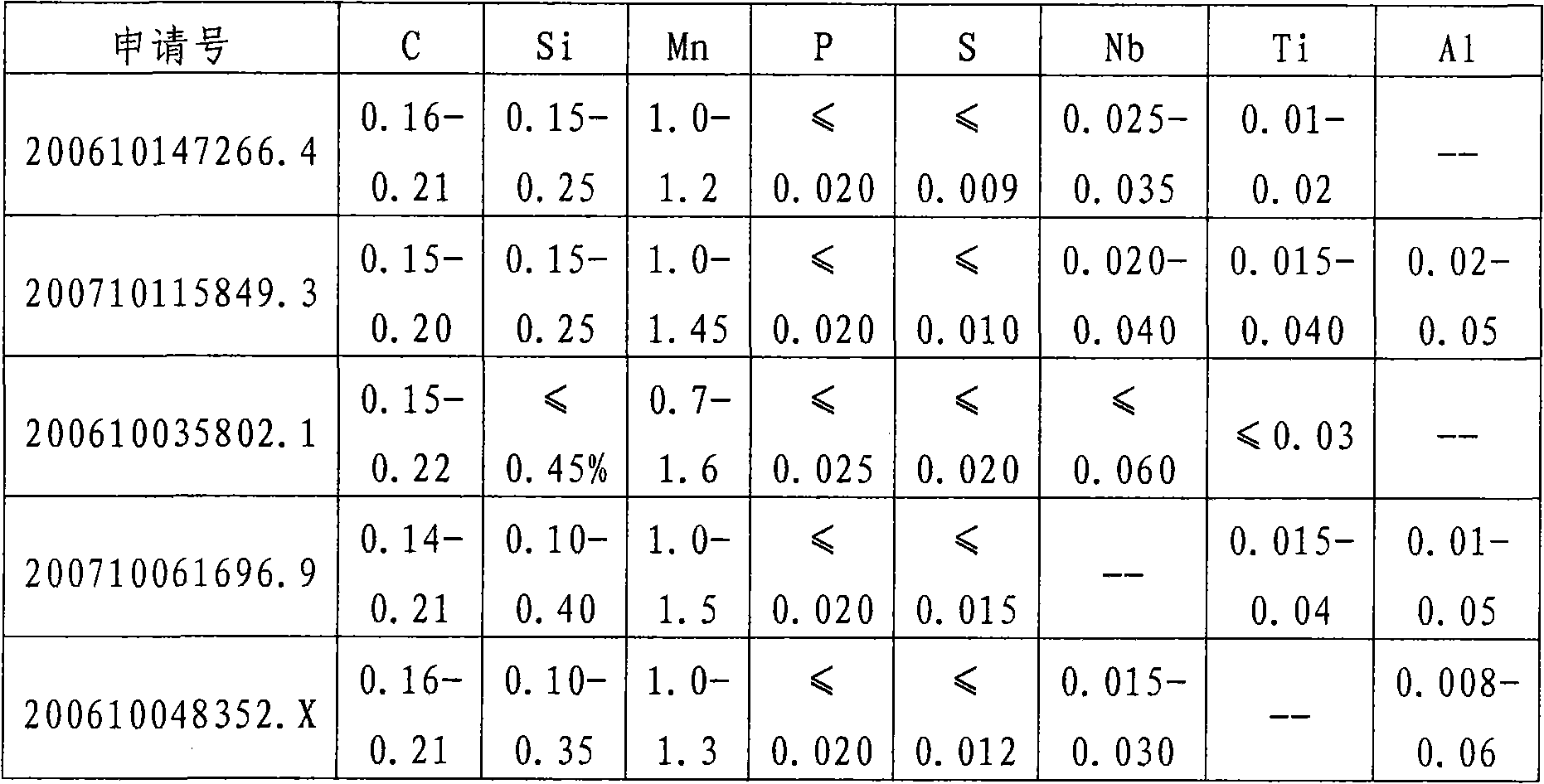

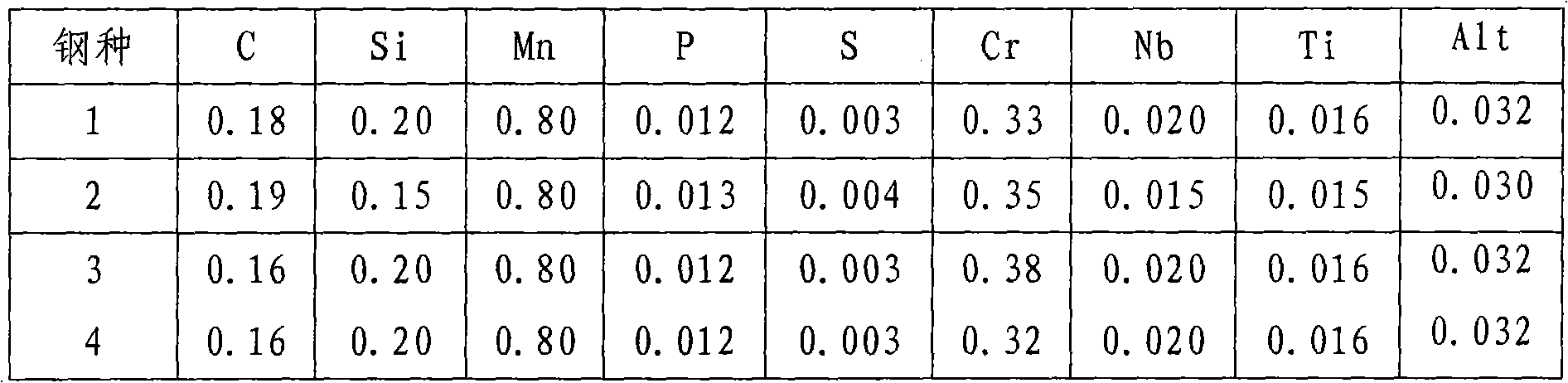

[0034] The actual smelting chemical composition is shown in Table 2, the specific rolling process parameters are shown in Table 3, and Table 4 is the test results of mechanical properties.

[0035] Table 2. Chemical composition of hot rolled steel coil for J55 containing Cr oil casing, wt%

[0036]

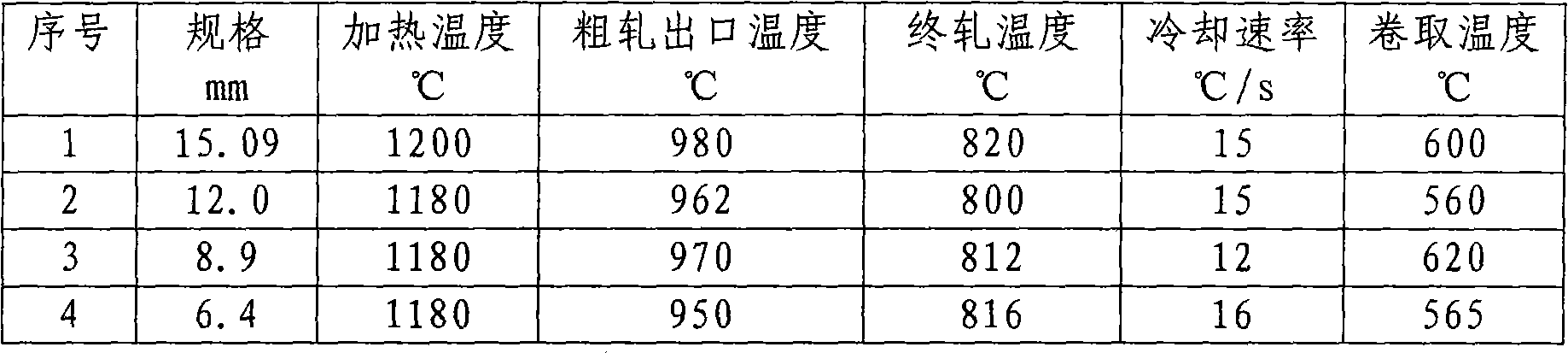

[0037] Table 3. Coil rolling process parameters of hot rolled steel for J55 containing Cr oil casing

[0038]

[0039] Table 4. Mechanical properties test results of hot-rolled steel coils for Cr-containing oil casing J55

[0040]

[0041] The metallographic structure of the hot-rolled steel coil containing Cr for petroleum casing J55 produced by the invention is ferrite + pearlite structure, the grain size is 11 grades,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com