Electric furnace waste heat recycling and dedusting device

A technology of waste heat recovery and dust removal device, applied in furnaces, waste heat treatment, furnace components, etc., can solve the problems of complicated flue gas cooling and cooling system, increasing flue gas water content, and easy hardening of dust removal bags, so as to avoid equipment blockage and low temperature. Corrosion of sulfur dioxide, reduction of energy consumption for system operation, and reduction of ash discharge operating points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

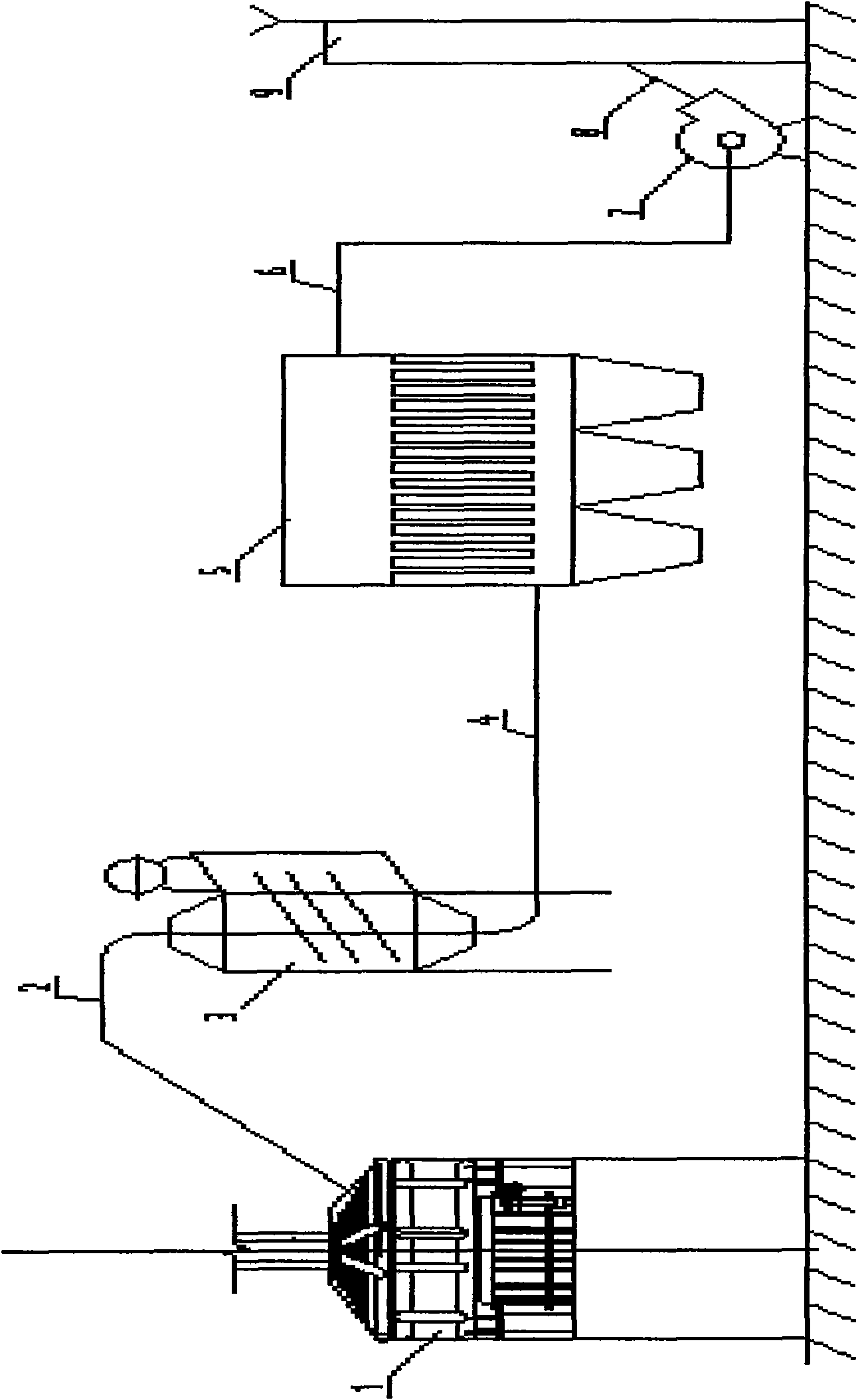

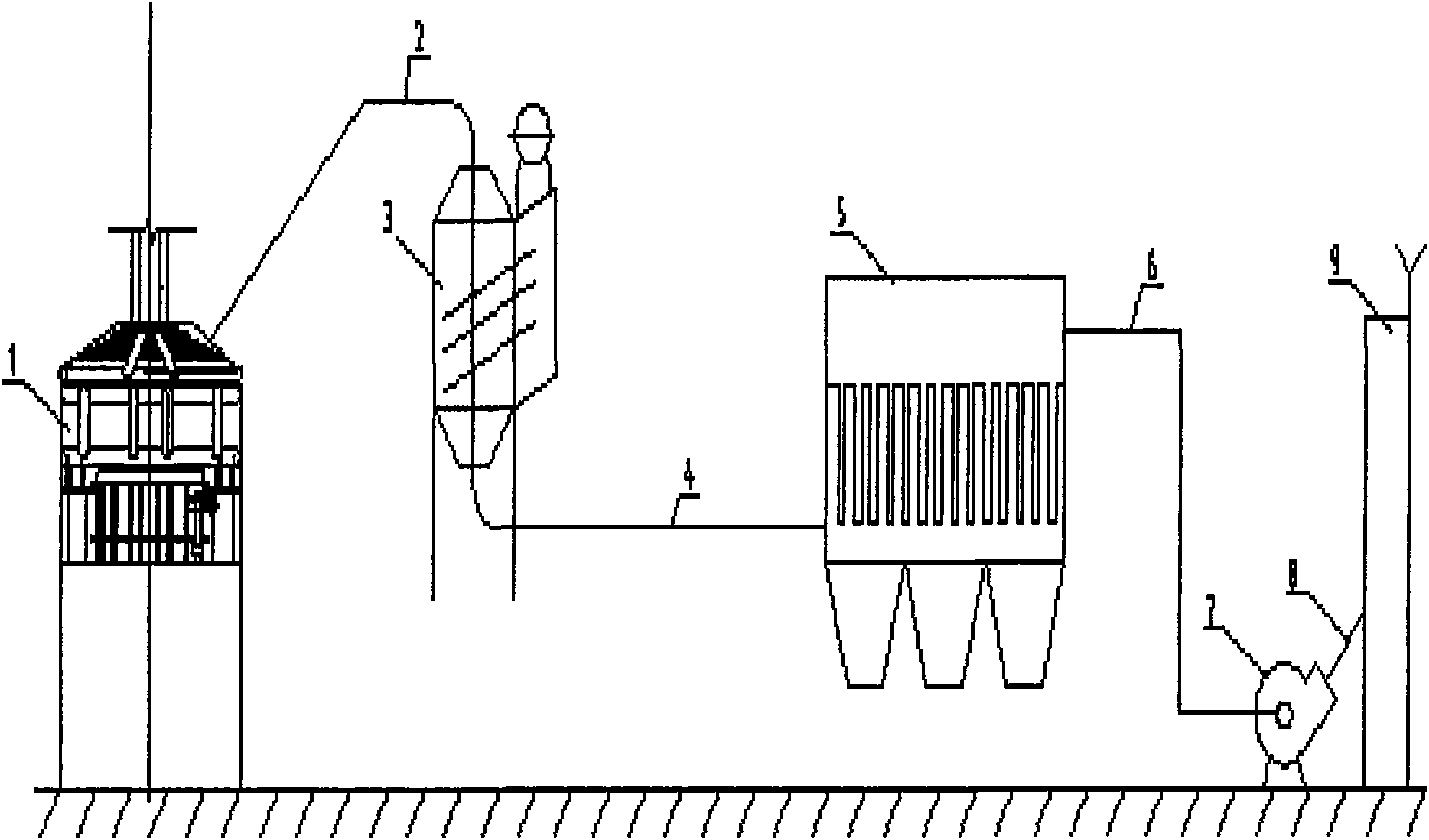

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

[0013] The present invention comprises the deduster 5, main blower 7, gas generating device 9 that are connected in sequence, and it also comprises heat pipe steam generator 3, and described heat pipe steam generator connects fully enclosed electric furnace 1 through gas pipeline (1) 2, and described heat pipe The output end of the steam generator is connected to the dust collector 5 through the pipe (2) 4 . The outlet connection pipe (3) 6 of the dust collector sends the purified combustible gas to the power generation device 9 . The heat pipe steam generator is composed of heat exchange tube bundles. The heat receiving section of the heat exchange tube bundle is placed in the high temperature flue, the flue gas traverses the heat pipe heating section, and the heat release section of the heat pipe element is inserted in the water-steam system.

[0014] The dust colle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com