Method for manufacturing negative temperature coefficient (NTC) thermosensitive chip for high-precision temperature sensor

A technology of temperature sensor and manufacturing method, which is applied to thermometers, thermometers and instruments using electric/magnetic elements directly sensitive to heat, and can solve problems such as aging, electrical performance drift, and poor stability between semiconductor ceramics and metal electrodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

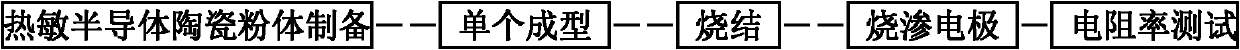

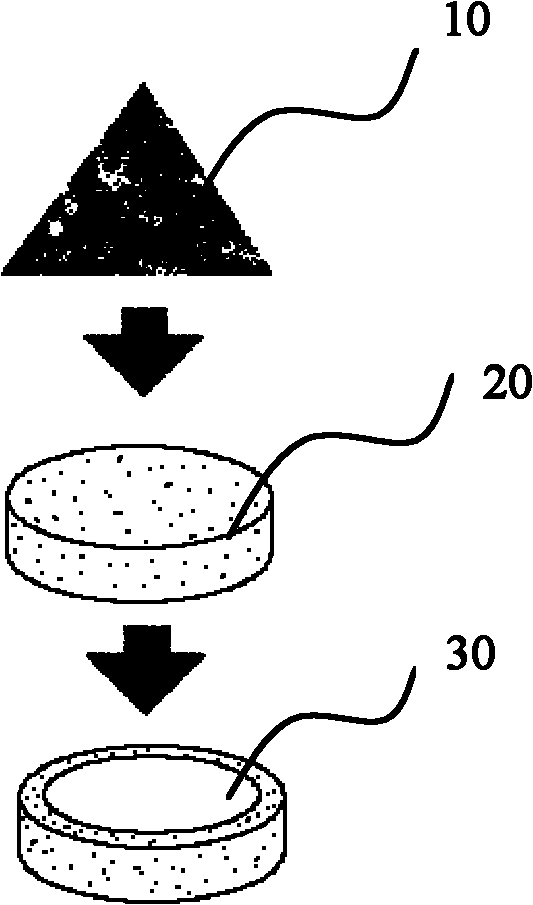

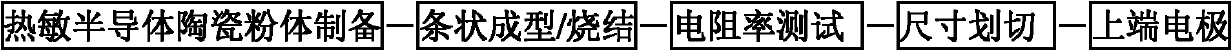

[0050] This embodiment is illustrated by taking a disc-type NTC thermistor with a resistance value of 10Ω and a diameter of 9mm as an example: image 3 , Figure 4 As shown, the production steps are: (1) preparation of NTC heat-sensitive semiconductor ceramic powder; (2) strip molding / sintering; (3) glass packaging; (4) resistivity test; (5) size cutting; ( 6) Upper electrode.

[0051] specifically is:

[0052] 1. Preparation of NTC thermosensitive semiconductor ceramic powder 1 (preparation of NTC material with resistivity ρ=19.23Ω.cm)

[0053] Physical method (ball milling method) heat-sensitive semiconductor ceramic powder, its process is: batching (according to a specific formula) - ball milling - discharge - drying - sieving - pre-calcination - grinding - drying - sieving - powder for later use.

[0054] 2. Strip molding / sintering: the prepared NTC heat-sensitive ceramic powder 1 is placed in a mixing tank according to the weight ratio of porcelain powder: PVA binder = ...

Embodiment 2

[0066] This embodiment is illustrated by taking the manufacturing method of 0603~10KΩB(25 / 50)=3435K chip NTC thermistor as an example: it is basically the same as Embodiment 1, except that:

[0067] (1) The preparation method of the NTC thermosensitive semiconductor ceramic powder is made by the chemical method of sol-gel, and the specific steps are: preparation of sol-gelling-gel drying-calcination-NTC thermosensitive semiconductor Ceramic powder is available for use.

[0068] (2) Strip forming / sintering:

[0069] NTC thermosensitive ceramic rod (rod) isostatic pressing method:

[0070] Put the prepared NTC heat-sensitive ceramic powder in the rubber mold, loosely pack and vibrate;

[0071] Place it in an isostatic press, press with a pressure of 300-400Mpa for 30 minutes, release the pressure, and take it out from the mold;

[0072] High-temperature sintering: The pressed green ceramic ingot is slowly heated (1°C / min) to 1200±50°C in a high-temperature sintering furnace, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resistance | aaaaa | aaaaa |

| Film diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com