Method for measuring transmission loss of optical element

A technology of optical components and measurement methods, used in transmittance measurement, testing optical performance and other directions, can solve the problem of difficult optical component measurement, achieve high signal-to-noise ratio, and improve measurement accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

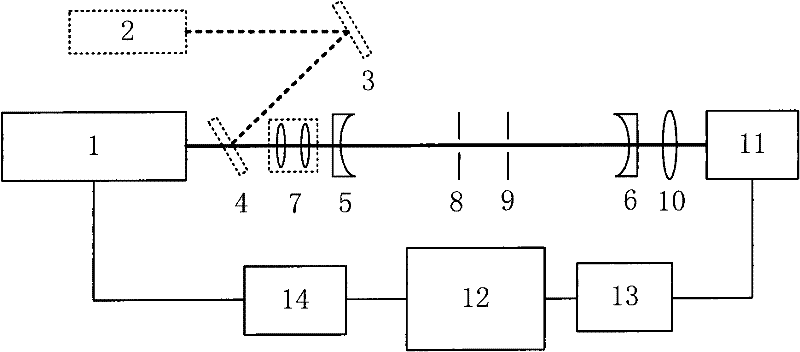

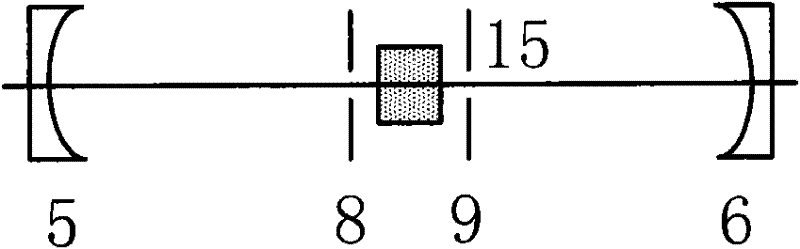

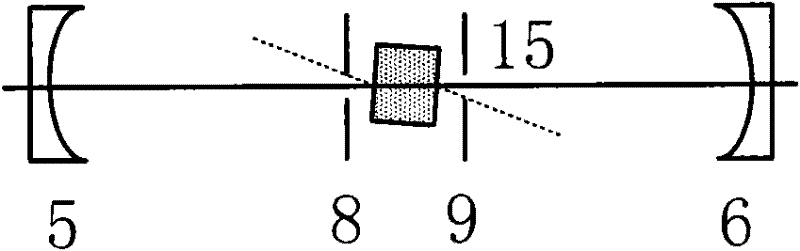

[0042] Attached below figure 1 The described system describes the method for measuring transmission loss of an optical element of the present invention. figure 1 Middle: 1 is the light source, 2 is the visible auxiliary light source, 3 is the reflector, 4 is the double-beam beam splitter, 5 and 6 are the plano-concave high-reflection cavity mirror, 7 is the mode matching lens group, 8 and 9 are the iris diaphragm 10 is a focusing lens, 11 is a photodetector, 12 is a computer, 13 is a data acquisition card, and 14 is a function generation card. Among the figures, thick lines are optical paths, and thin lines are connection lines.

[0043] The light source 1 is a continuous semiconductor laser, and the semiconductor laser adopts a 100Hz square wave modulation output; two identical flat-concave high-reflection cavity mirrors 5 and 6 have a reflectivity greater than 99% at the wavelength of the laser, and the optical resonator is a stable cavity or a confocal cavity. The length L...

PUM

| Property | Measurement | Unit |

|---|---|---|

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com