Wire bonding apparatus

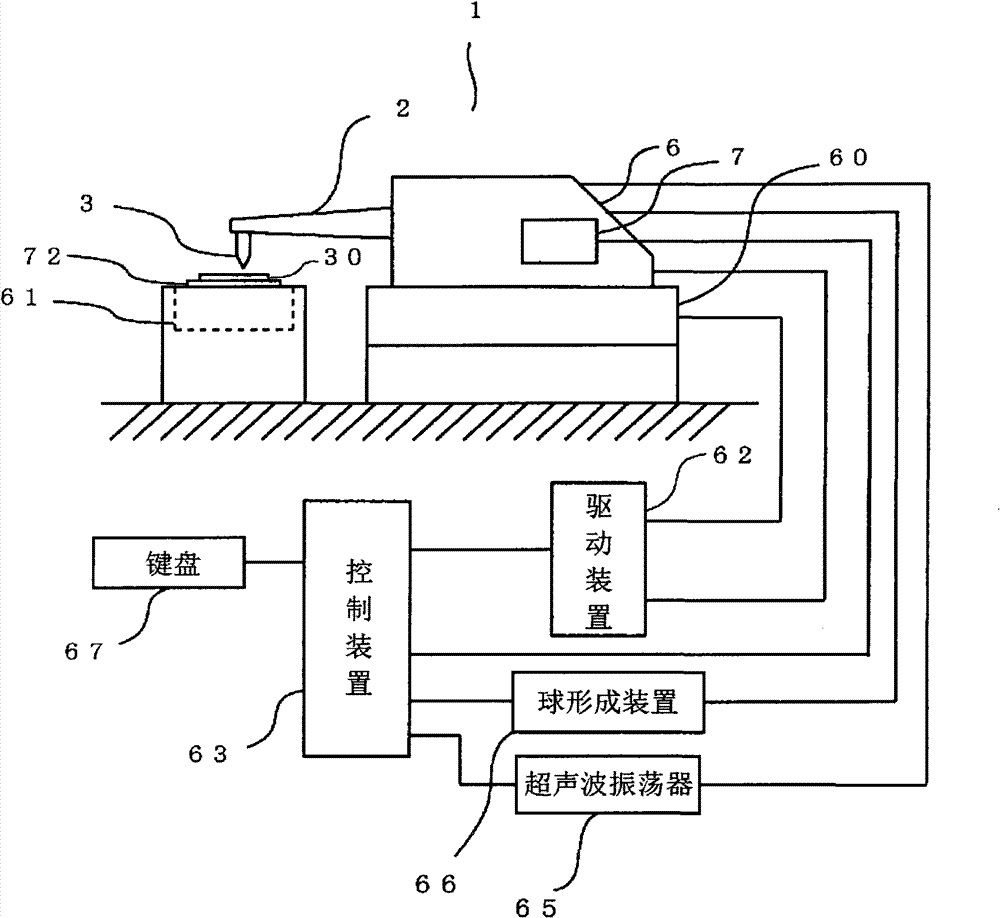

A wire bonding device and wire technology, applied to semiconductor devices, electrical components, circuits, etc., can solve problems such as damage to the lower part of the pad, eccentricity, and reduced quality of wire bonding, and achieve the effect of reducing inflow and gas flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

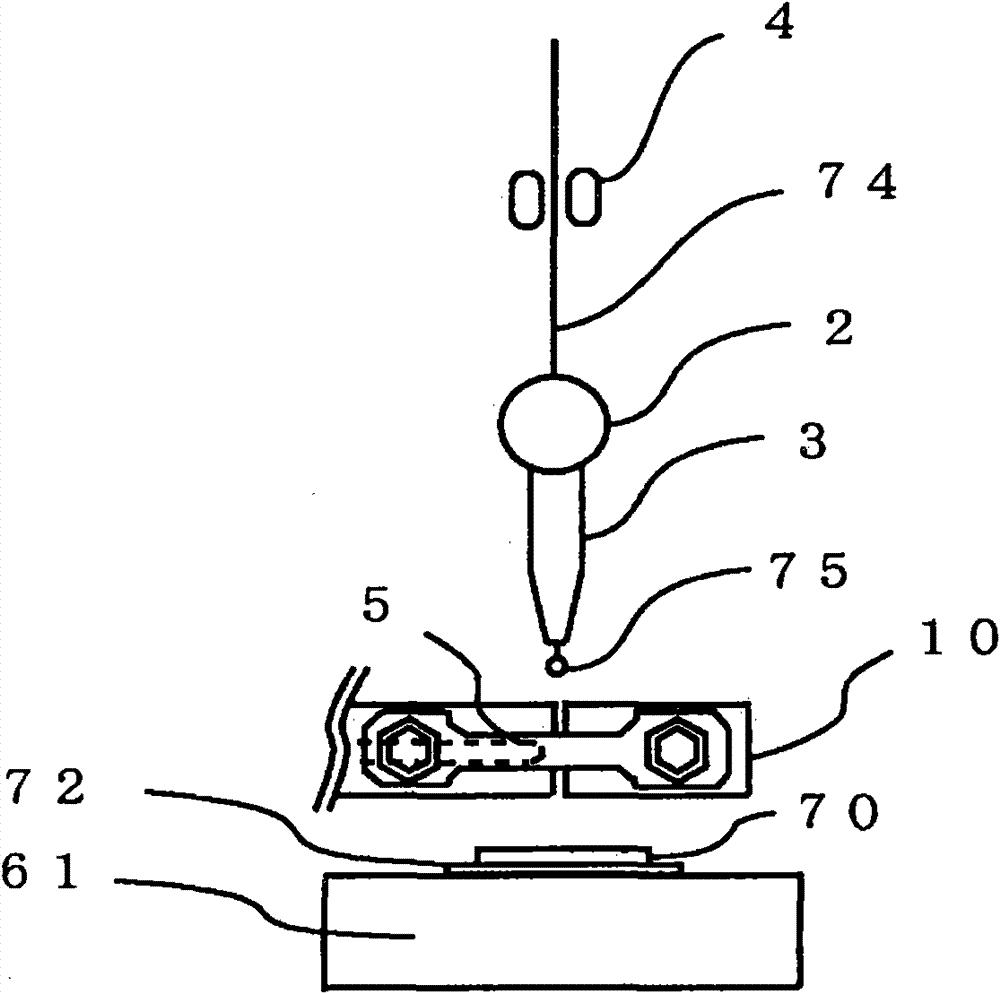

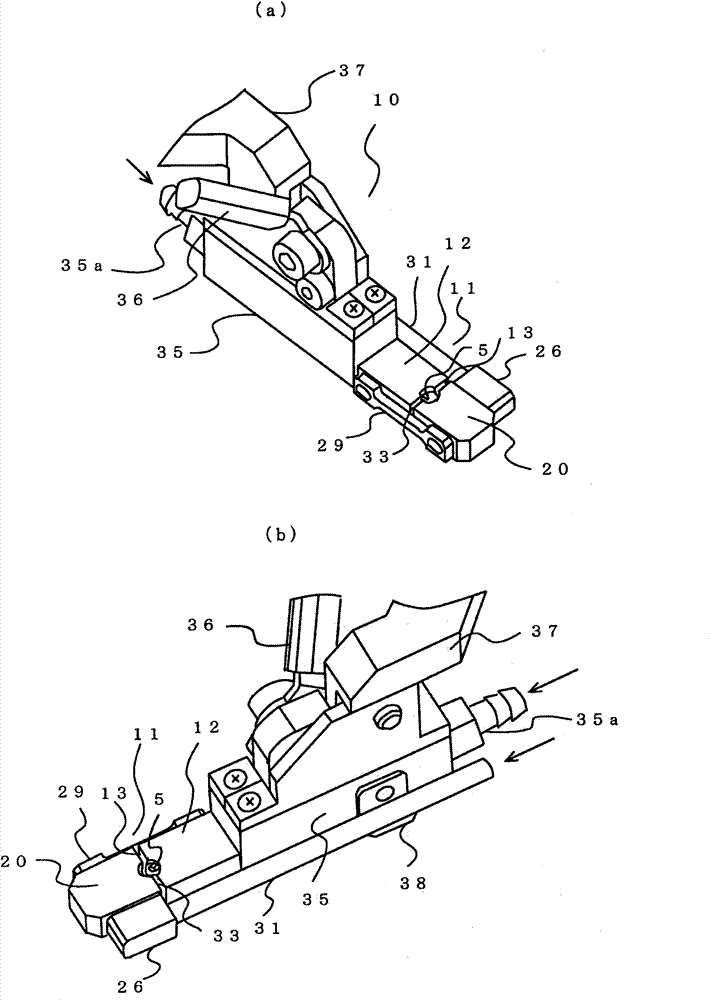

[0150] (gas suction with second exhaust pipe)

[0151] The above-mentioned exhaust pipe flows out the inert gas from the first exhaust pipe 12 and the second exhaust pipe 20 to form an inert gas atmosphere, but as an embodiment, the inert gas can also flow out from the first exhaust pipe 12, and from the opposite The second exhaust pipe 20 sucks gas. Figure 8 It is a figure explaining drawing inert gas by the 2nd exhaust pipe.

[0152] Such as Figure 8 As shown, the inert gas discharged from the first exhaust pipe 12 flows through the space of the inert gas atmosphere, and is exhausted from the second exhaust The gas discharge port 22 of the tube 20 is sucked.

[0153] The inert gas flows out from the first exhaust pipe 12, and the gas is sucked from the opposing second exhaust pipe 20, thereby making the flow of the inert gas constant and forming a stable inert gas atmosphere. In addition, inert gas can be efficiently recovered.

[0154] In addition, since the opening ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com