Nitrogen-reduction fertilizing method capable of improving utilization rate of flue-cured tobacco nitrogenous fertilizer in rainy and smoky area

A technology of fertilization method and utilization rate, applied in the direction of fertilization method, fertilization device, application, etc., can solve the problems of lack of film protection, low accumulation of dry matter and nitrogen, and insignificant effect, and achieve the effect of good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

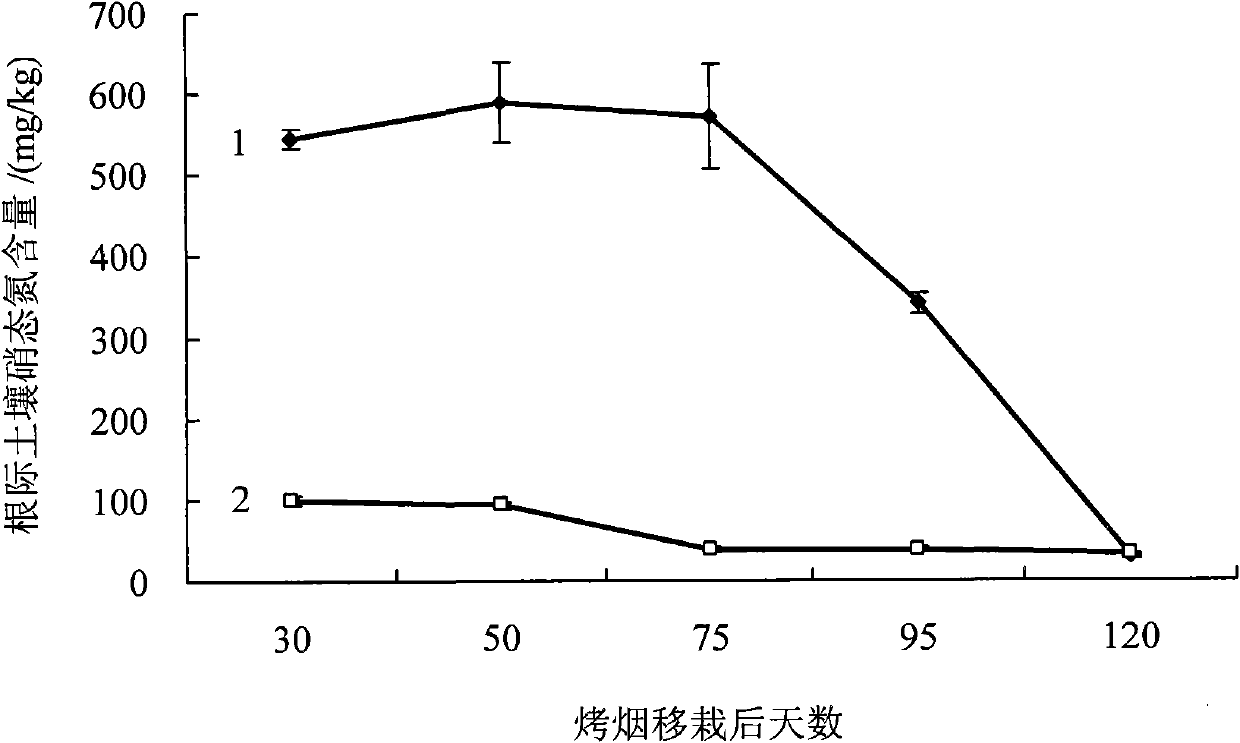

Image

Examples

Embodiment 1

[0017] The purple soil is developed in the Nanxiong Tobacco Area of Guangdong Province, and the long-term implementation of rice-tobacco-water-dry-water-dry-land rotation cropping. The total nitrogen application rate of conventional base fertilizer and topdressing inorganic fertilizer is 7.2kg. Calculated by reducing 55%, the base fertilizer and topdressing fertilizer required after nitrogen reduction The inorganic fertilizer nitrogen total amount is 3.24kg, and potassium nitrate form nitrogen total amount is 2.04kg (63% of inorganic fertilizer nitrogen total amount in base fertilizer and topdressing) in base manure and topdressing, and wherein topdressing potassium nitrate form nitrogen 0.97kg (base manure and topdressing 30% of the total amount of nitrogen in inorganic fertilizers), 1.07kg of nitrogen in the form of potassium nitrate as base fertilizer, and 1.2kg in the form of nitrogen in special compound fertilizer for flue-cured tobacco (37% of the total amount of nitroge...

Embodiment 2

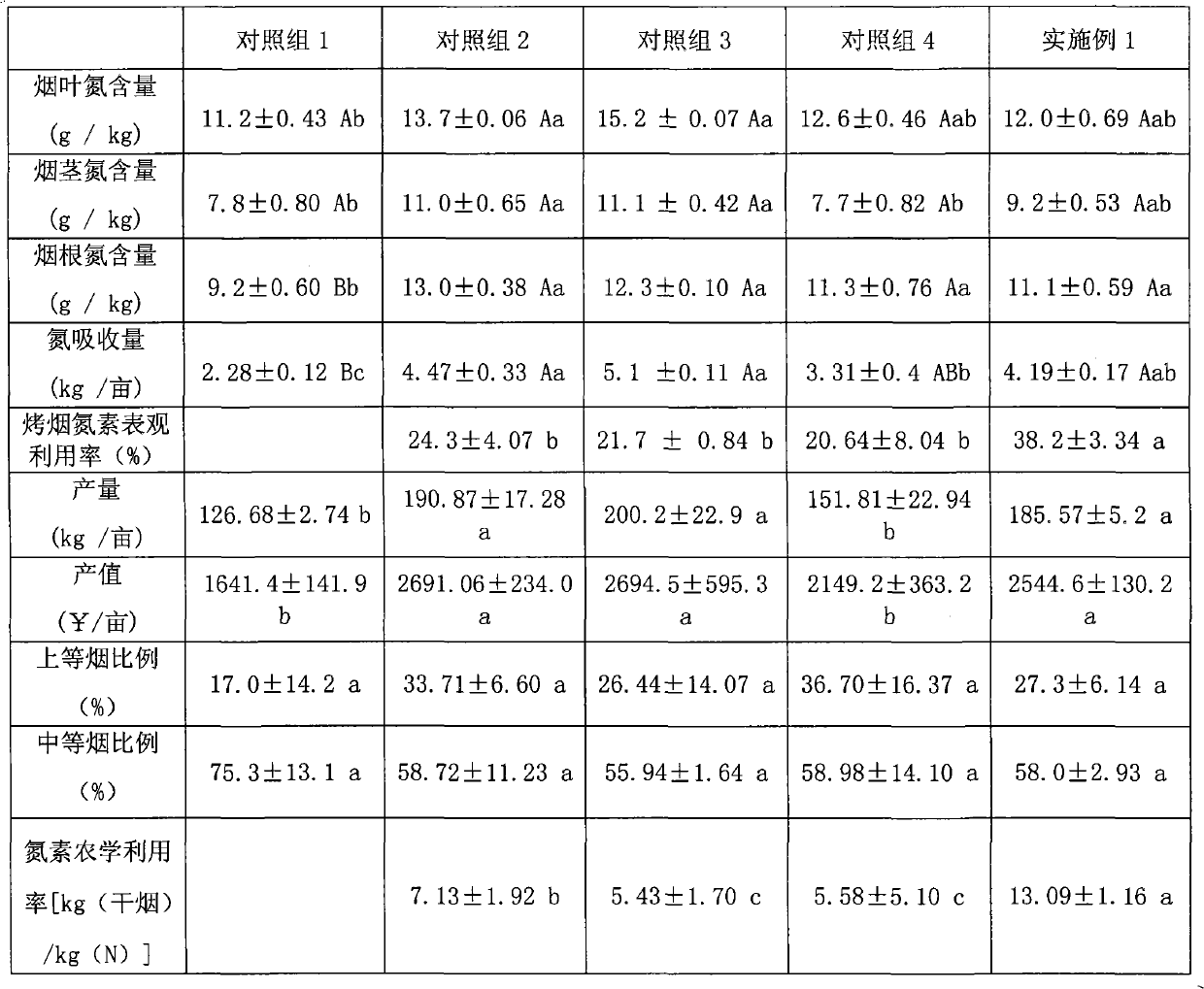

[0021] The flue-cured tobacco obtained in Example 1 was compared with the flue-cured tobacco of the control group with different fertilizer formulations, and the results are shown in Table 1. Values marked with letters of different sizes in the same row indicate significant or extremely significant differences.

[0022] Control group 1: No inorganic fertilizer nitrogen was applied, the total amount of organic fertilizer nitrogen was 4.40kg, of which nitrogen in the form of cake fertilizer was 1.87kg, and nitrogen in the form of pig manure was 2.53kg. Superphosphate 52.59kg was applied as base fertilizer, and decomposed air-dried pig manure (N 0.5%, P 2 o 5 0.2%, K 2 O 0.25%) 506kg, peanut cake fertilizer (N 4.6%, P 2 o 5 1.0%, K 2 O 1.0%) 40.65kg; topdressing potassium sulfate 33.06kg. together with organic fertilizer P 2 o 5 and K 2 O nutrient, N, P per mu 2 o 5 and K 2 O consumption is respectively 4.4kg, 7.73kg and 18.2kg.

[0023] Control group 2: For conv...

Embodiment 3

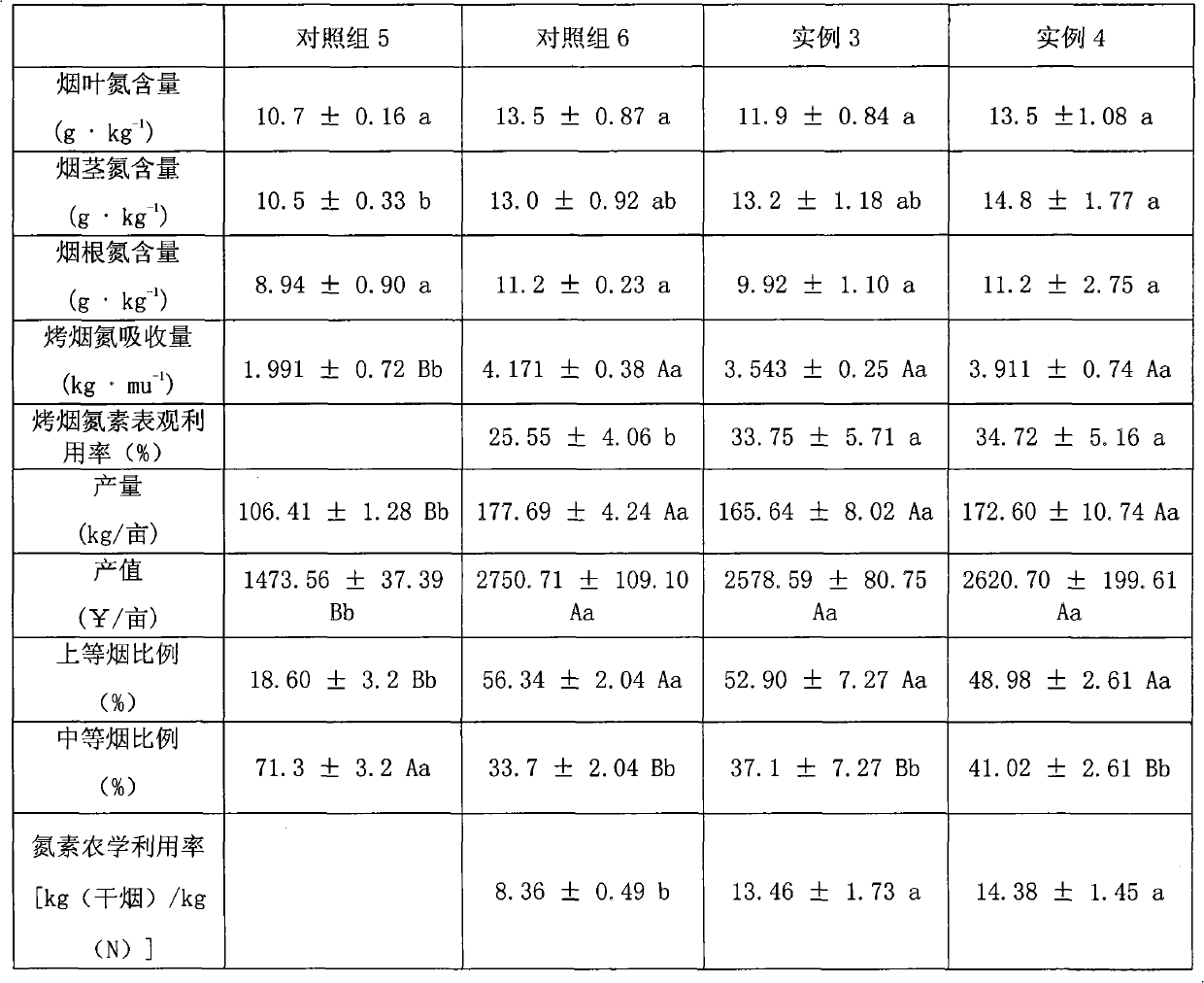

[0033] In 2010, the present invention was implemented in Nanxiong Tobacco Area of Guangdong Flue-cured Tobacco Production Base, further verifying the implementation effect of the technology of the present invention. According to the application rate of 7.2 kg per mu of conventional inorganic fertilizer nitrogen in Nanxiong Tobacco Area, the total amount of inorganic fertilizer nitrogen after nitrogen reduction is 3.96 kg. Among them, the total amount of nitrogen in the form of potassium nitrate in the base fertilizer and topdressing was 2.04kg, accounting for 51.5% of the total nitrogen in inorganic fertilizers; the nitrogen in the form of potassium nitrate in topdressing was 1.188kg, accounting for 30% of the total nitrogen in inorganic fertilizers; the nitrogen in the form of potassium nitrate in base fertilizer was 0.852 kg, 1.92kg of nitrogen in the form of special compound fertilizer for flue-cured tobacco, basal application of inorganic fertilizer nitrogen accounts for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com