Method for slitting, striking and redrying tobacco

A technology for threshing and redrying and tobacco leaves, which is applied in the directions of tobacco, tobacco processing, and application, can solve the problems of reducing the ratio of large and medium flakes, different processing resistance, affecting silk making, etc. The effect of soft and delicate air and uniform leaf structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

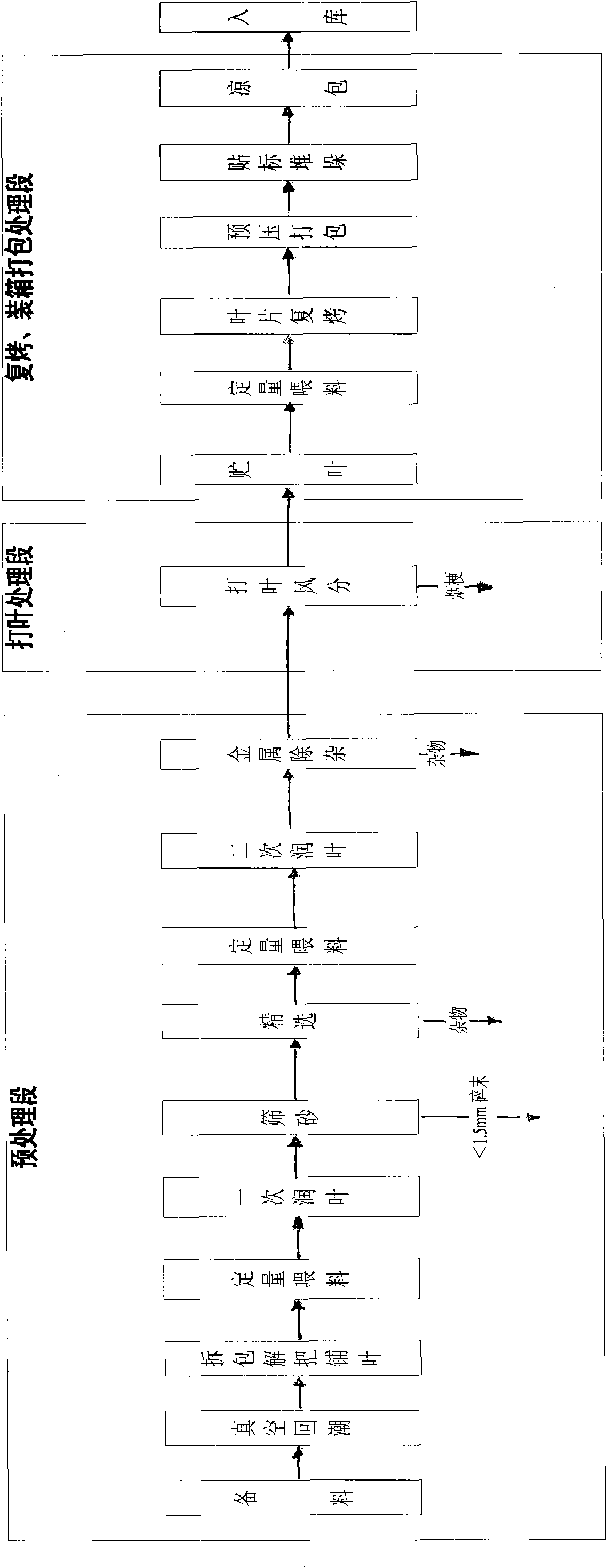

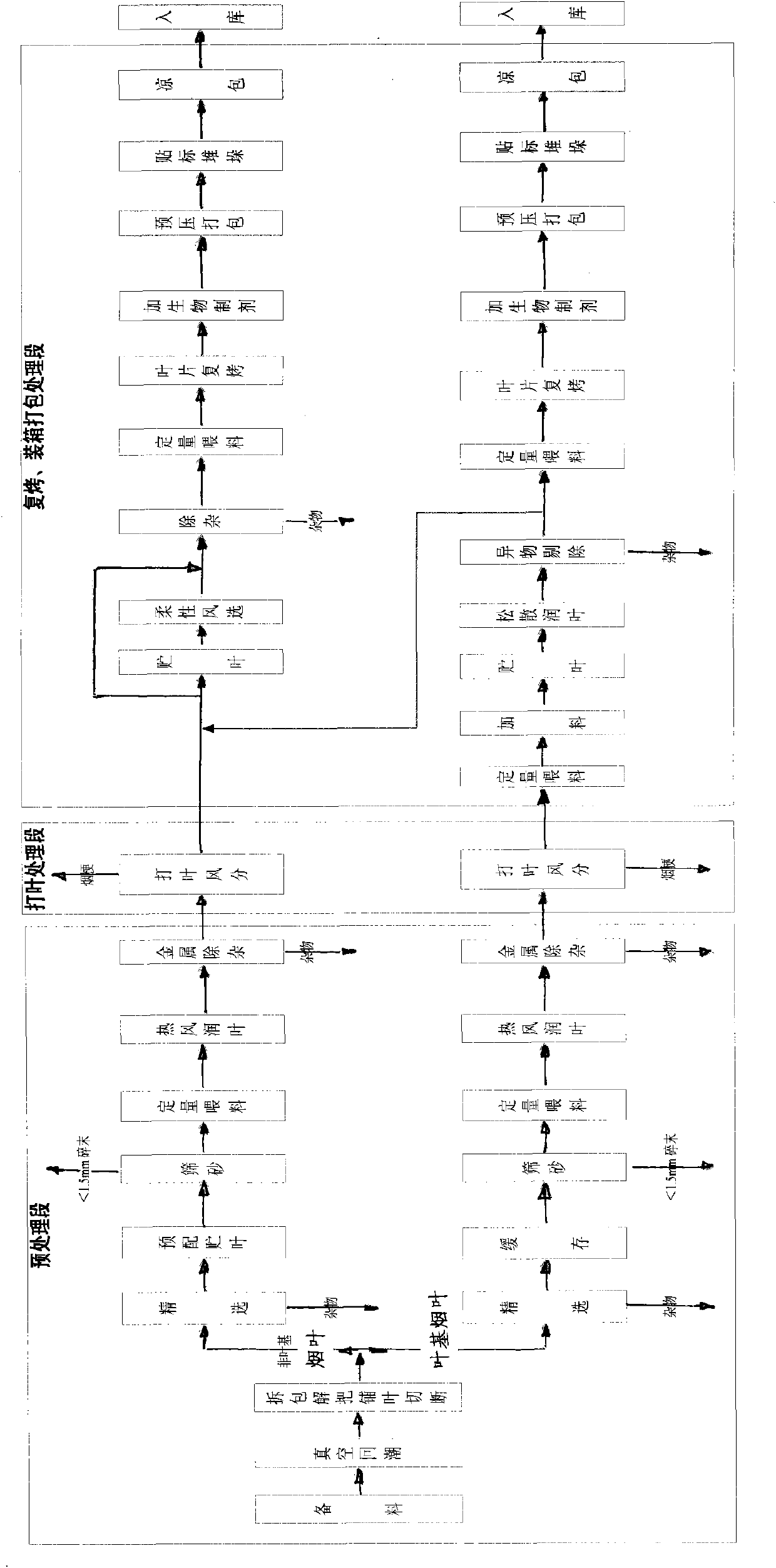

[0059] The production process of the present invention is as follows:

[0060] Tobacco leaves are made into non-leaf-based and leaf-based finished tobacco leaves through the following steps:

[0061] 1. Raw material preparation: According to the production plan, prepare raw materials for processing according to the combination ratio (grade) of the feeding modules.

[0062] 2. Vacuum regain moisture: increase the moisture content and temperature of tobacco raw materials, and improve the processing resistance of tobacco leaves.

[0063] 3. Unpacking, unpacking, laying and cutting: unpacking, unpacking, laying and cutting of tobacco leaf raw materials to realize the separation of leaf base and non-leaf base.

[0064] 4. Selection: manual removal of non-smoking debris and unqualified tobacco leaves.

[0065] 5. Sand sieving: sieve out the sand on the surface of tobacco leaves, reduce dust pollution in subsequent processes and wear on equipment, and sieve out scattered leaves to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com