System for automatically charging a dry powder material

A feeding system and material technology, applied in conveyor objects, transportation and packaging, cleaning devices, etc., can solve the problems of inaccurate addition of pharmaceuticals, large production impact, unevenness, etc., to achieve good economic value and industry promotion value, ensure High-quality, cost-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

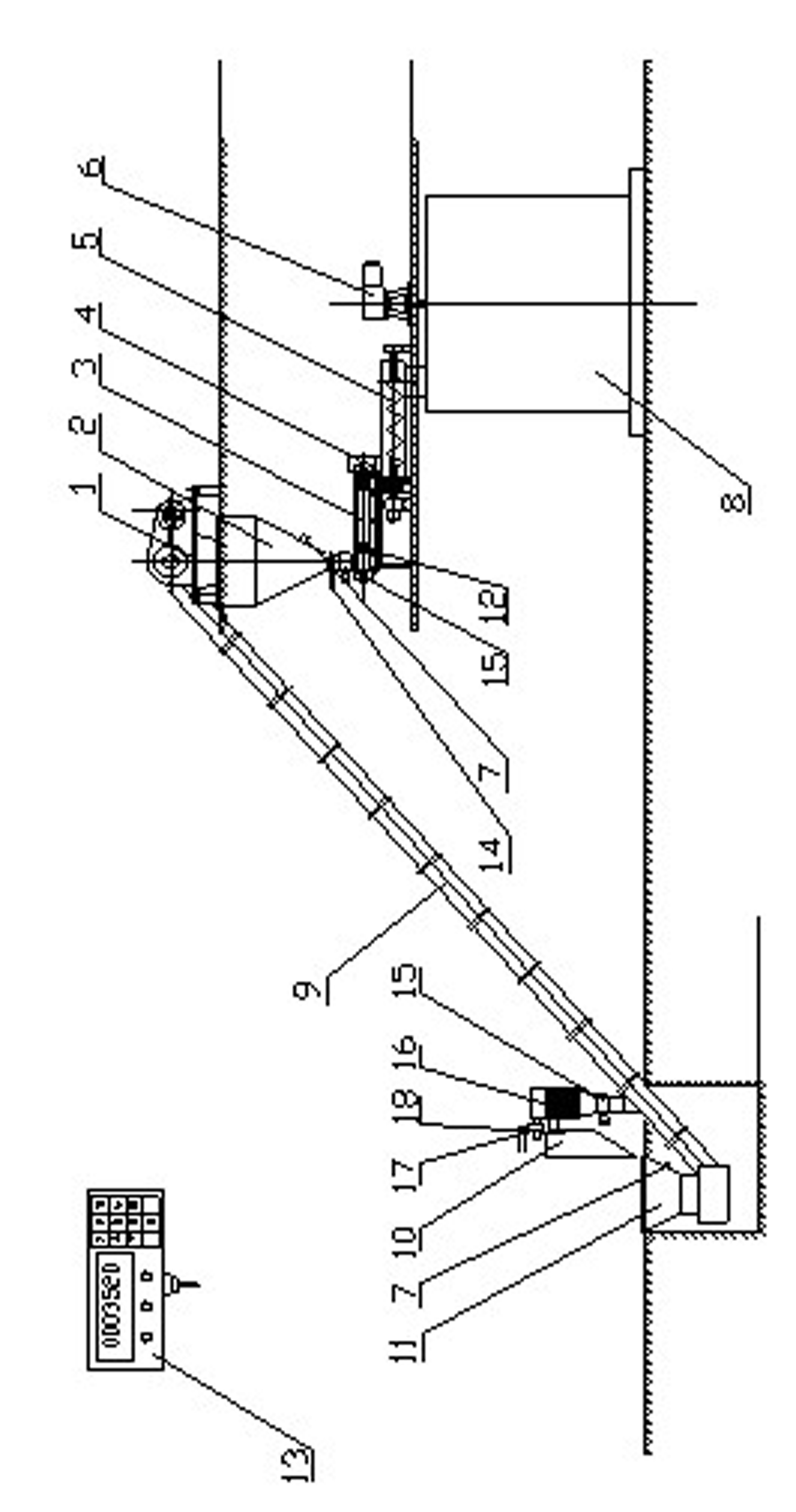

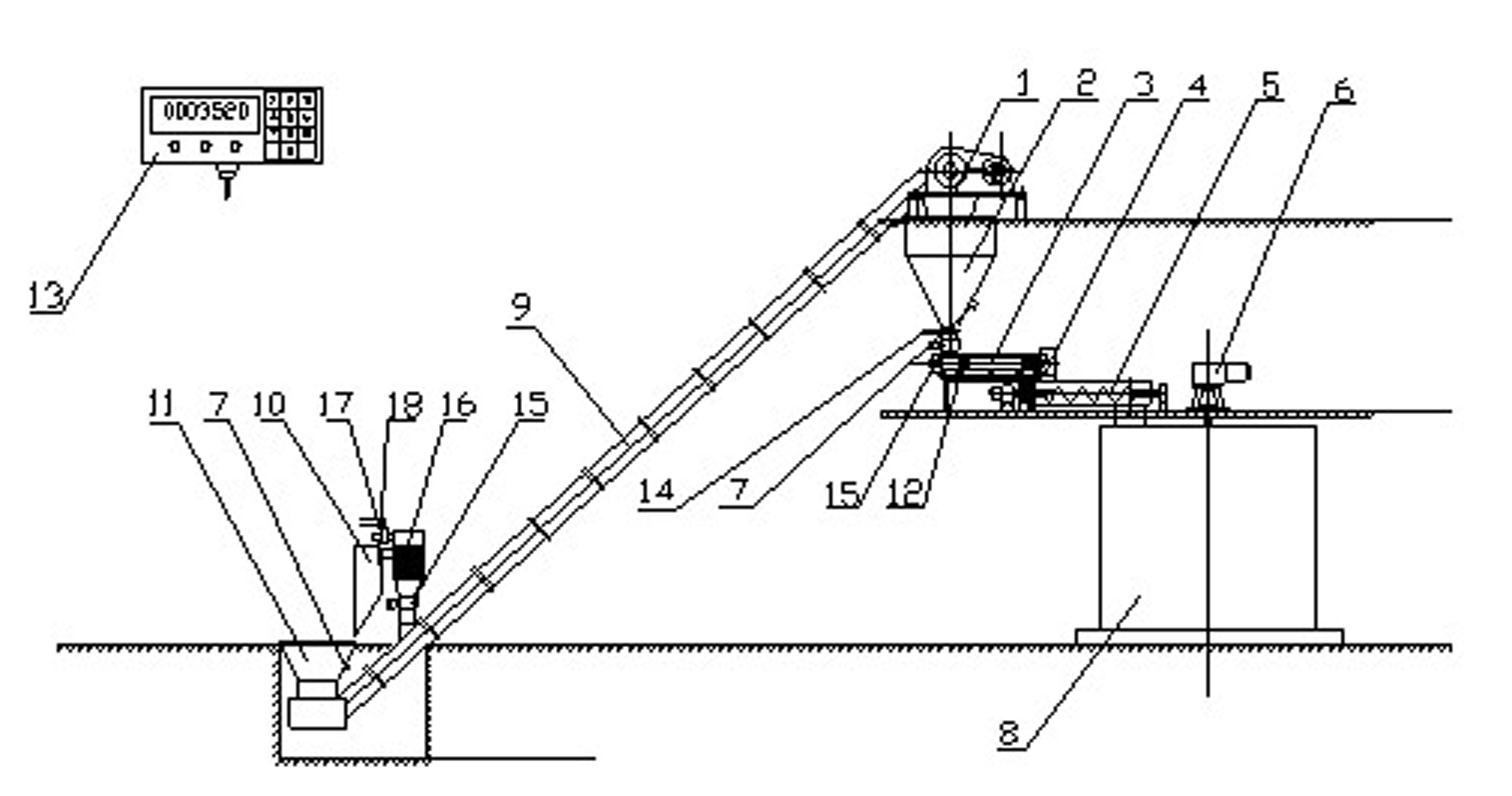

[0029] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0030] The present invention comprises a raw material feeding hopper 11, an electronic belt scale 3, a storage hopper 2, a scraper conveyor 9, a pulping tank 8 and a screw conveyor 5. The feeding hopper 11 is arranged at the lower end of the scraper conveyor 9 , and a storage hopper 2 is arranged at the upper end of the scraper conveyor 9 , and the scraper conveyor 9 is used to transport the raw materials of the feeding hopper 11 to the storage hopper 2 . An electro-hydraulic gate 14 is arranged at the lower end of the storage hopper 2, and the lower end of the electro-hydraulic gate 14 is connected with a star feeder 15, and the star feeder 15 is connected with the storage hopper 2, and the lower end of the star feeder 15 is provided with an electronic belt scale. 3. The star feeder 15 automatically controls the amount of material added to the electronic belt scale...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com