Method for recycling chromic acid in electroplating waste water

A technology of electroplating wastewater and electrochrome plating, which is applied in the direction of chromium trioxide, chromium oxide/hydrate, etc., can solve the problems of not being economical and effective enough, and achieve the effects of saving material consumption, good practicability, and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The content of the present invention will be further described below in conjunction with the accompanying drawings and embodiments. The present invention is not limited to this embodiment, and any technical solution formed by equivalent replacement or equivalent replacement falls within the protection scope of the present invention.

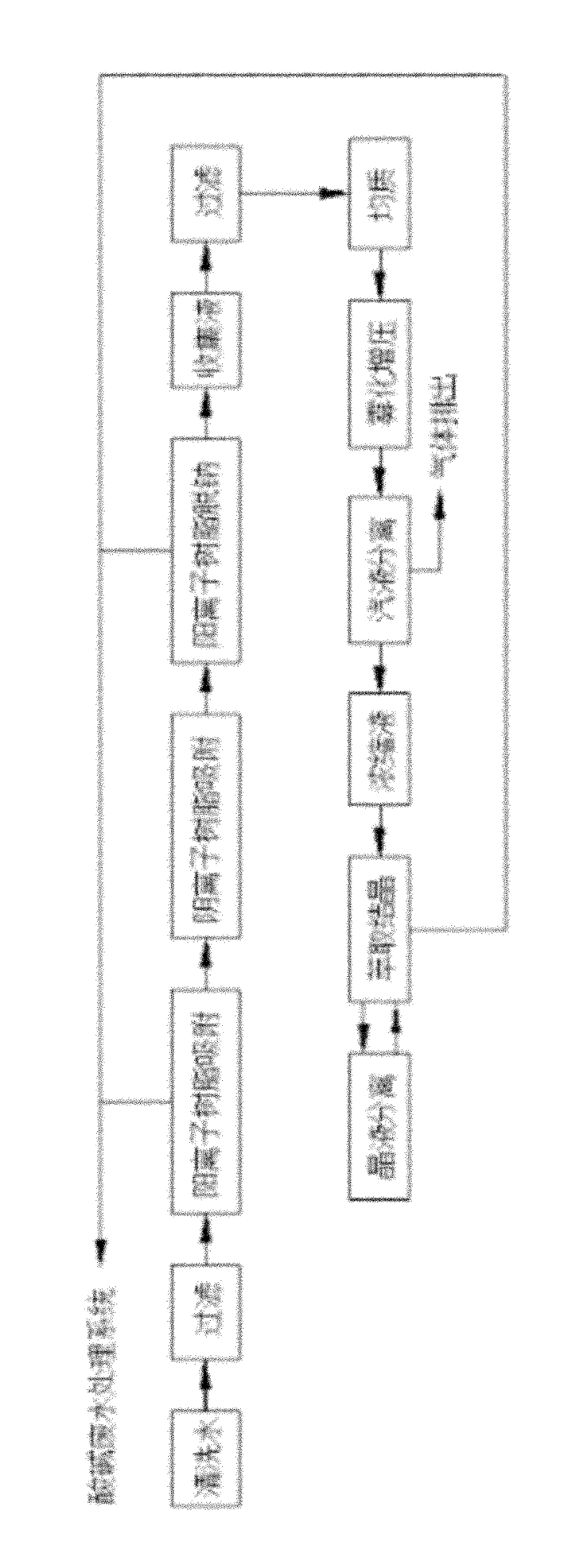

[0035] The following takes the recovery of chromic acid in a kind of electroplating cleaning wastewater as an example for specific instructions, and its overall process is as follows: figure 1 shown.

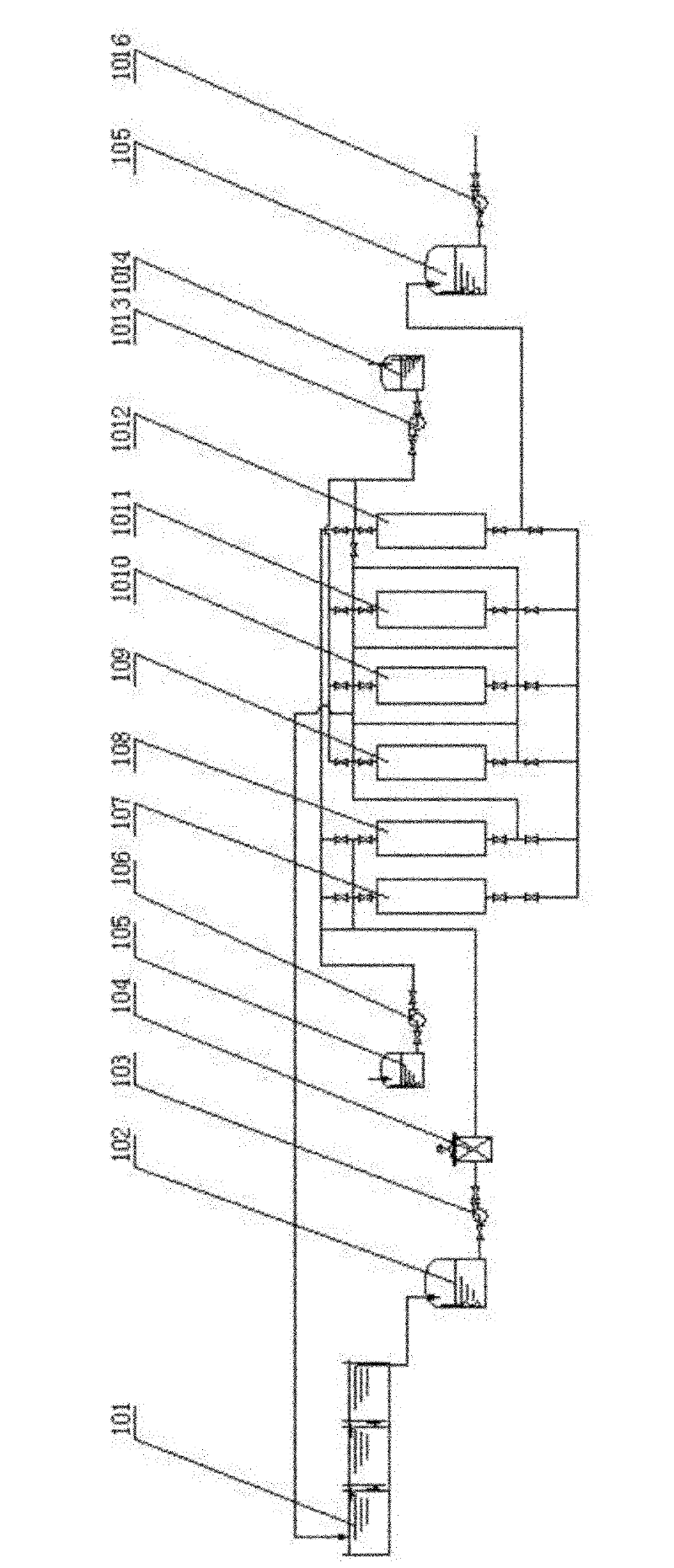

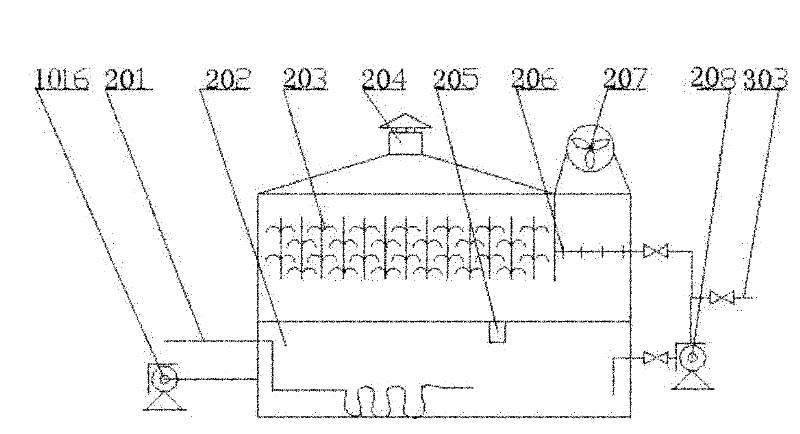

[0036] A. Chromic acid collection: see process flow figure 2 , the main component characteristics of the water quality before the treatment of the present embodiment: nickel ion2 o 7 -2 into CrO 4 -2 , then OH - Replacing CrO on Resin 4 -2 , the chromium in the regeneration solution obtained by leaching is Na 2 CrO 4 , must undergo ion exchange into H 2 Cr 2 o 7 to be recycled. Desodium column (1012) adopts H + type of cation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com