Preparation method of brake molybdenum disulfide-Cu-Fe radical friction material

A technology of molybdenum disulfide and friction materials, which is applied in the direction of friction linings, mechanical equipment, etc., to achieve the effects of controllable sintering temperature, cost saving and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

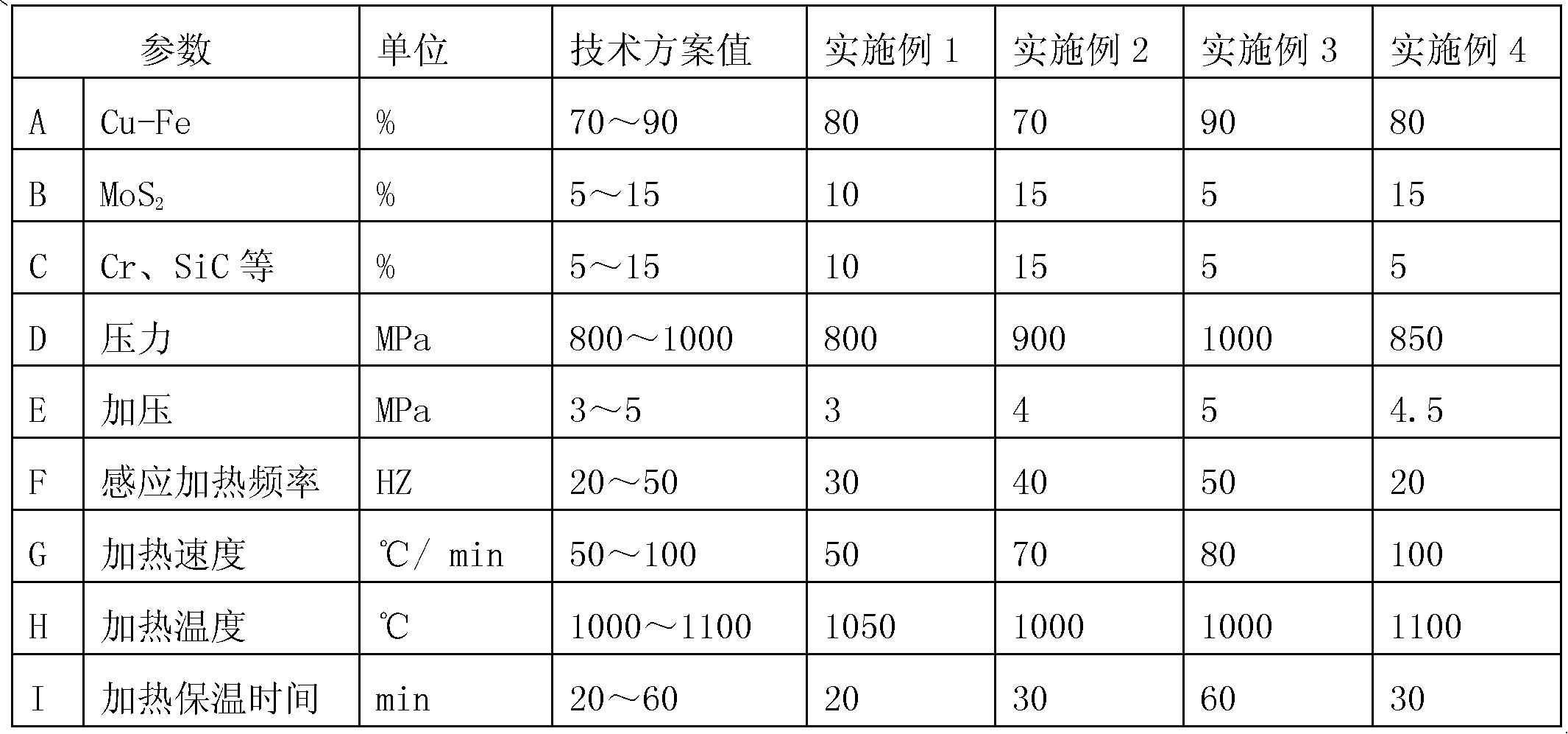

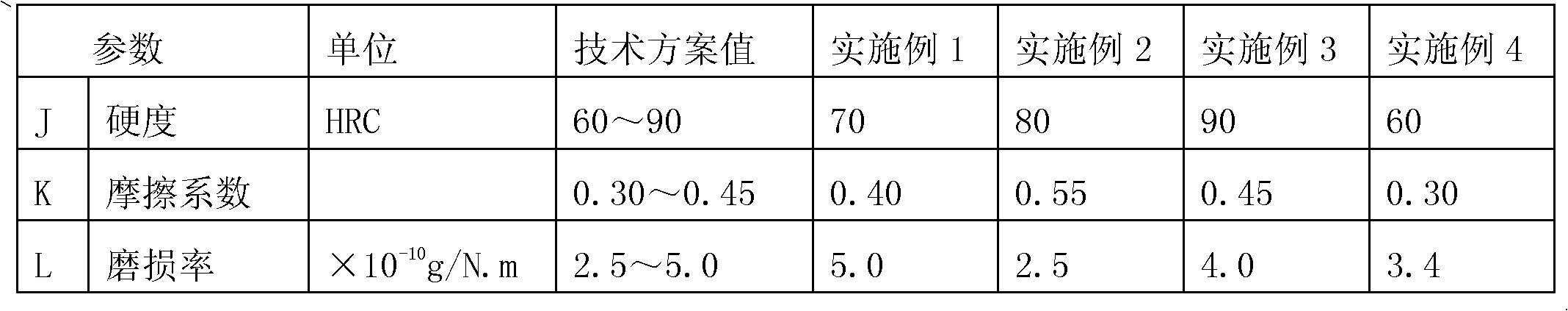

Embodiment 1

[0027] (1) Manufacturing process:

[0028] Electrolytic copper powder: particle size less than 75μm, Cu purity greater than 99.9%;

[0029] Reduced iron powder: particle size less than 75μm, Fe purity greater than 99.9%;

[0030] Molybdenum disulfide powder: particle size less than 75μm; C purity greater than 99.9%;

[0031] Silica powder: particle size less than 75μm, SiO 2 The purity is greater than 99.9%, etc.

[0032] Manufacturing process:

[0033] According to a certain mass ratio (Cu-Fe: 80%; MoS 2 : 10%; Cr, Mn and SiC, etc.: 10%) Weigh the corresponding powder, and then mechanically mix it evenly;

[0034] Under the pressure of 800MPa, use powder metallurgy compression molding method to press into a 20mm cylindrical compact; put the compact into a stainless steel container with a wall thickness of 2mm, and fill it with protective gas;

[0035] Put the container in the coil of the medium-frequency induction heating power supply, heat and burn for sintering under ...

Embodiment 2

[0040] (1) Manufacturing process:

[0041] Electrolytic copper powder: particle size less than 75μm, Cu purity greater than 99.9%;

[0042] Reduced iron powder: particle size less than 75μm, Fe purity greater than 99.9%;

[0043] Molybdenum disulfide powder: particle size less than 75μm; C purity greater than 99.9%;

[0044] Silica powder: particle size less than 75μm, SiO 2 The purity is greater than 99.9%, etc.

[0045] Manufacturing process:

[0046] According to a certain mass ratio (Cu-Fe: 70%; molybdenum disulfide, MoS 2 : 15%; Cr, Mn and SiC, etc.: 15%) Weigh the corresponding powder, and then mechanically mix it evenly;

[0047] Under the pressure of 900MPa, use the powder metallurgy compression molding method to press into a 20mm cylindrical compact; put the compact into a stainless steel container with a wall thickness of 2mm, and fill it with protective gas;

[0048] Put the container in the coil of the medium-frequency induction heating power supply, heat and...

Embodiment 3

[0053] (1) Manufacturing process:

[0054] Electrolytic copper powder: particle size less than 75μm, Cu purity greater than 99.9%;

[0055] Reduced iron powder: particle size less than 75μm, Fe purity greater than 99.9%;

[0056] Molybdenum disulfide powder: particle size less than 75μm; C purity greater than 99.9%;

[0057] Silica powder: particle size less than 75μm, SiO 2 The purity is greater than 99.9%, etc.

[0058] Manufacturing process:

[0059] According to a certain mass ratio (Cu-Fe: 90%; molybdenum disulfide, MoS 2: 5%; Cr, Mn and SiC, etc.: 5%) Weigh the corresponding powder, and then mechanically mix it evenly;

[0060] Under the pressure of 1000MPa, use the powder metallurgy compression molding method to press into a 20mm cylindrical compact; put the compact into a stainless steel container with a wall thickness of 2mm, and fill it with protective gas;

[0061] Put the container into the coil of the medium-frequency induction heating power supply, heat and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

| Wear rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com