Flue gas sampling device

A flue gas sampling and gas sampling technology, applied in the fields of detection and analysis, and gas sampling, can solve the problems of long-term work, difficult sampling pump, overload damage of sampling pipeline sampling pump, etc., and achieve the effect of long-term reliable work.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

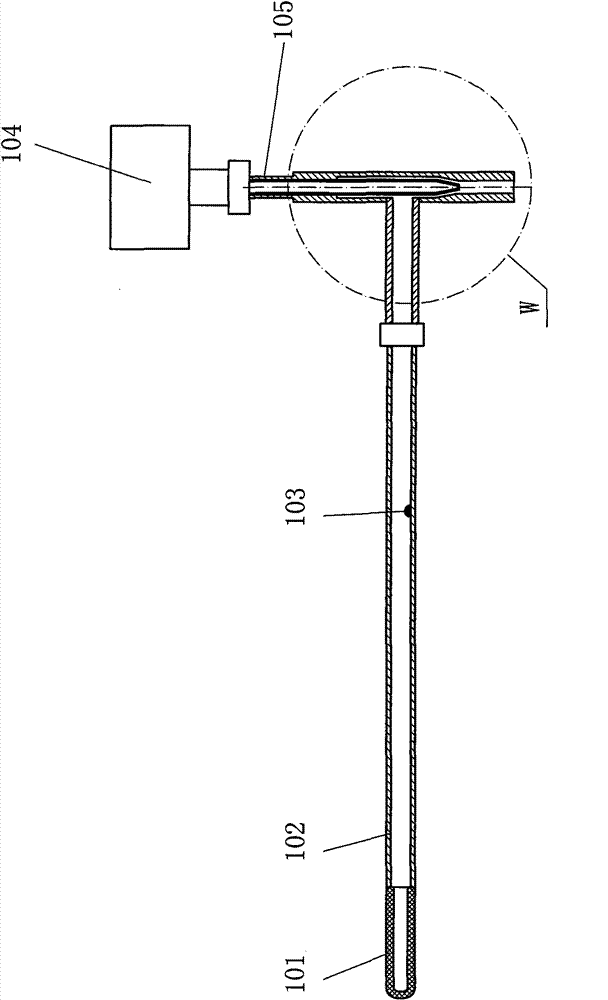

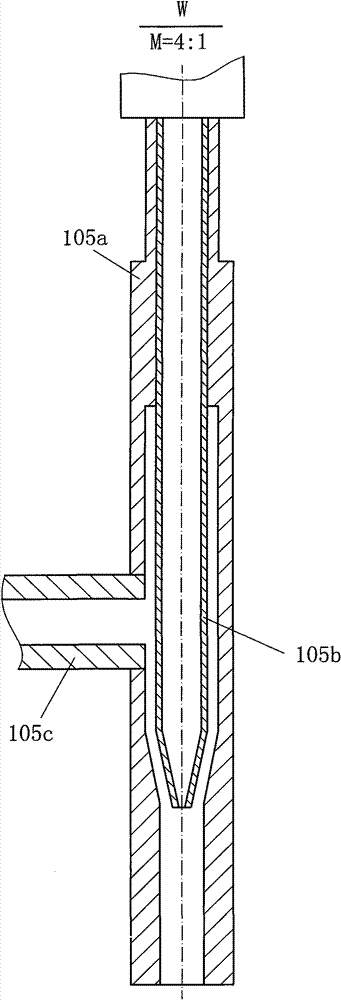

[0065] combine figure 1 and figure 2 Be explained.

[0066] figure 1 is one of the schematic diagrams of the device of the present invention; figure 2 yes figure 1 The partial enlarged picture at W in the center, the magnification ratio is 4:1, this picture expresses the structure diagram of the jet injector for cross-section processing. Explanation of symbols in the figure: 101. filter; 102. hollow rod; 103. probe; 104. air source machine; 105. jet injector; 105a. injector main body;

[0067] Such as figure 1 As shown, the left front end of the hollow rod 102 is provided with a filter 101; the filter 101 is located in the most typical and representative smoke environment. The right end of the hollow rod 102 communicates with the injector body 105a through a transverse cylinder 105c.

[0068] When the air source machine 104 provides high-speed gas to the jet injector 105, the gas enters the upper part of the nozzle 105b (the first inlet end of the jet injector 105), a...

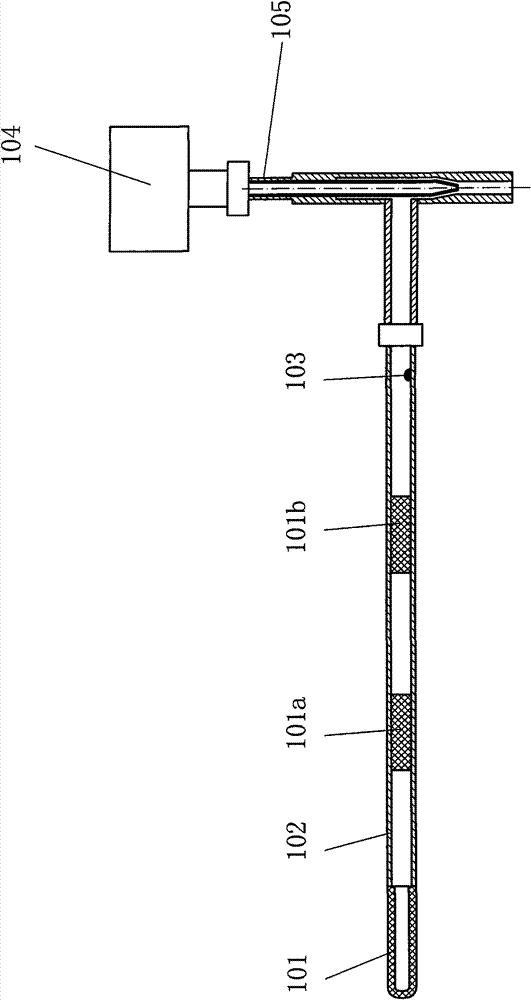

Embodiment 2

[0071] combine image 3 Be explained. image 3 Explanation of symbols in: 101. filter; 101a. second filter; 101b. third filter; 102. hollow rod; 103. probe; 104. air source machine; 105. jet injector.

[0072] In this example image 3 and in Example 1 figure 1 In comparison, the difference is that: figure 1 A single filter is used for filtering; and image 3 The three filters that play a role in filtering are the first filter 101, the second filter 101a, and the third filter 101b; the sample gas flows from the first filter 101, the second filter 101a, and the third filter in sequence 101b filtered through.

[0073] The third filter 101c, the probe 103, and the jet injector 105 are also arranged sequentially in the gas path through which the sample gas flows.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com