Photovoltaic assembly and preparation method thereof

A technology of photovoltaic components and components, which is applied in the field of solar energy, can solve the problems of rising temperature of photovoltaic components, shortening life of photovoltaic components, and reducing service life, and achieves the effects of lower operating temperature, simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

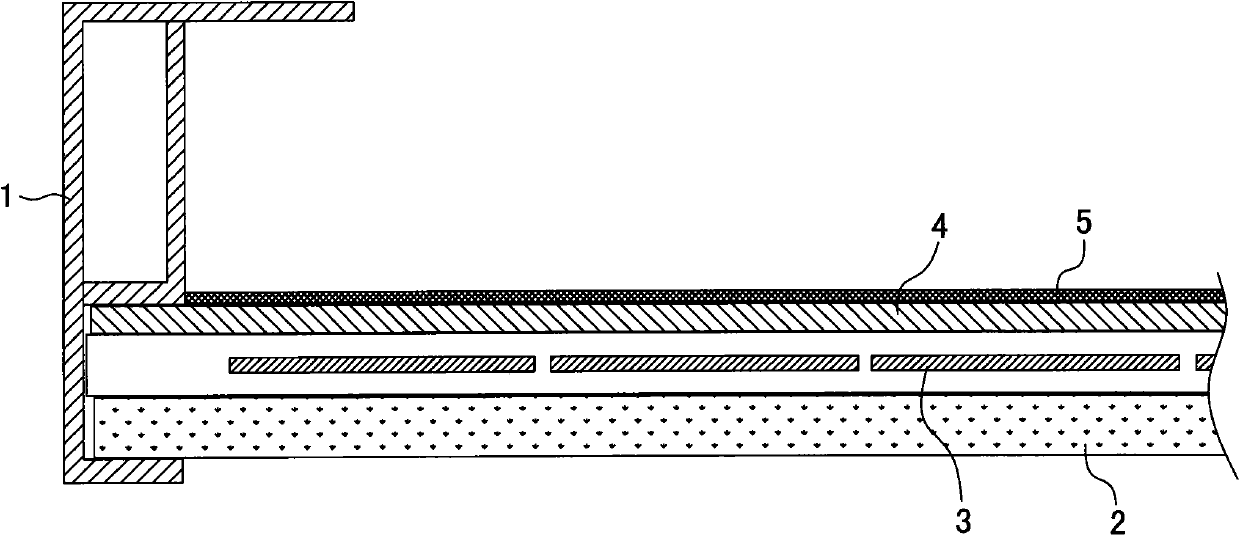

[0023] see figure 1 As shown, a photovoltaic module includes a frame 1 and a glass top plate 2 arranged in the frame, a cell sheet 3 and a back plate 4. The back plate 4 is provided with a high infrared emissivity layer 5, and the high infrared emissivity Layers can be produced by coating.

[0024] The high infrared emissivity layer is a high infrared emissivity coating or a high infrared emissivity film layer. The coating or film layer is made from the following raw materials: Mn 2 o 3 , NiO, Gr 2 o 3 , Fe 2 o 3 , CoO, CuO, Al 2 o 3 .

[0025] Tests show that the emissivity of the high infrared emissivity layer is about 80% at 25°C and close to 90% at 50°C.

Embodiment 2

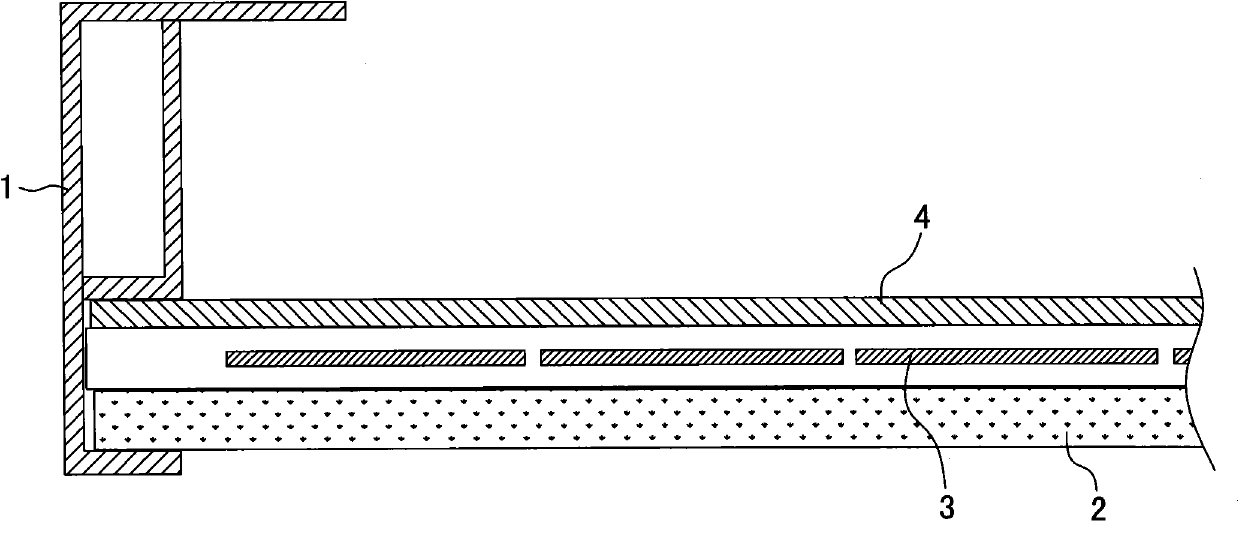

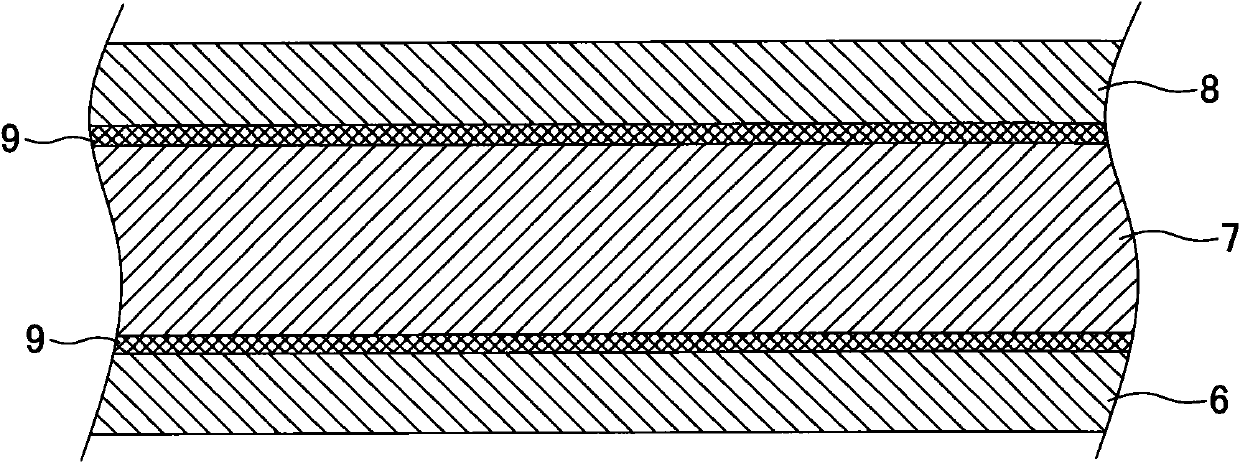

[0030] see Figure 2~3 As shown, a photovoltaic module includes a frame 1 and a glass top plate 2, a battery sheet 3 and a back plate 4 arranged in the frame,

[0031] The backboard includes an outer PVF layer, a polyester film layer, and an inner PVF layer, and the outer PVF layer contains infrared radiation materials to form the high infrared radiation rate structure.

[0032] The working principle of the present invention is: the backplane is made into a high-infrared emissivity backplane, and its area and position should cover the area of the front solar cell group, thereby increasing the heat transfer of the module to the surrounding environment through radiation, reducing the operating temperature of the module, and then Reduce the output loss of components due to temperature rise, and at the same time prolong the service life of components; Radiative materials are fabricated with maximum emissivity over the component operating temperature range.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com