Rotary distribution and membrane flash evaporation specific gravity differential concentrator

A technology of concentrator and poor specific gravity, applied in the field of concentrators, can solve the problems of easy destruction of heat-resistant components of material liquid, high steam energy consumption of concentrators, high power consumption and product quality, etc., so as to avoid friction and power consumption. Small, good quality results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

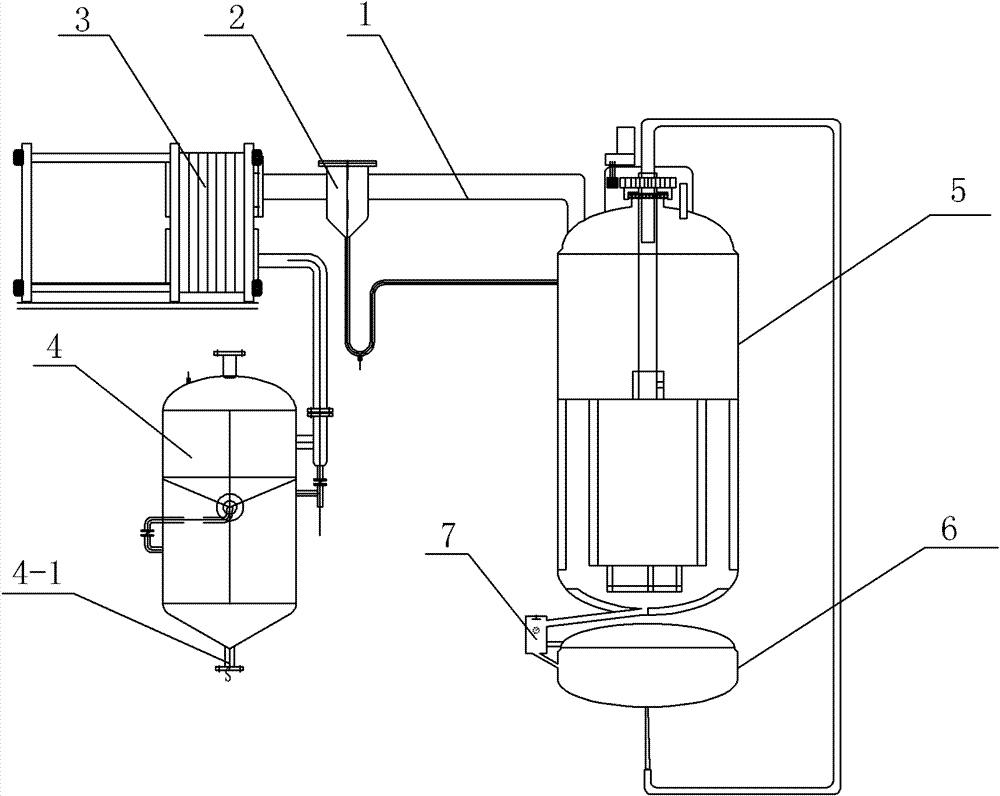

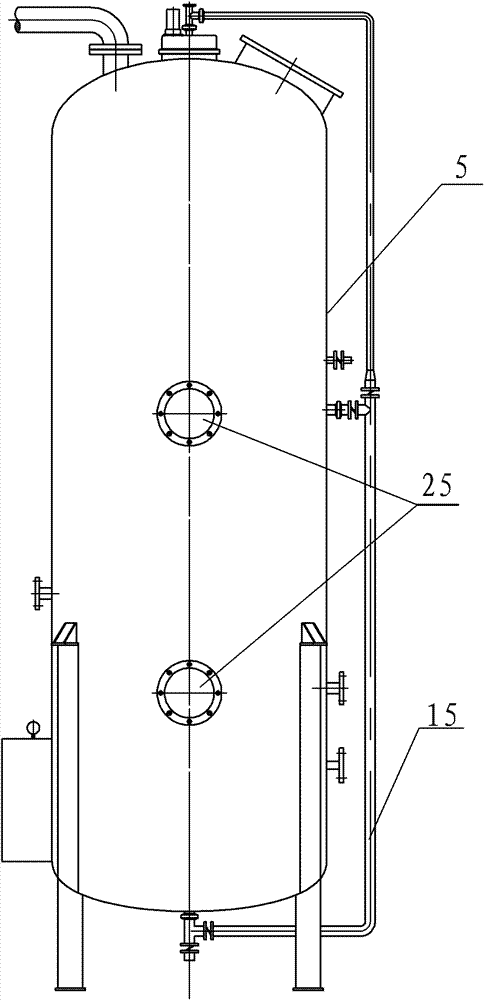

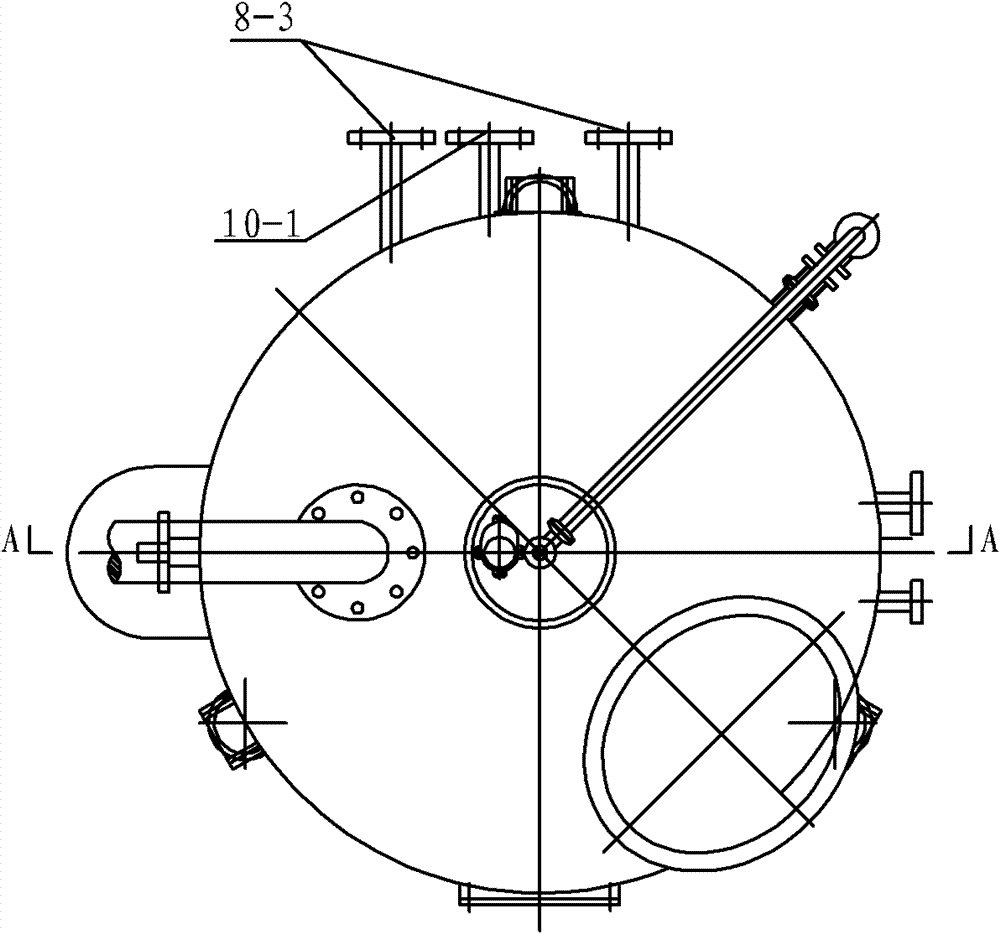

[0009] Specific implementation mode one: combine Figure 1-Figure 8 Description of this embodiment, the concentrator of this embodiment includes an evaporation tube 1, a vapor-liquid separator 2, a condenser 3 and a recovery liquid collector 4, and the bottom of the recovery liquid collector 4 is provided with a recovery liquid discharge port 4-1 , one end of the vapor collection pipe 1 communicates with the inlet of the vapor-liquid separator 2, the outlet of the vapor-liquid separator 2 communicates with the inlet of the condenser 3, and the outlet of the condenser 3 communicates with the inlet of the recovery liquid collector 4 The concentrator also includes a material distribution device, an evaporation tank 5, a collection tank 6, a density measuring device 7, an intermediate jacket 8, an outer jacket 9, a bottom jacket 10, a condensate drain pipe 11, a discharge pipe 13, The total feed pipe 14, the first sub-feed pipe 15 and two steam inlet pipes 12;

[0010] Described ...

specific Embodiment approach 2

[0013] Specific implementation mode two: combination Figure 4 To illustrate this embodiment, the top of the evaporation tank 5 of this embodiment is provided with a quick-opening inlet 5-2, and this structure is used for fast feeding of feed liquid. Other components and connections are the same as those in the first embodiment.

specific Embodiment approach 3

[0014] Specific implementation mode three: combination Figure 4-Figure 6 To illustrate this embodiment, the outer jacket 9 of this embodiment is provided with a first condensed gas outlet 9-2, and the bottom jacket 10 is provided with a third condensed gas outlet 10-2, and this structure is used for exhausting. Other components and connections are the same as those in the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com