Design scheme of standardized electric flocculation equipment

A design scheme and electrocoagulation technology, applied in chemical instruments and methods, flotation water/sewage treatment, water/sewage treatment, etc., can solve the problems of immature equipment design scheme and difficult standardization of equipment, and improve water flow turbulence Degree, rationalization of equipment structure, and the effect of preventing electrode passivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] Now in conjunction with accompanying drawing, structure and principle of the present utility model are described further.

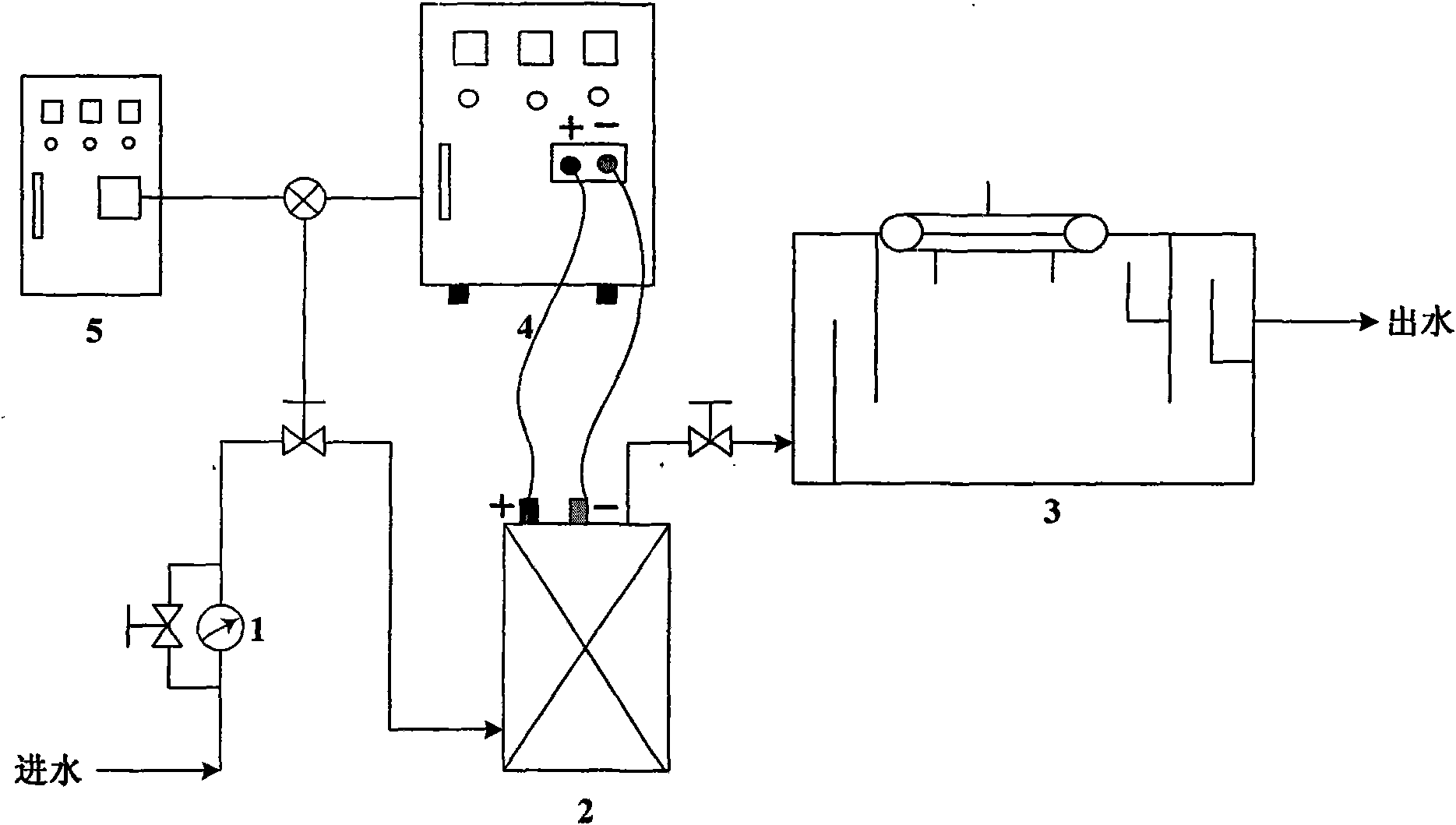

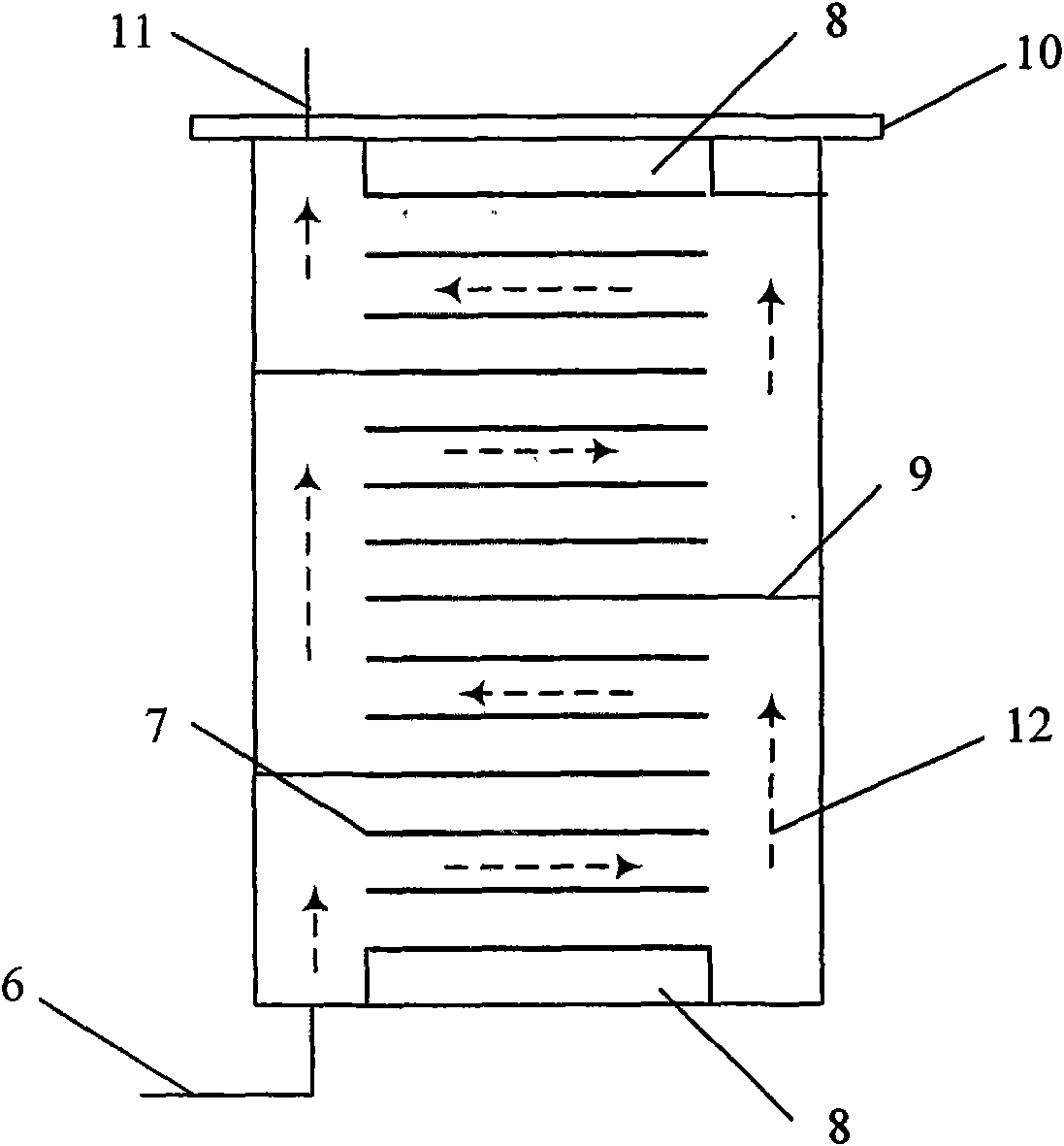

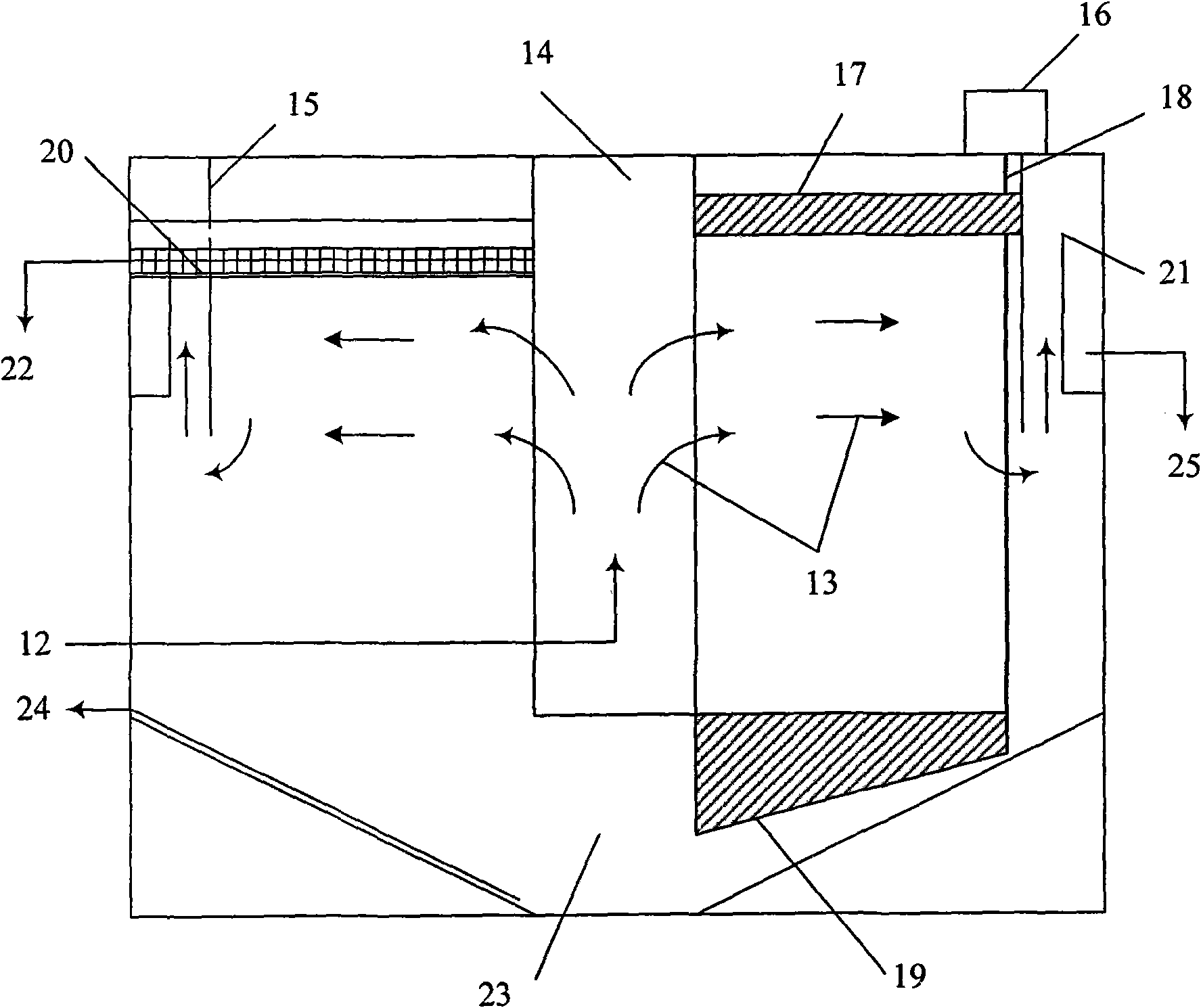

[0052] figure 1 It is the composition diagram of the standardized electrocoagulation equipment. It can be seen from the figure that the standardized electrocoagulation equipment is usually composed of a flow regulating device (1), an electrolytic reactor (2), a separation device (3), a power supply (4) and a control system (5). Among them, the flow regulating device is used to measure and adjust the flow of wastewater entering the electrocoagulation device; the electrolytic reactor is composed of a group of metal electrode plates, which electrolyze and generate metal hydroxide flocs and hydrogen gas under the condition of electrification, thereby producing flocculation and air flotation The separation device provides a place for the separation of pollutants in wastewater through flocculation and air flotation. Its essence is an air flotation sedim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com