Fluidized-bed pyrolysis device for preparing biomass gas with high calorific value

A technology of biomass gas and fluidized bed, which is applied in the direction of gasification device feeding tools, manufacture of combustible gas, granular/powdered fuel gasification, etc. It can solve the problems of no practical case, high operating cost, and poor economy. Achieve the effects of avoiding the separation process of nitrogen and gas, improving heat and mass transfer efficiency, and realizing multi-level utilization of energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

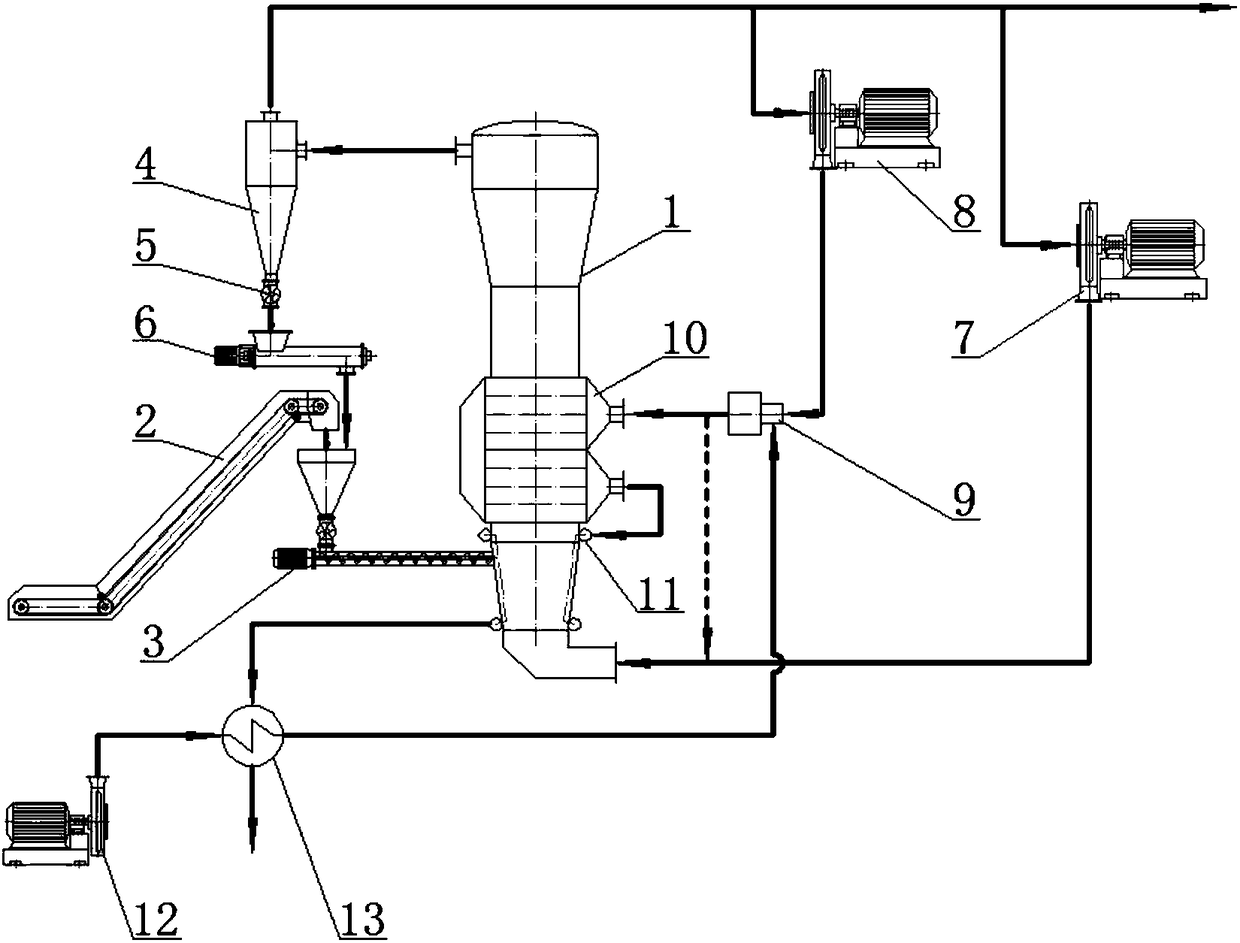

[0026] Please refer to figure 1 , a fluidized bed pyrolysis device for preparing high calorific value biomass gas, comprising a fluidized bed 1, a cyclone separator 4, a heat exchanger 10 and a feeder 3, and the feeder 3 is used for crushing and drying biomass The material material is sent to the fluidized bed 1, the inlet of the cyclone separator 4 is connected with the top of the fluidized bed 1, and the heat exchanger 10 is arranged in the dense phase section in the fluidized bed, and the heat exchanger 10 is The biomass material provides the heat required for pyrolysis, and also includes a booster fan 8 and a biomass gas burner 9. The exhaust port of the cyclone separator 4 is connected with the inlet of the booster fan 8, and the outlet of the booster fan 8 The gas port is connected with the air inlet of the burner 9 , and the hot flue gas outlet of the burner 9 is connected with the heat medium inlet of the heat exchanger 100 . Wherein, the heat exchanger 10 is a silico...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com