Foam coke-quenching method

A technology of foam and additives, applied in the field of coke quenching technology, can solve the problems of harmful steam being discharged to the atmosphere, high equipment cost, and reduced coke quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

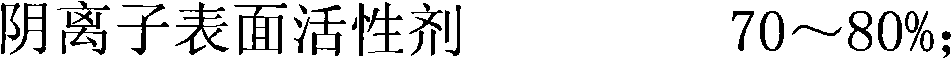

[0013] First prepare the foam quenching additive, and its weight percent composition is as follows:

[0014]

[0015] Dissolve the prepared foam coke quenching additive in water at a ratio of 1:9 to prepare an aqueous solution with a concentration of 10% by weight, and then pour this high-concentration aqueous solution and water at a ratio of 1:200 for coke quenching Pool, prepare a dilute aqueous solution with a concentration of 0.05% by weight, then pump the dilute aqueous solution into the sprayer, and spray it on the high-temperature red coke. When the temperature of the coke drops below 200°C, stop the spraying and withdraw the coke .

Embodiment 2

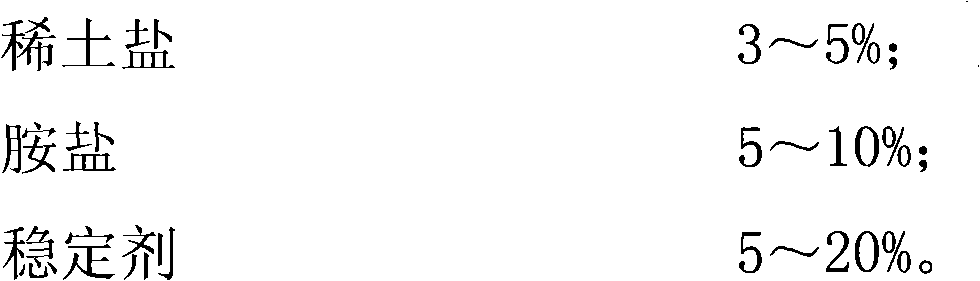

[0017] First prepare the foam quenching additive, and its weight percent composition is as follows:

[0018]

[0019] Dissolve the prepared foam coke quenching additive in water at a ratio of 1:19 to prepare an aqueous solution with a concentration of 5% by weight, and then pour the high-concentration aqueous solution and water at a ratio of 1:200 for coke quenching after 10 minutes. Pool, prepare a dilute aqueous solution with a concentration of 0.025% by weight, then pump the dilute aqueous solution into the sprayer, and spray it on the high-temperature red coke. When the temperature of the coke drops below 200°C, stop the spraying and withdraw the coke .

Embodiment 3

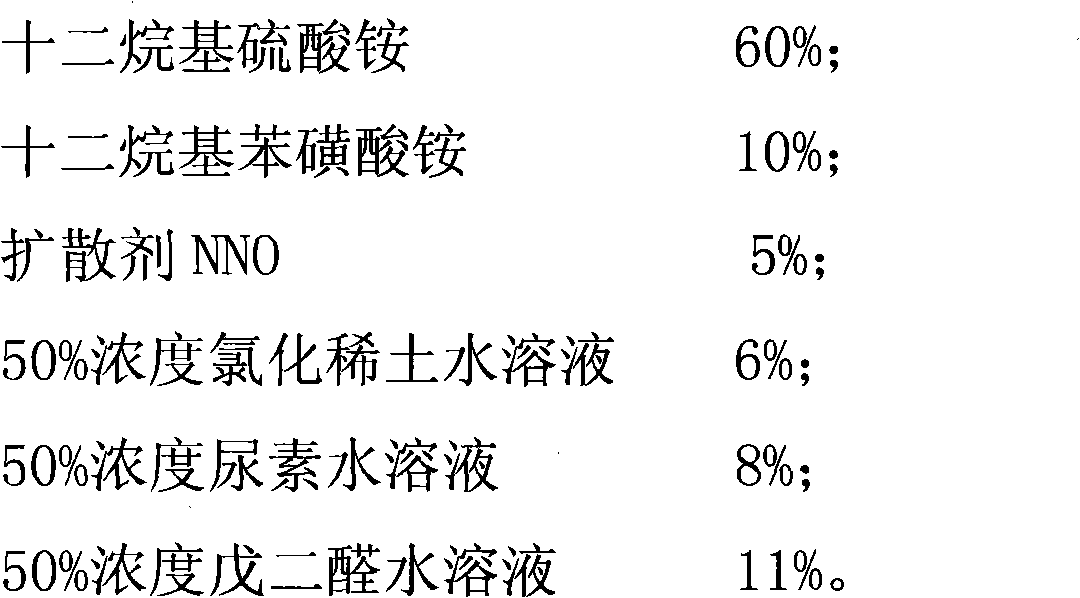

[0021] First prepare the foam quenching additive, and its weight percent composition is as follows:

[0022]

[0023] Dissolve the prepared foam quenching additive in water at a ratio of 1:4 to prepare an aqueous solution with a concentration of 20% by weight. After 10 minutes, pour the high-concentration aqueous solution and water into the coke quenching pool at a ratio of 1:200 , prepared into a dilute aqueous solution with a concentration of 0.1% by weight, then pump the dilute aqueous solution into the sprayer, and spray it on the high-temperature red coke. When the temperature of the coke drops below 200°C, stop the spraying and withdraw the coke.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com