High-efficiency composite fume purifier with alternating electric field

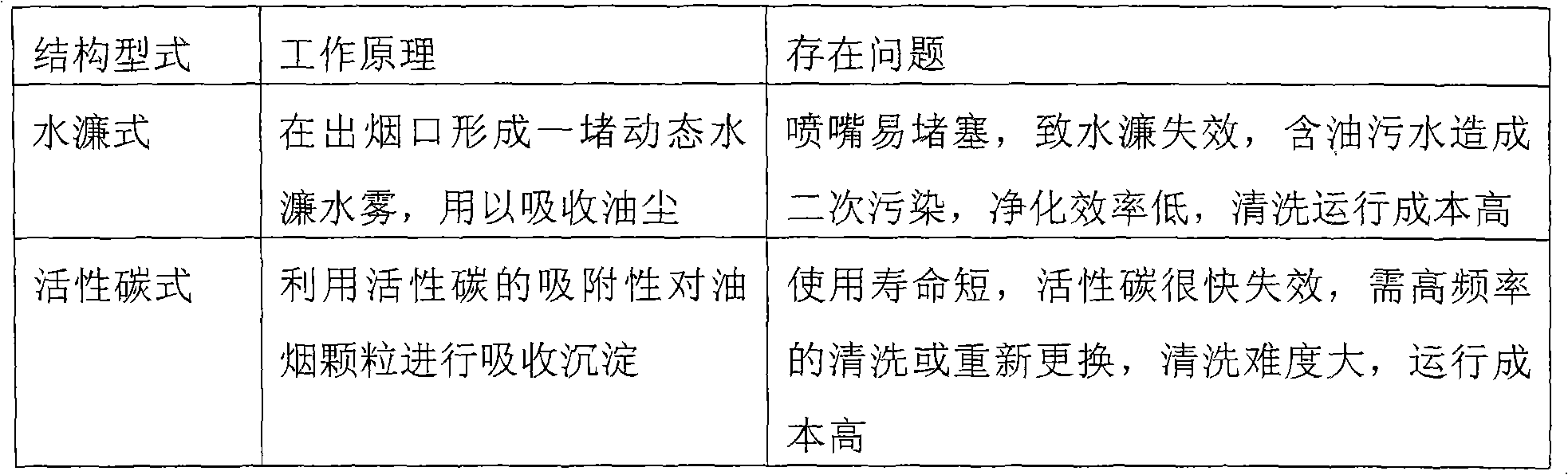

A lampblack purifier and alternating electric field technology, applied in the direction of lampblack removal, electrostatic effect separation, external electrostatic separator, etc., can solve problems such as increased concentration of lampblack emission, fire, and easy film accumulation on the electrode plate surface, etc., to achieve lampblack removal High efficiency, accelerated settlement, and the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

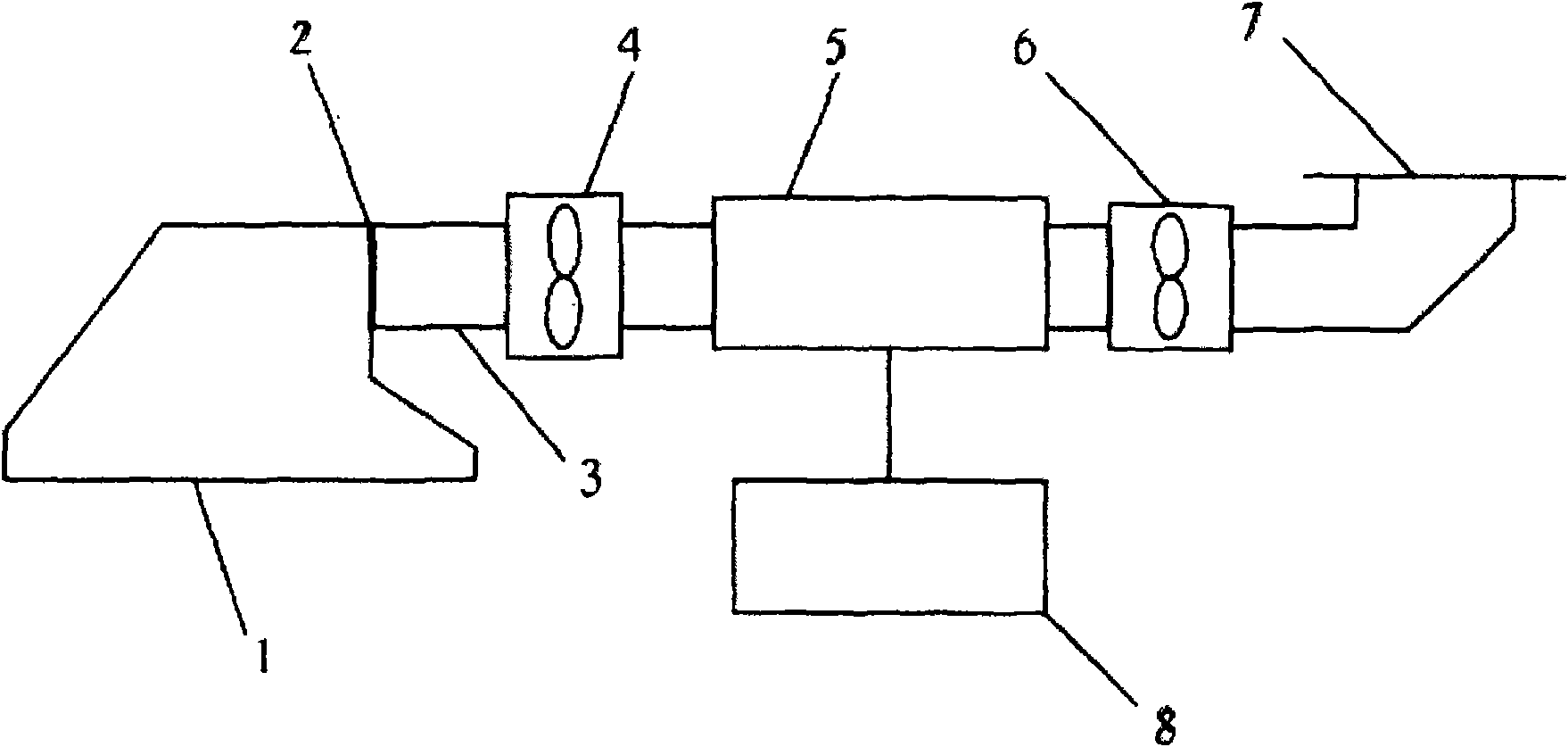

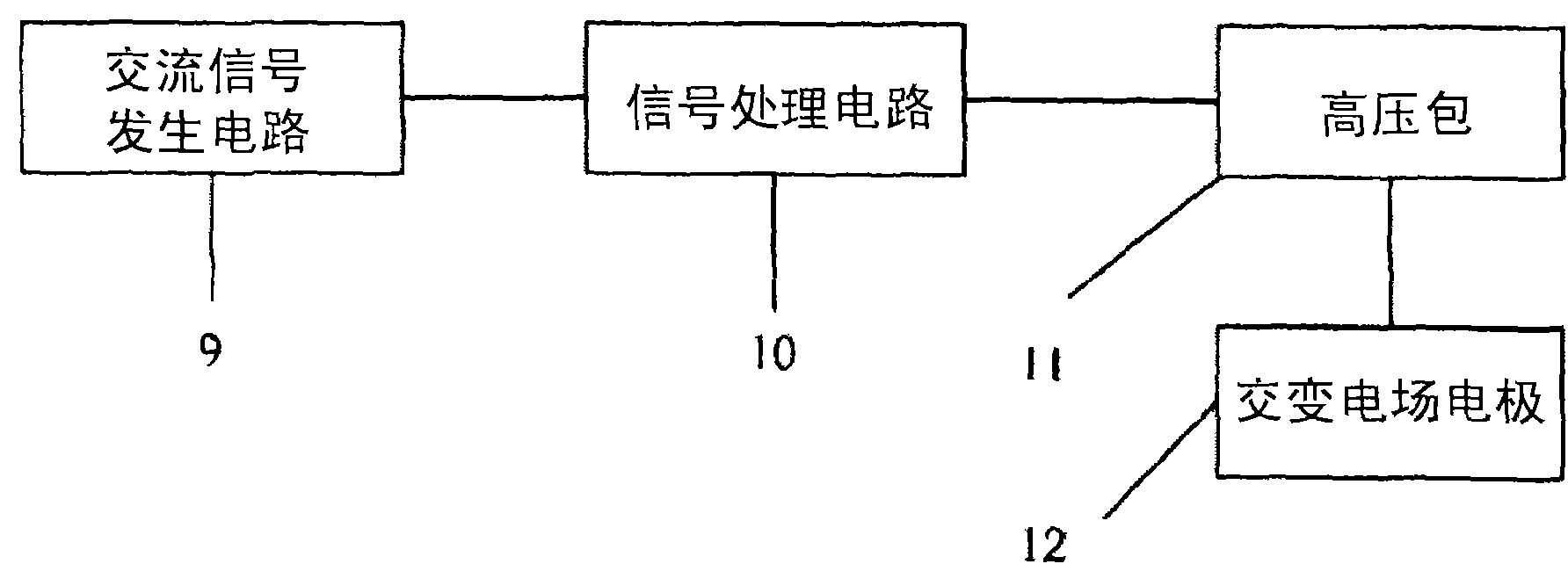

[0023] Such as figure 1 The high-efficiency composite oil fume purifier with alternating electric field shown in , including oil collection hood, exhaust fan, oil collection tank, flue pipe, fire grille, purification unit, exhaust fan, electric control box, is characterized in that it is installed in the flue The purification unit or magnetoelectric composite purification unit 5 in the pipe 3 includes an alternating signal generating unit 8, an alternating electric field electrode 12 and a high voltage pack 11, the output electric signal of the high voltage pack 11 is an alternating voltage signal, alternating A pulsating alternating electric field is formed between the two poles 12 of the electric field, the output end of the alternating signal generating unit 8 is electrically connected to the input end of the high voltage pack 11 , and the output end of the high voltage pack 11 is connected to two alternating electric field electrodes 12 respectively. The inter-electrode vo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com